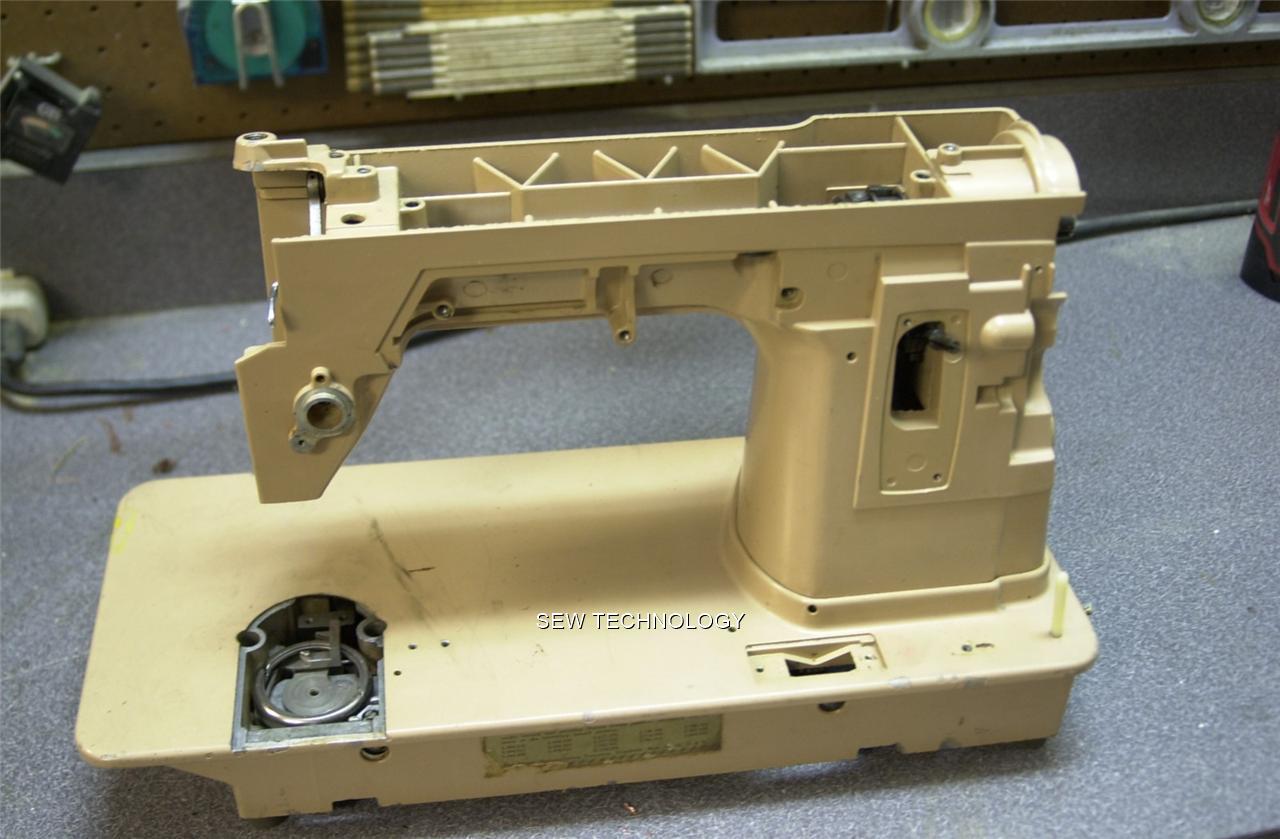

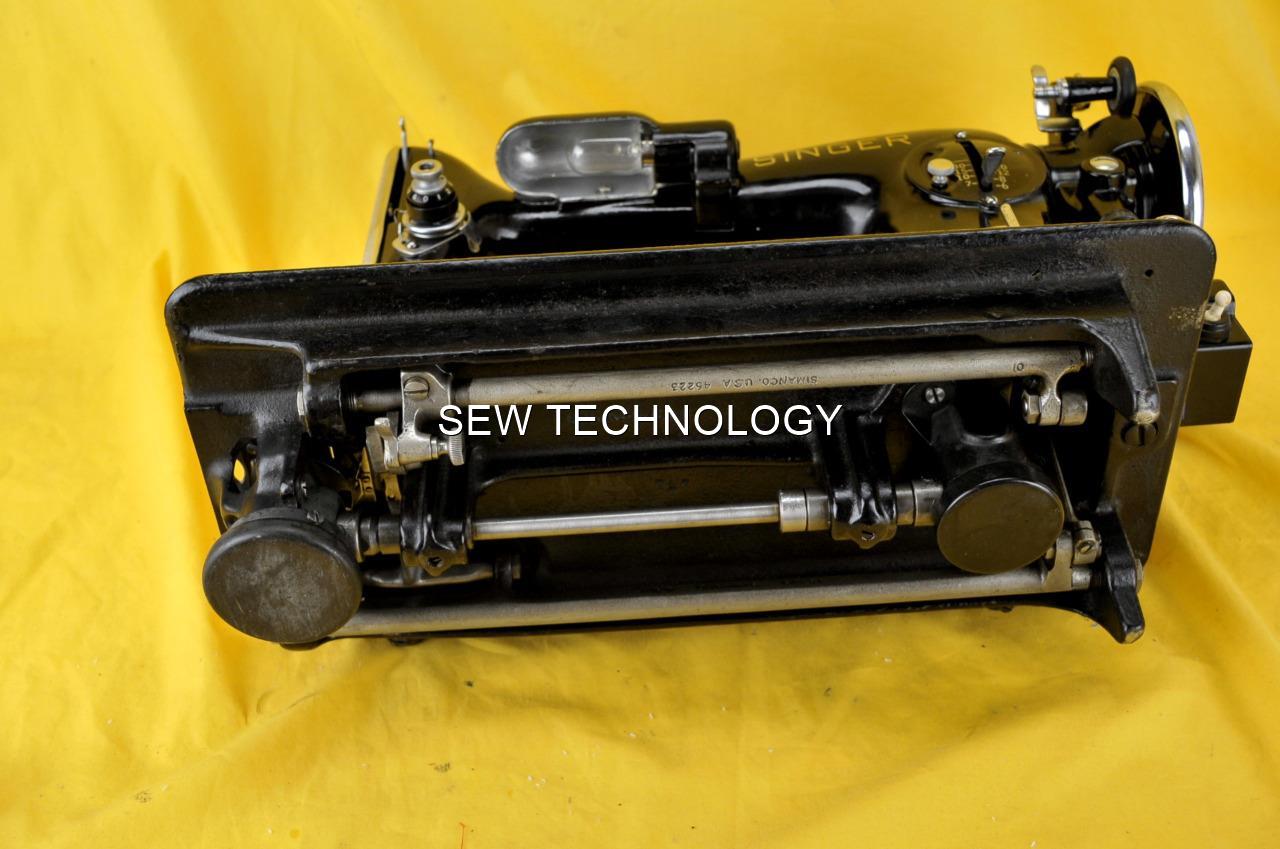

The Singer 301 or 301 is a lightweight aluminum straight stitch sewing machine sold during the fifties. Loved by quilters for its lightweight portability, larger bed, smooth gear drive, powerful motor and slant needle design which provides better visibility of the work area and more leverage for the machine to sew through anything that fits under the foot. It is a reliable sturdy machine which utilizes same motor as the 401 made portable with its own built in handle, gear driven, all metal parts, full rotary hook, feed dog drop and larger opening under the arm for sewing bulky materials.

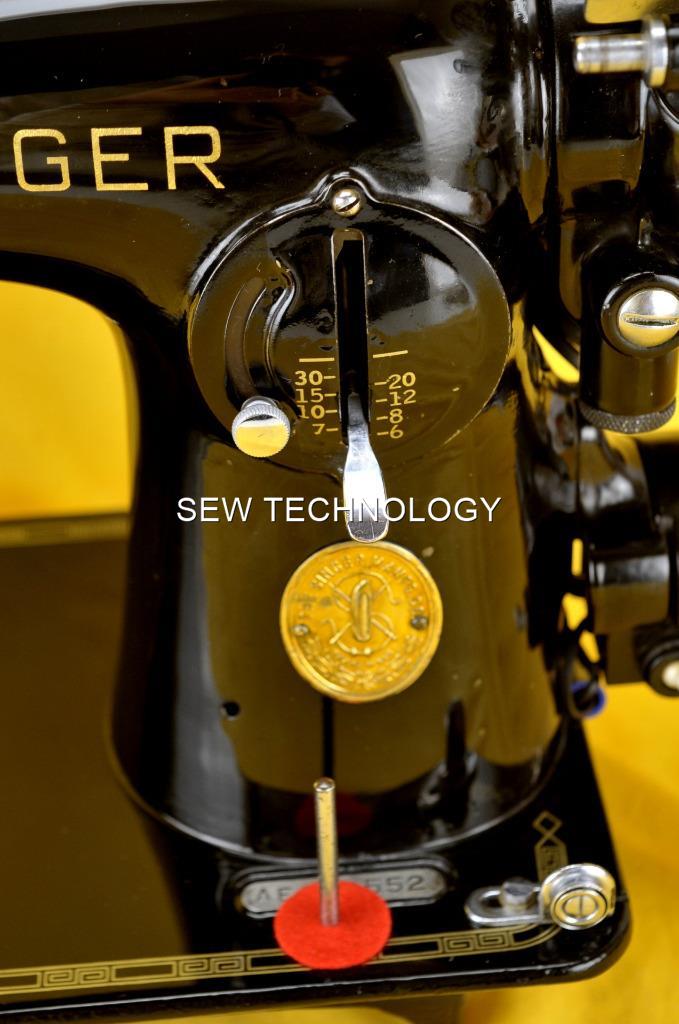

The Singer 306 is an industrial strength zigzag machine most doing straight and zigzag stitches while some variants had cams for decorative stitches and were the precursor to the 401 series. It came with a built in bobbin winder and adjustive stitch length from 6-30, adjustable tension system and needle position, rotary hook, adjustable pressor foot and all metal construction.

The Singer 401 is a sturdy built zig zag machine featuring an all metal construction, top loading drop in bobbin and smooth rotary hook. It has the ability to produce many decorative stitches with the built in cam stack and additional external cams making this an extremely versatile machine. The internal cam stack allows over 60 stitch designs and variations by adjusting the 2 front selector knobs. In addition, removable top hat cams are available to create 60 more stitch variations. The 401 is considered by many to be the best that Singer ever built with good piercing power in an all metal gear driven machine which means no plastic gears, no belts to break- not available in today's plastic market. The 401A Slant-O-Matic feature moves the needle over 1 inch closer to the operator providing good visibility for the work surface and easier threading. It also features an adjustable presser foot along with tension regulator knob for ease in adjustment and ability to accept two threads for twin needle sewing.

The Singer 500A or 500 Rocketeer was the evolution from the highly successful 401 series machines. The 500 series is a zigzag machine with internal design disks featuring all metal components, gear driven with slant needle retaining the same motor, drive, cam and hook systems from the 401. The main changes were an internal bobbin winder, additional thread take up, dialed presser foot tension, intermediate position on the throat lift plate for darning or free motion sewing and a redesigned top lid with fold down spool holders.

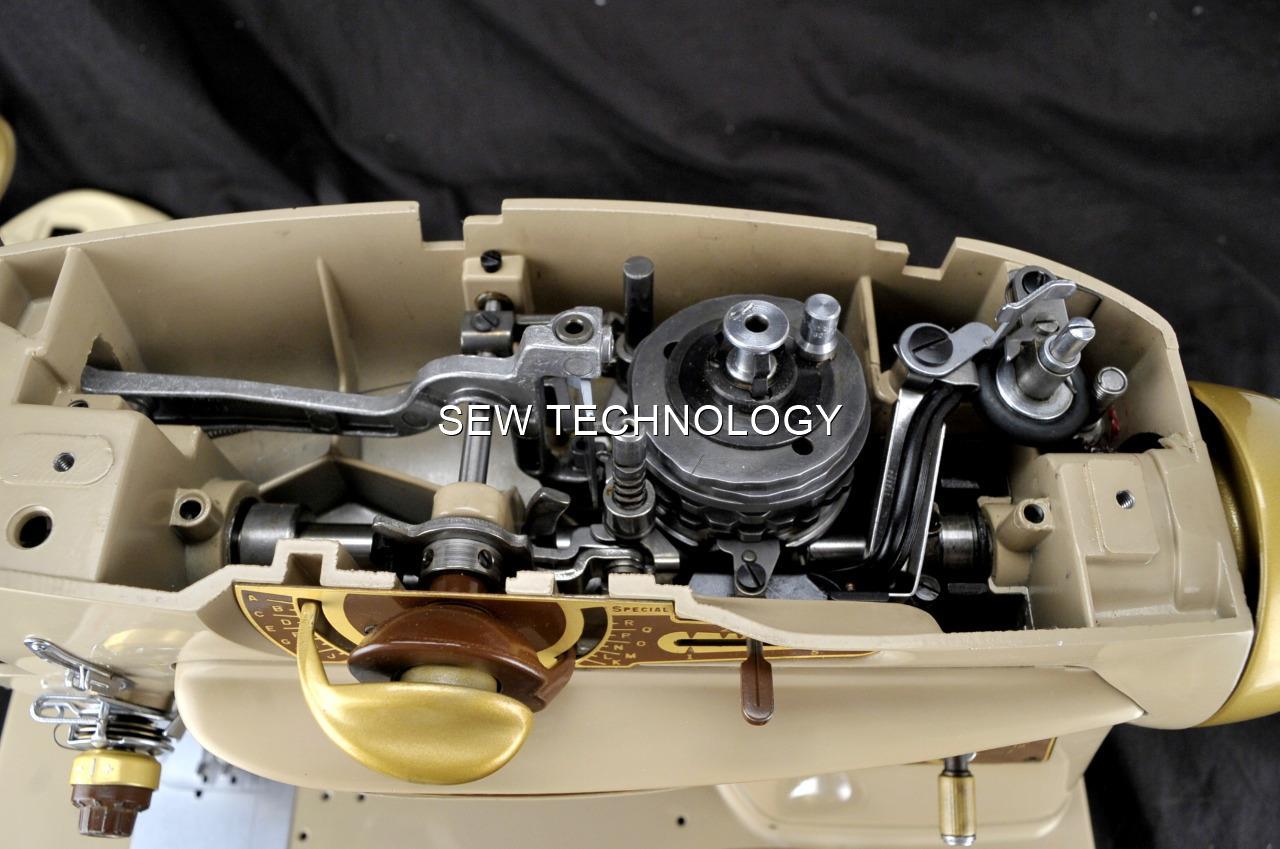

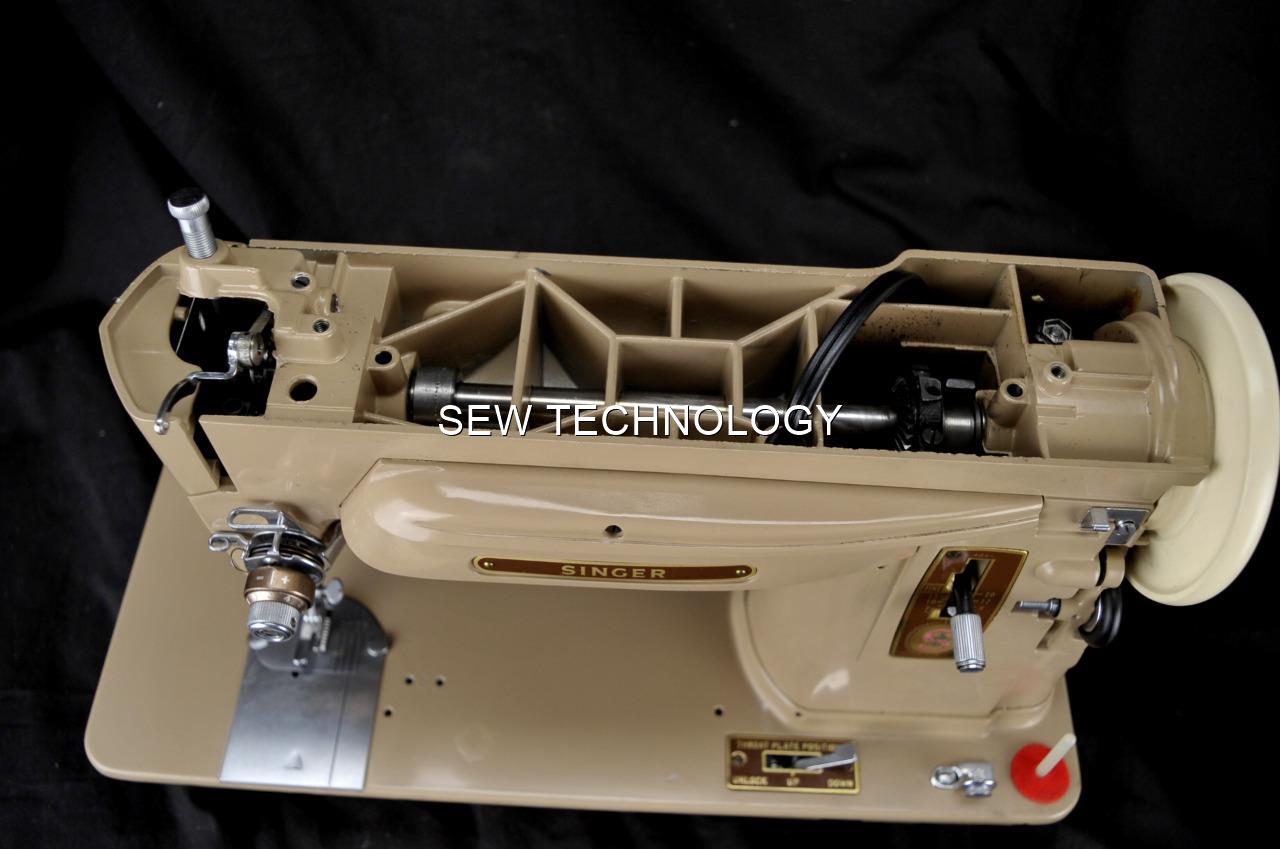

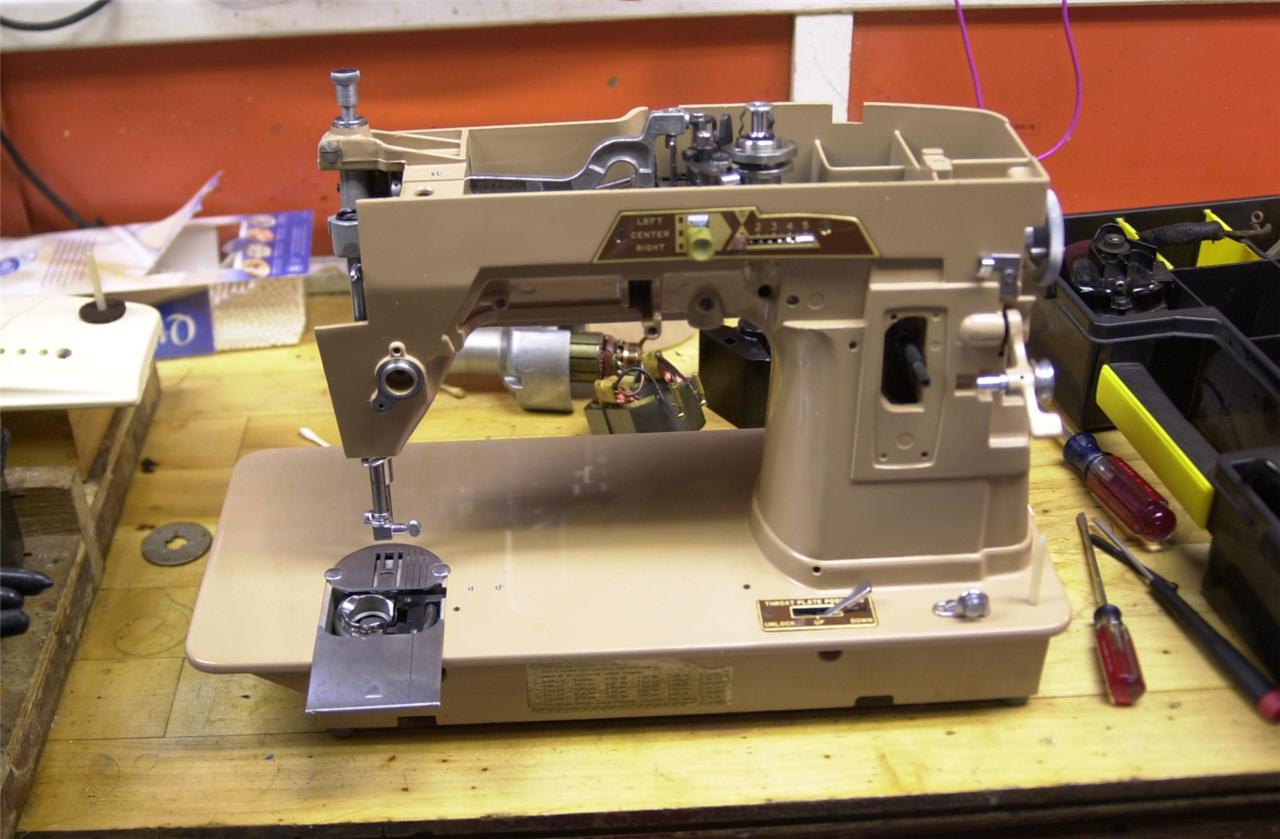

THIS IS A EXCELLENT SINGER 500A SEWING MACHINE

The Singer 500 was the evolution of their highly successful 401 series machine. In the late 50's and 60's, Singer decided to jump into the streamlining "Space Age" craze that was sweeping the country. With minor exception, the 500 was a 401 with a different case.

The 500A Slant-O-Matic feature moves the needle over 1-inch closer to the operator. The average bed is 7 inches wide and the needles are usually centered. On the Slant-O-Matic, the needle is less than 2-1/2 inches from the edge of the bed.

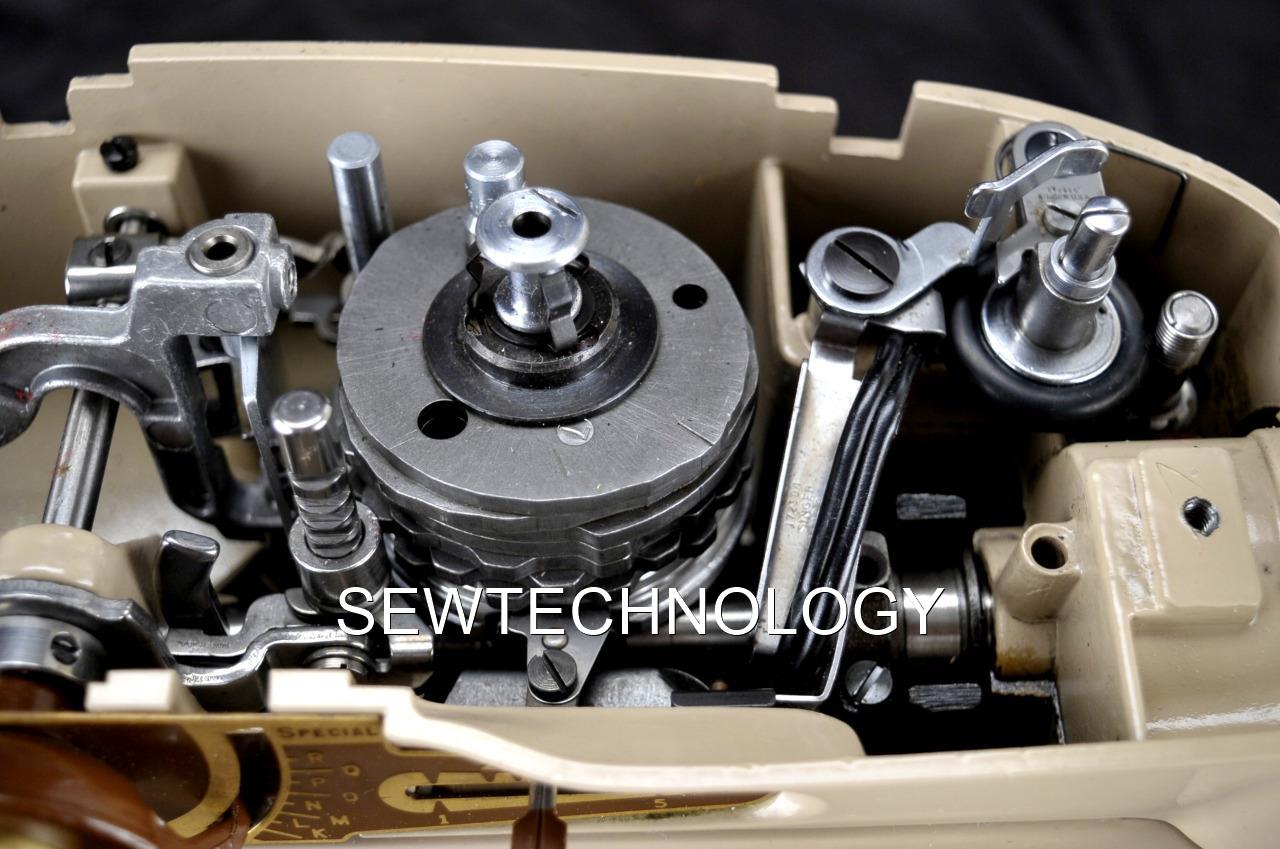

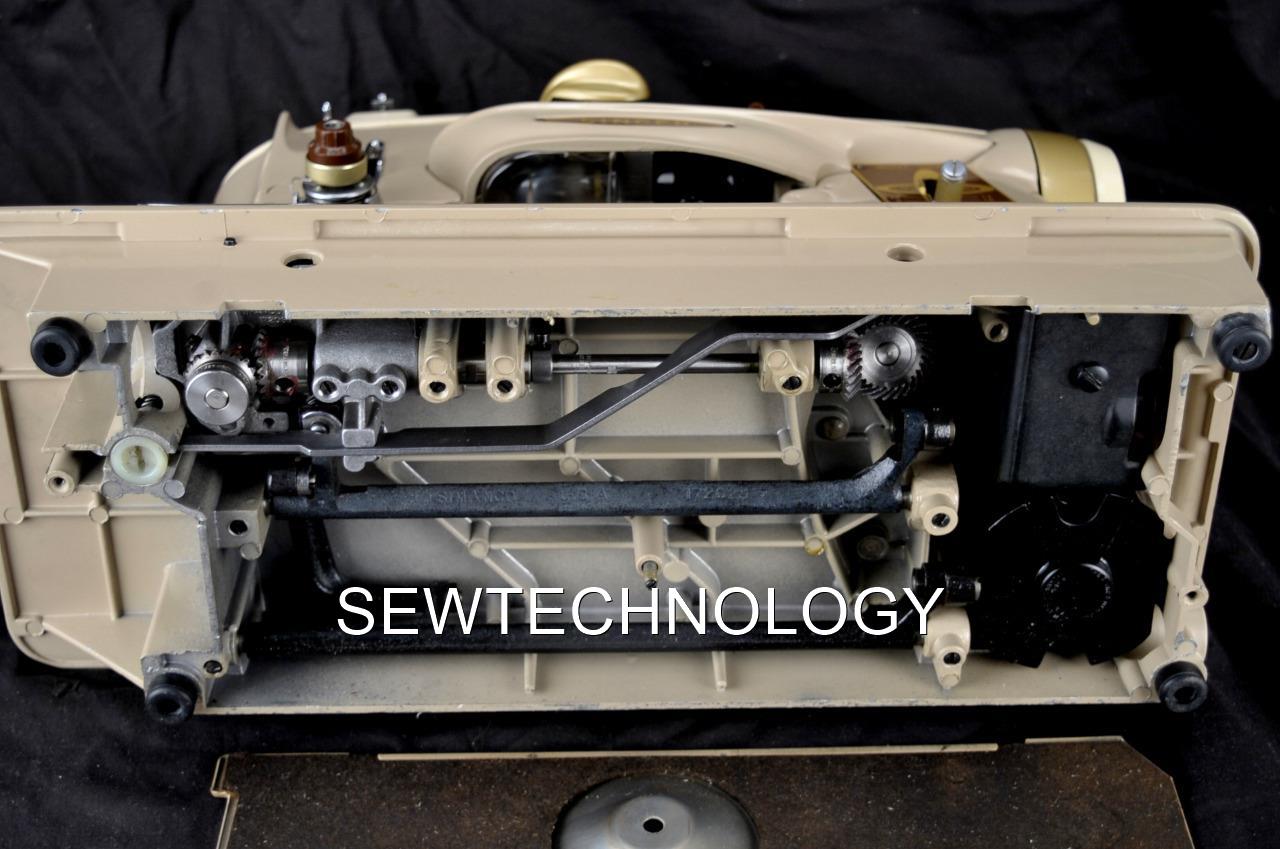

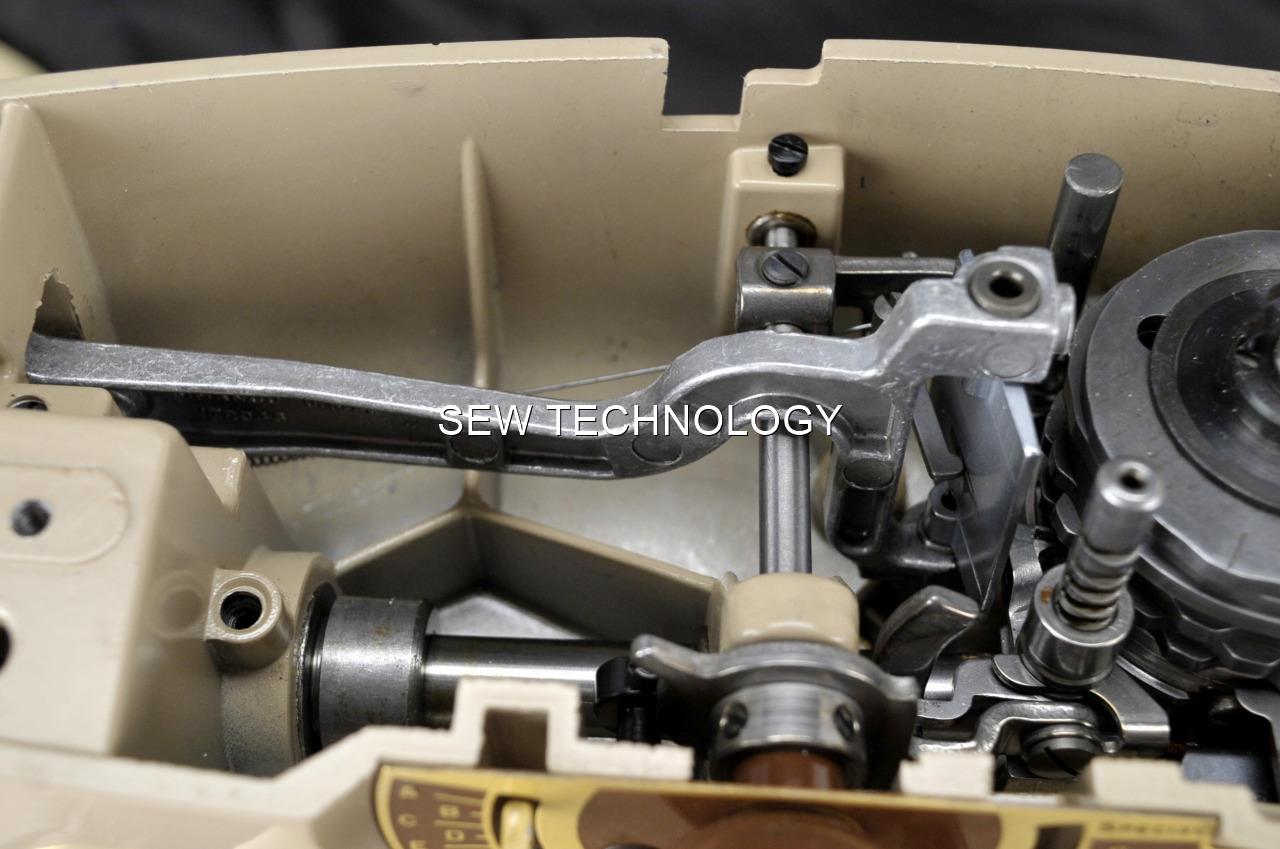

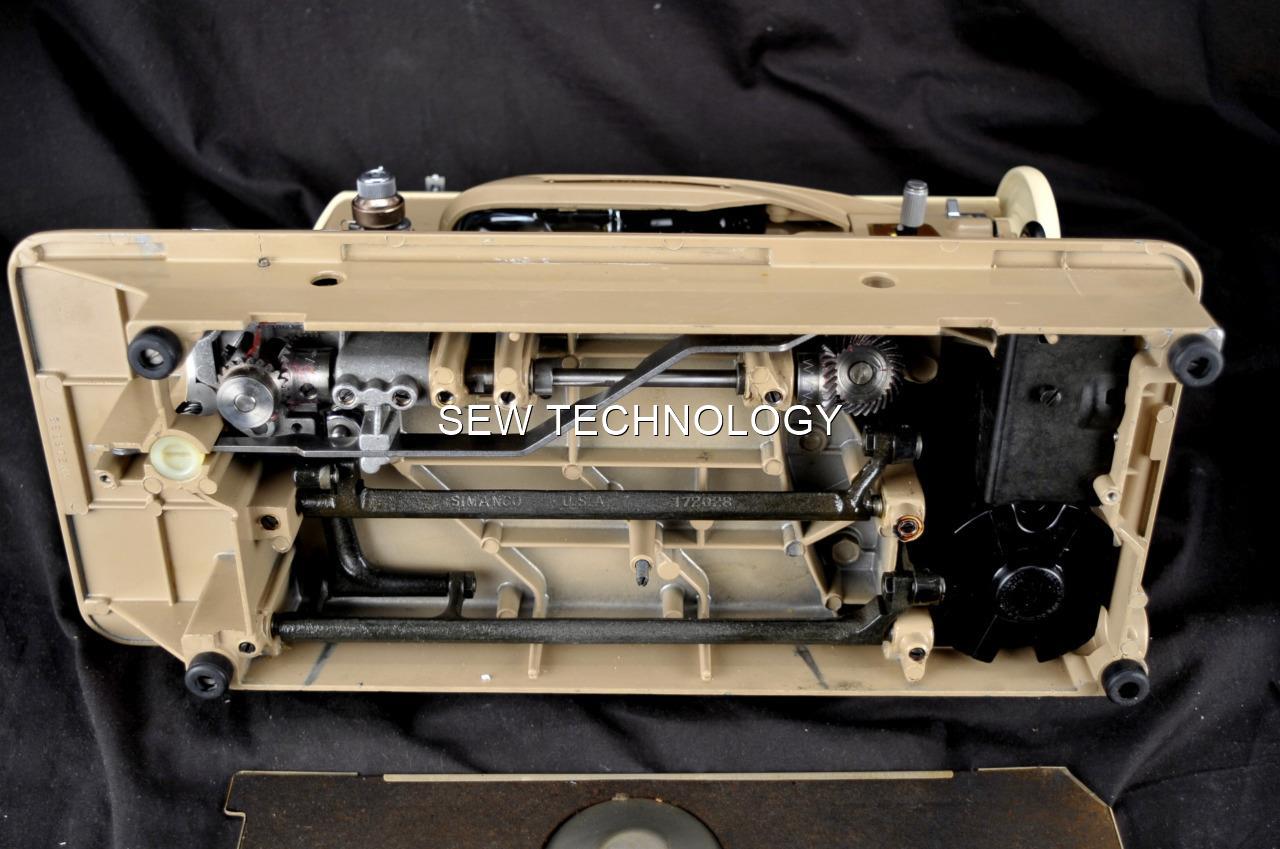

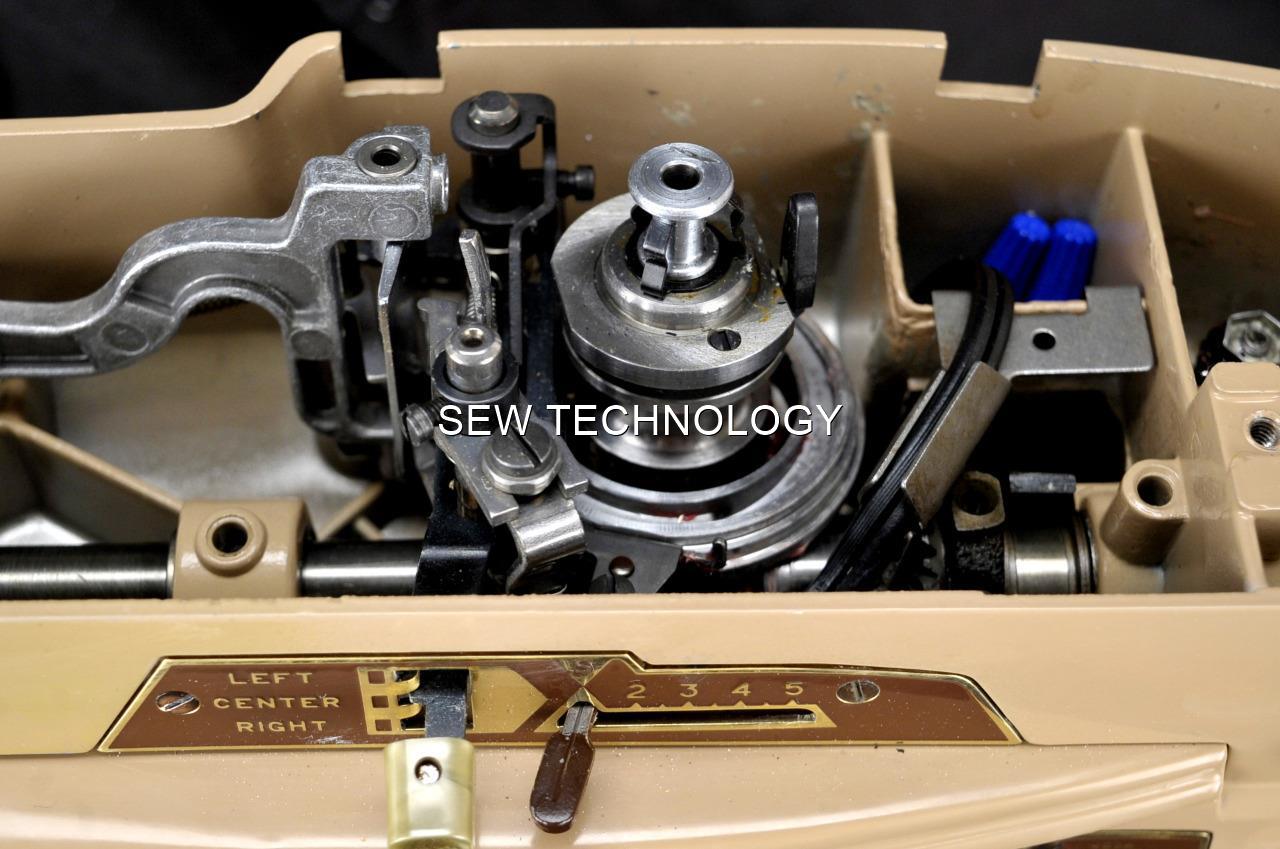

The machine features a all metal gear driven slant needle, zig zag design with internal design disks. The 500, or Rocketeer, was the later version of the Singer 401, with a few minor changes. Most of the changes were cosmetic, the motor, drive, cam, and hook system remained the same. The major changes were:

The bobbin winder was changed to an internal design

An additional thread take up was added

The presser foot tension was changed to a dial

The top lid was changed and incorporated fold down spool holders

An intermediate position was labeled to the throat lift plate for darning or free motion sewing

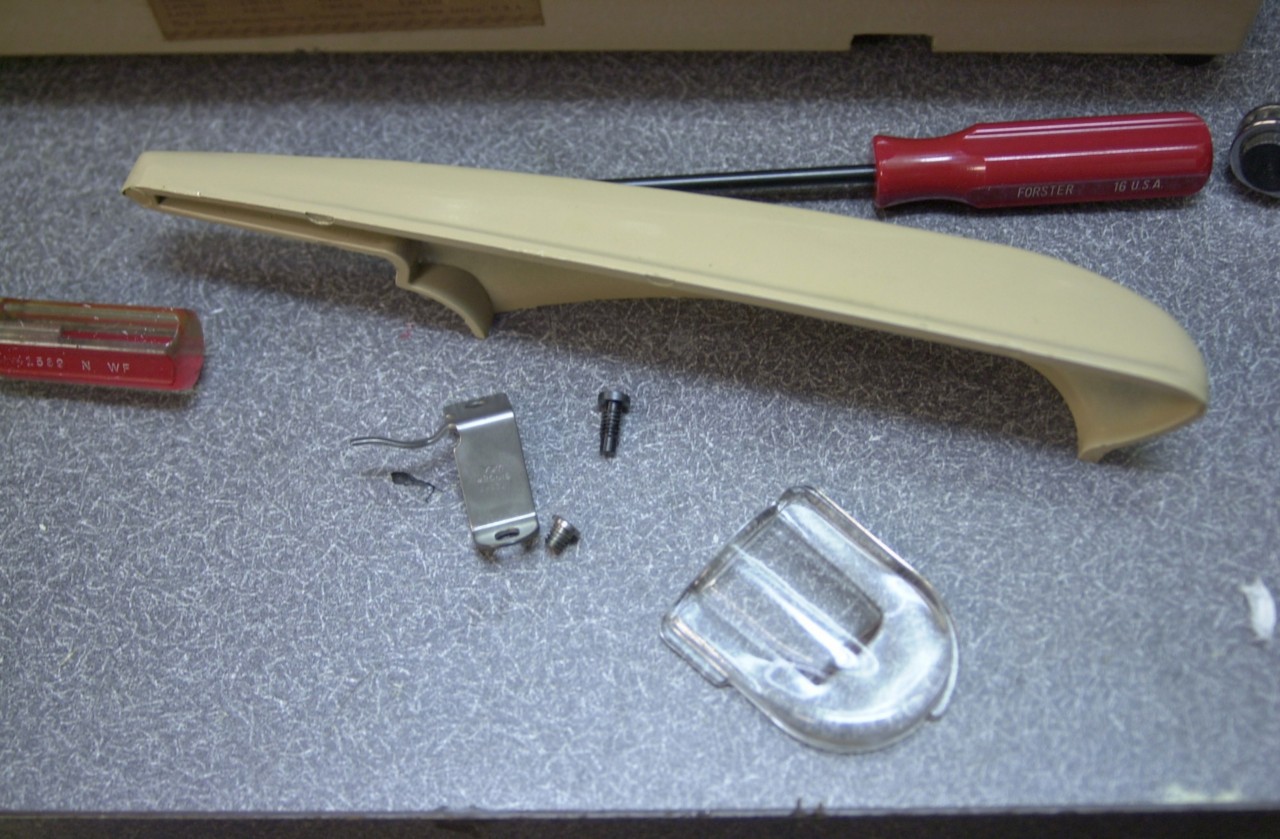

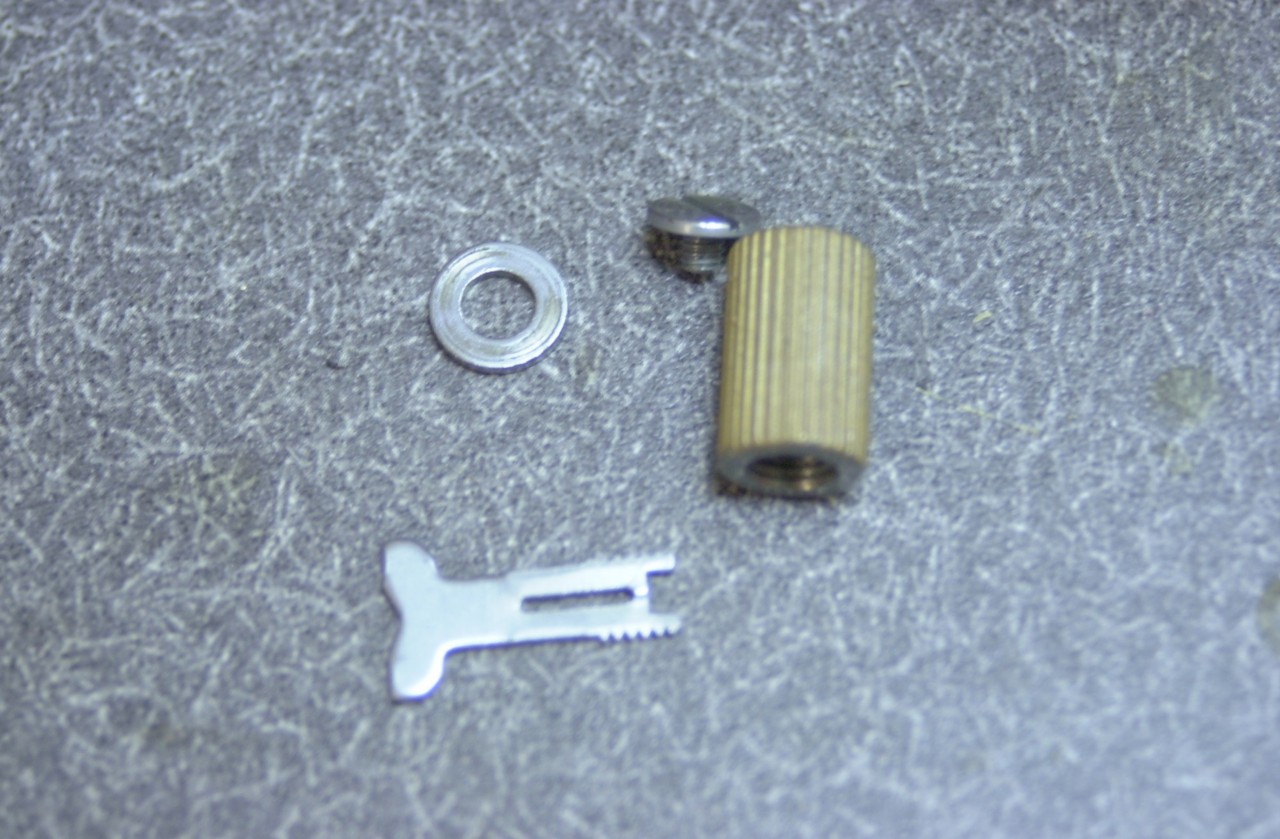

THE REMOVABLE SPOOL HOLDER THAT FITS ON THE TOP OF THE MACHINE IS USUALLY BROKEN OR MISSING, SO WE MACHINE A NEW ONE OUT OF SOLID ALUMINUM, WHICH IS WHY IT IS SILVER IN THE PICTURE

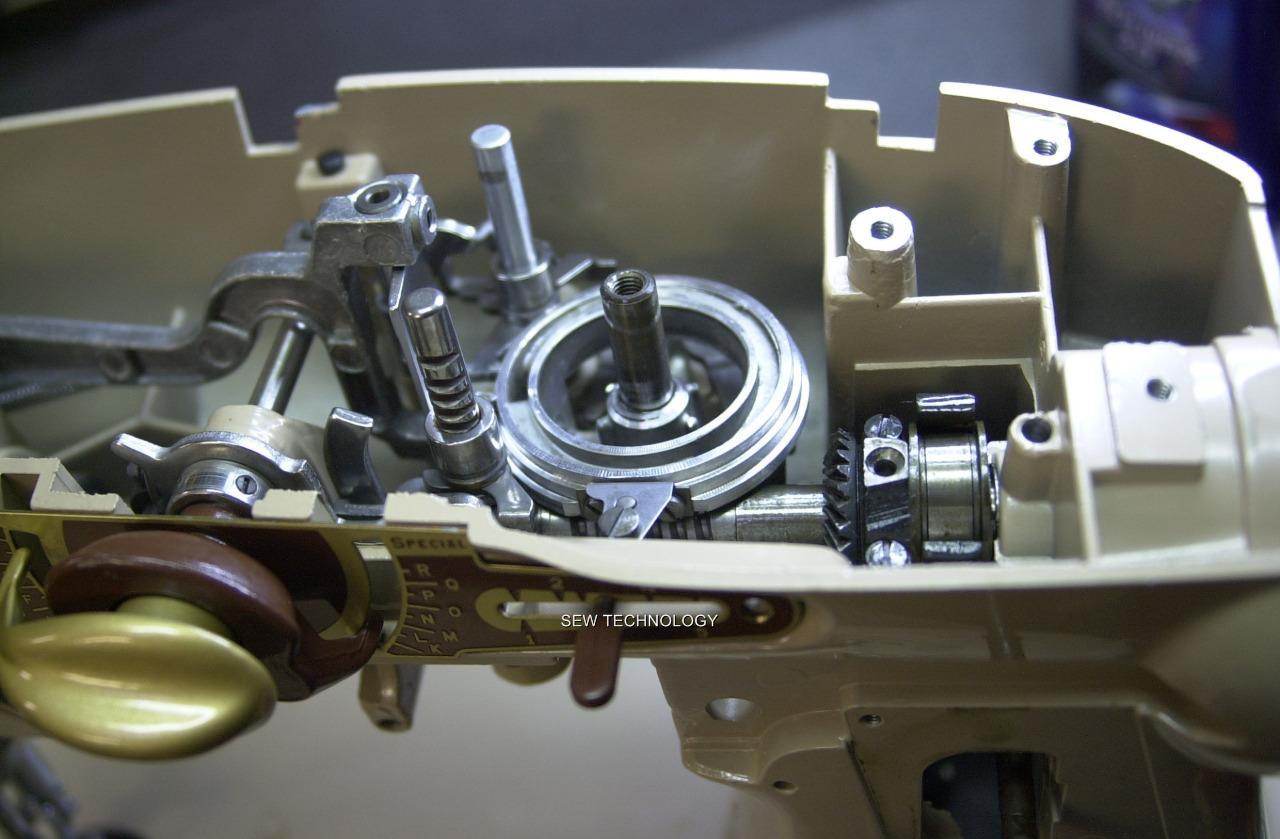

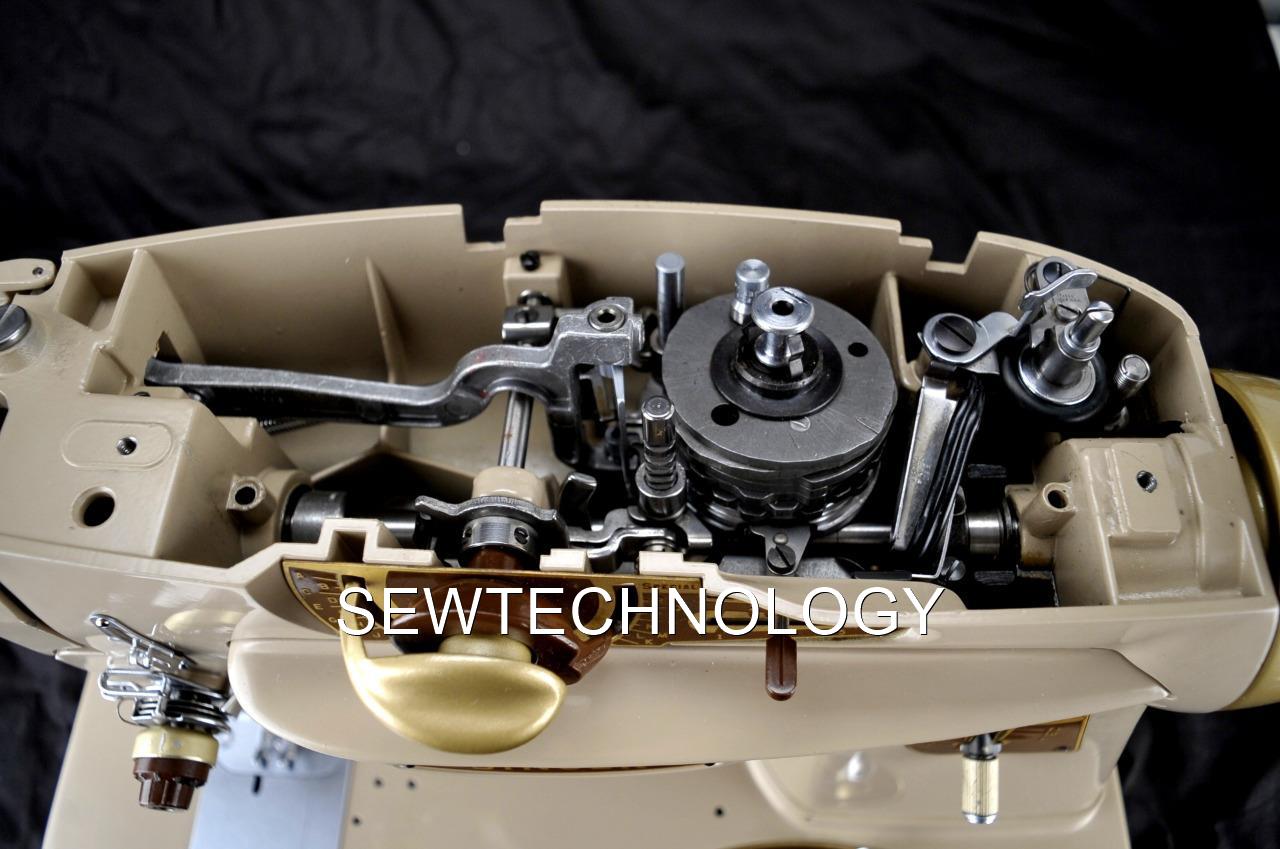

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

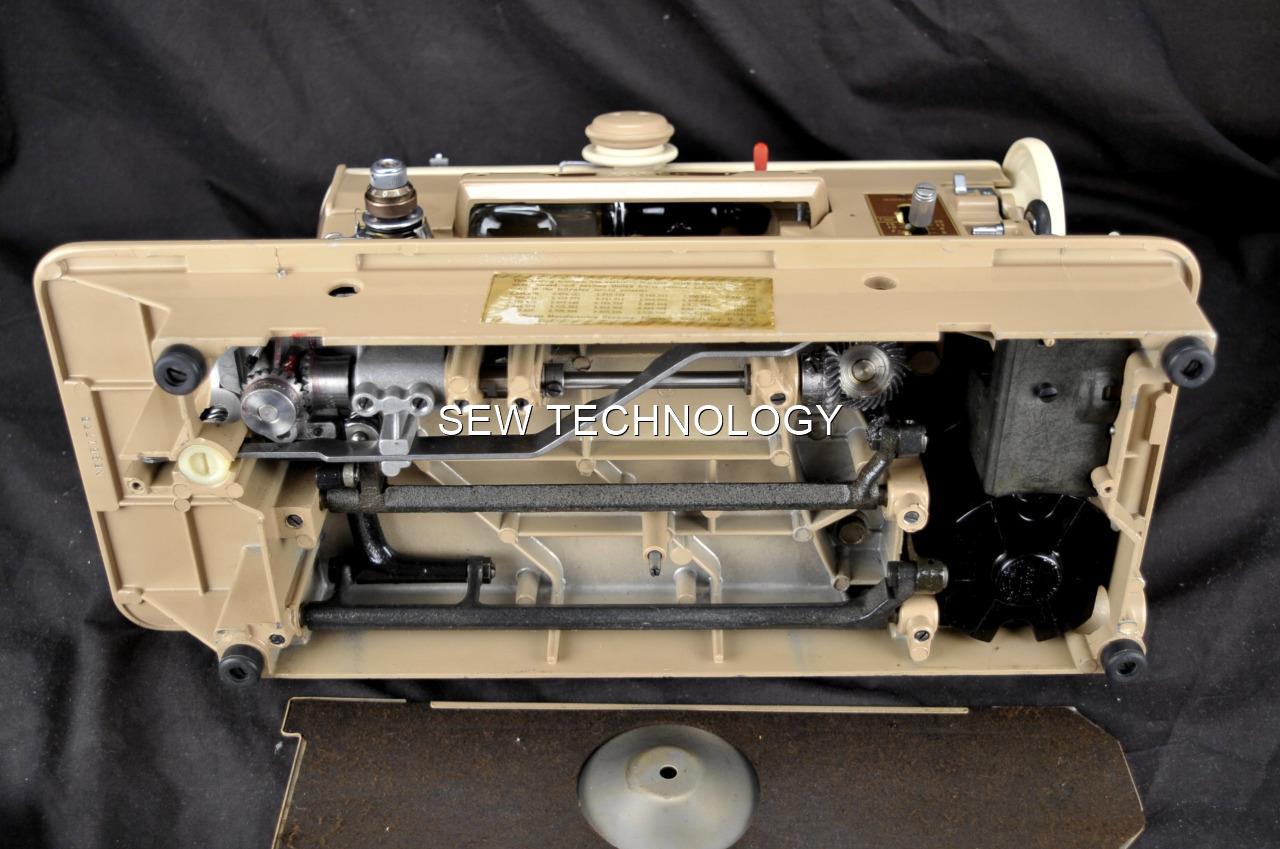

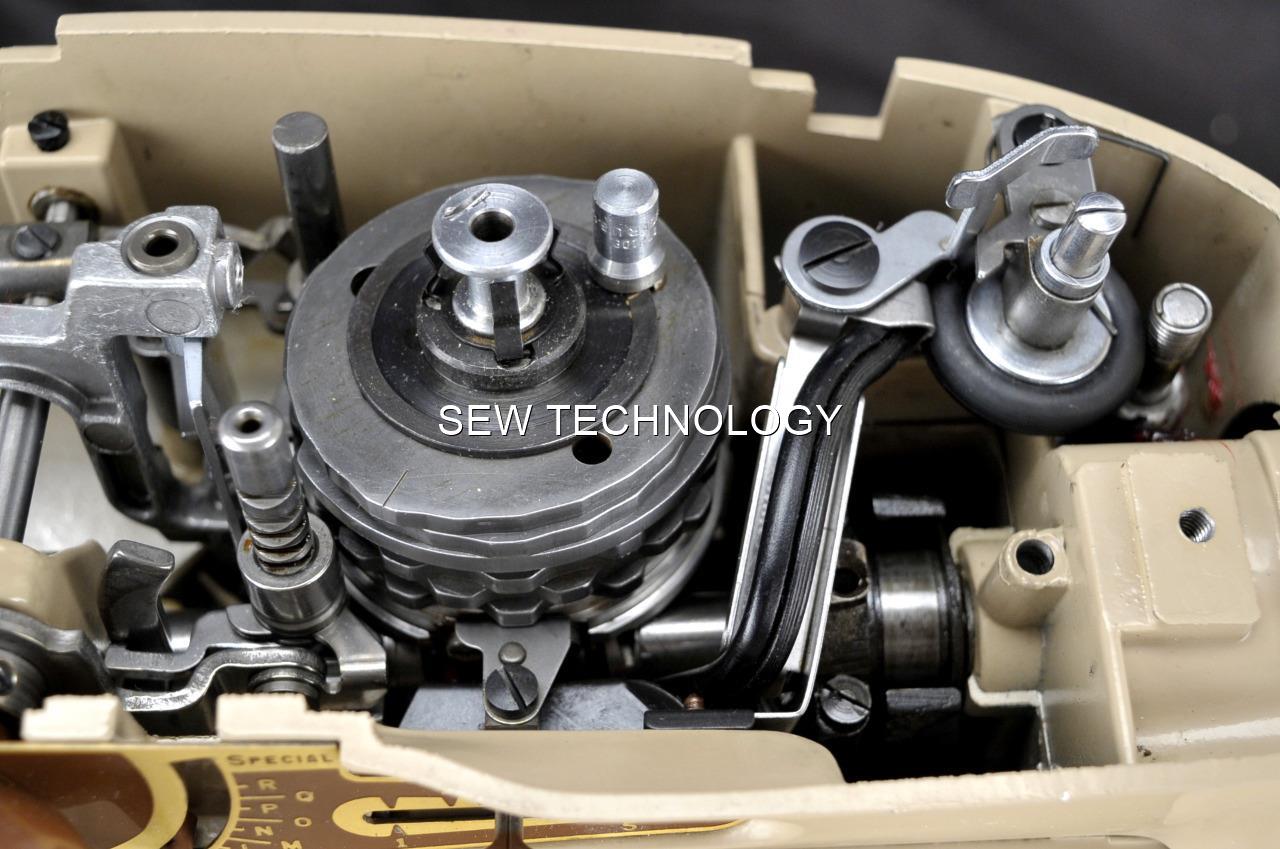

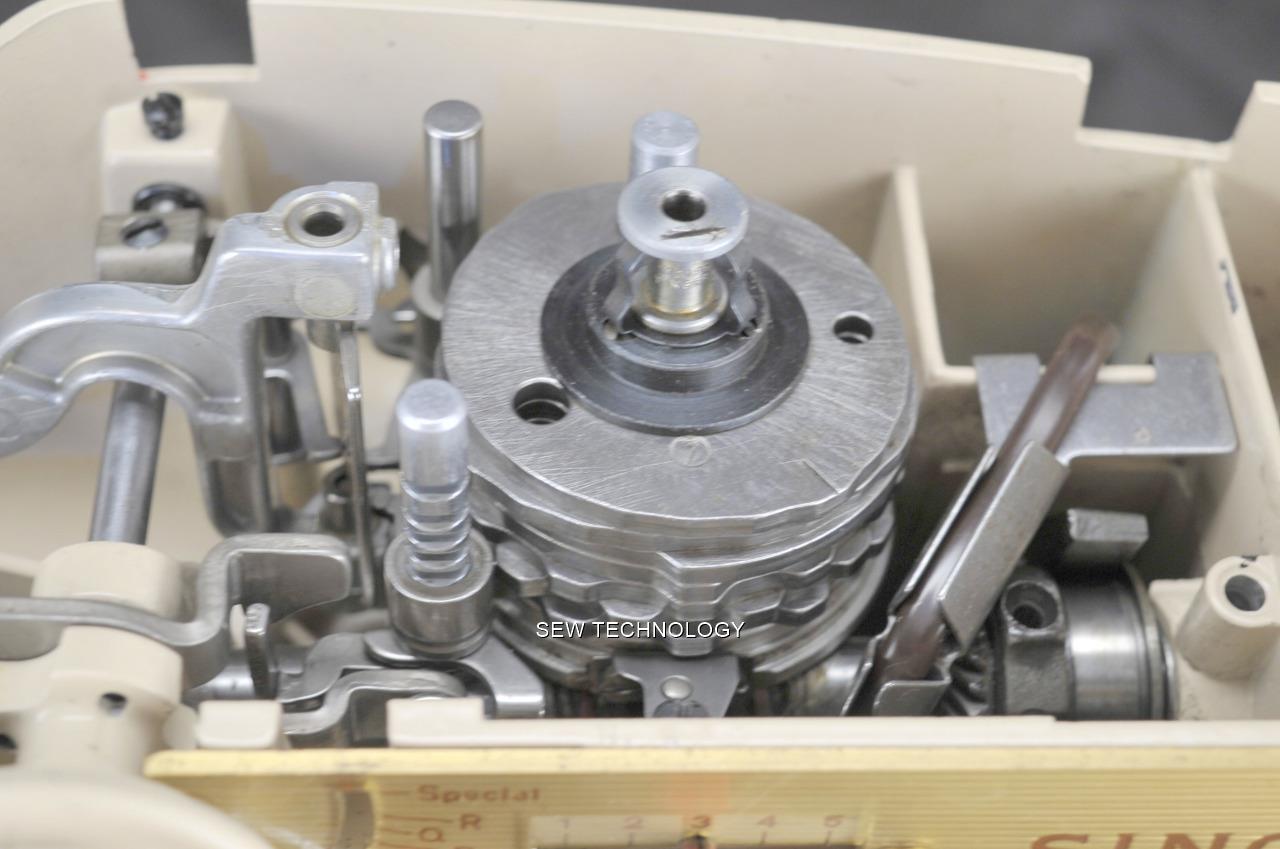

The Singer 500 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary

hook. It’s ability to produce many decorative stitches with the built-in cam stack and additional, external cams make it an extremely versatile workhorse.

IN 1960 THIS MACHINE COST $350...YOU KNOW WHAT IT WOULD COST TODAY?...$0.00...BECAUSE YOU CAN NOT GET AN ALL METAL SEWING MACHINE TODAY...THE ONLY OPTION IS A MACHINE WITH PLASTIC GEARS...THESE ARE NOT THE DISPOSABLE MACHINES PRODUCED TODAY...THESE MACHINES ARE BUILT TO LAST A LIFETIME

THIS 500 IS IN FANTASTIC CONDITION... THIS MACHINE IS IN EXCELLENT MECHANIC AND COSMETIC CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE. SOME PIN SCRATCHES AND MARKS ON BED AND A COUPLE NICKS ALONG THE EDGE OF THE METAL

![]()

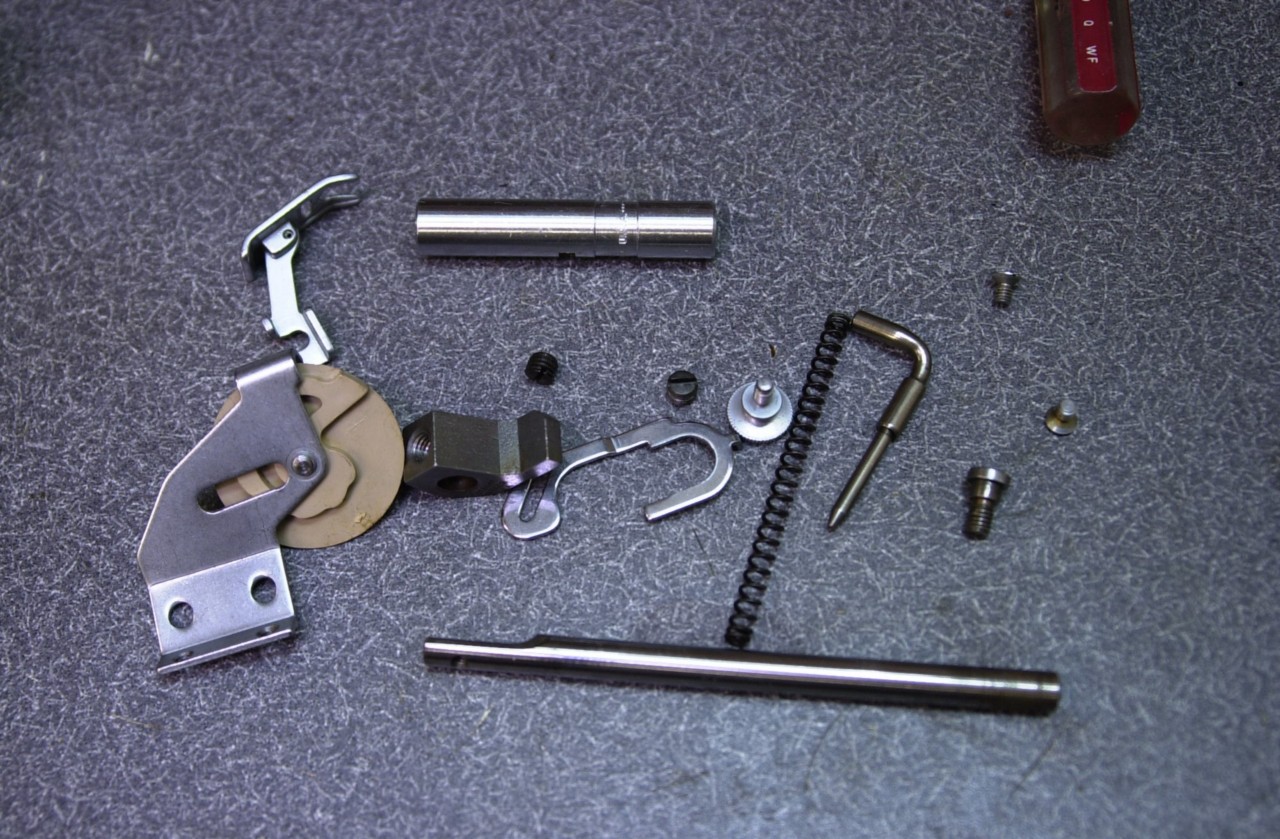

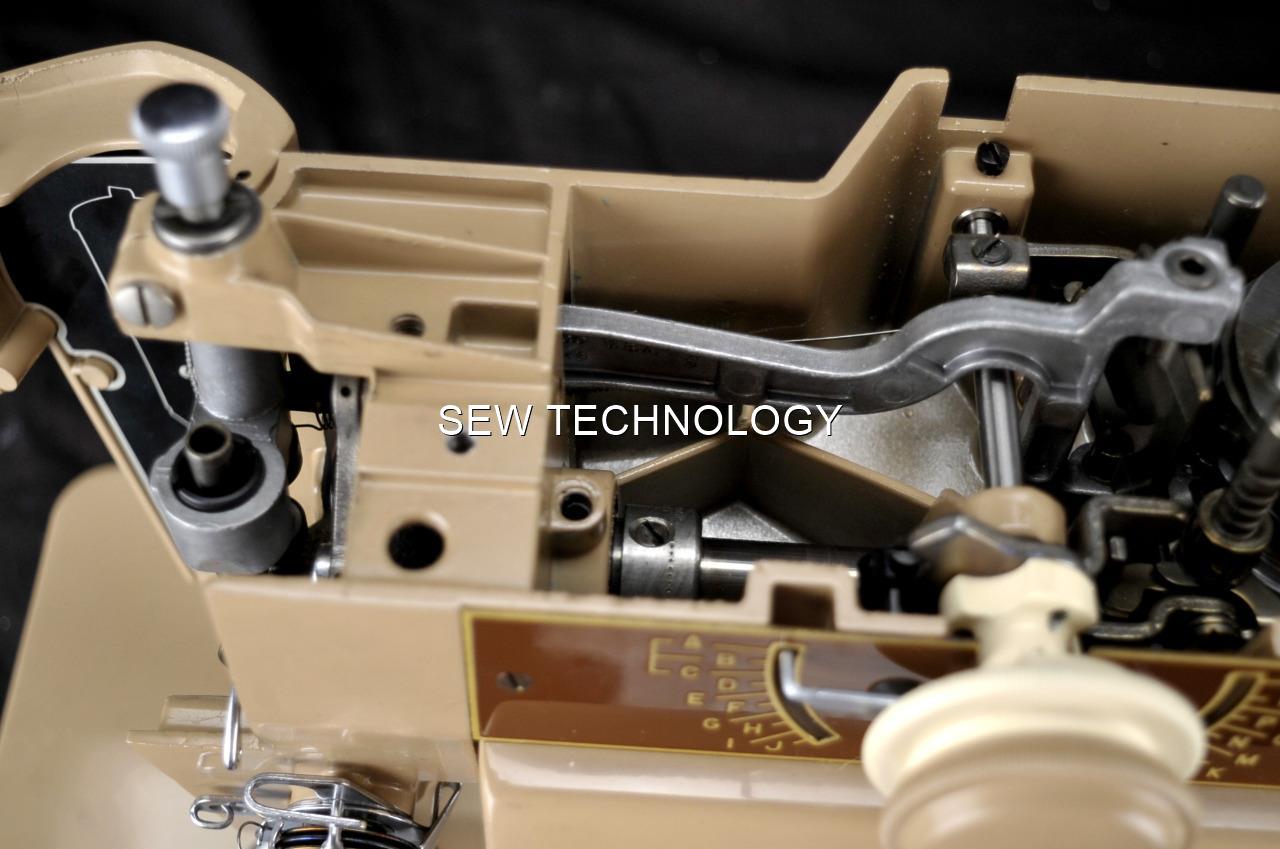

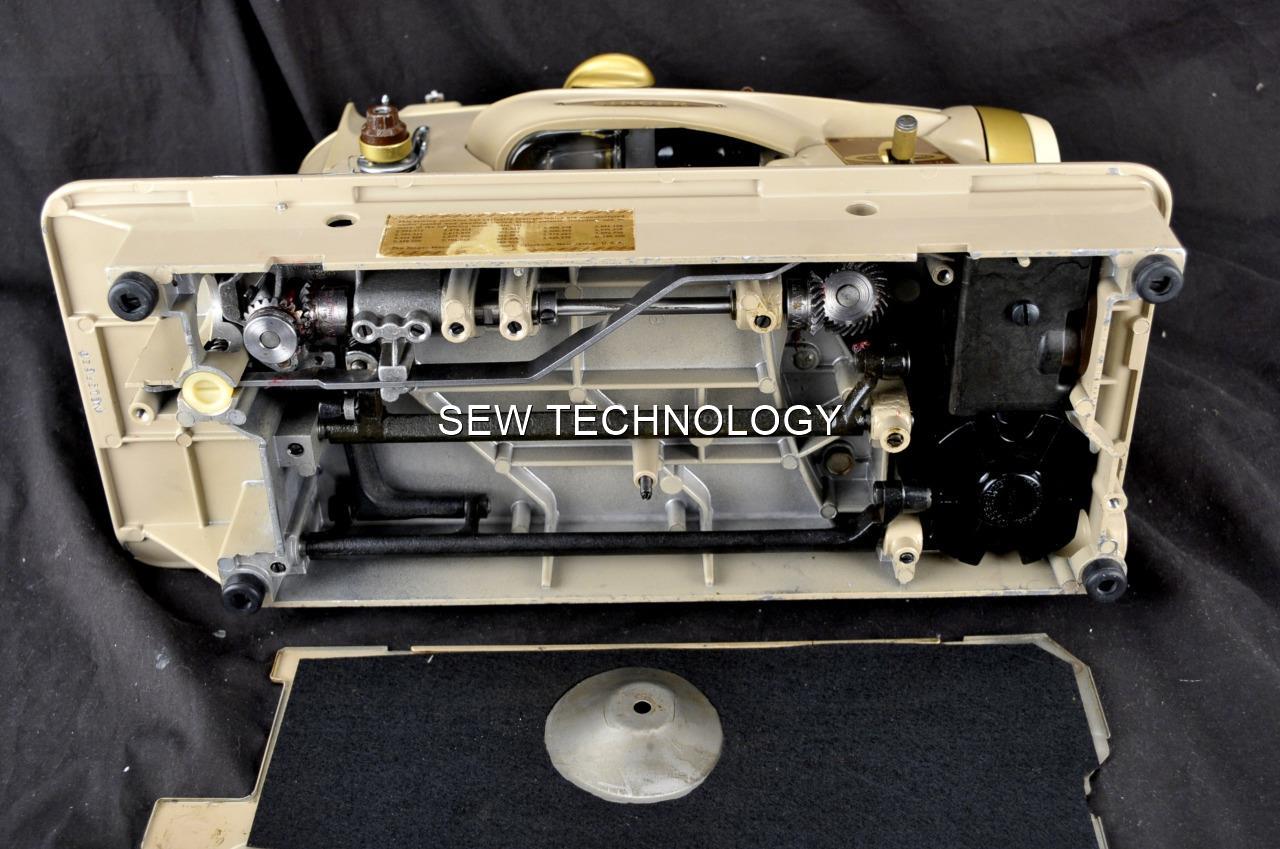

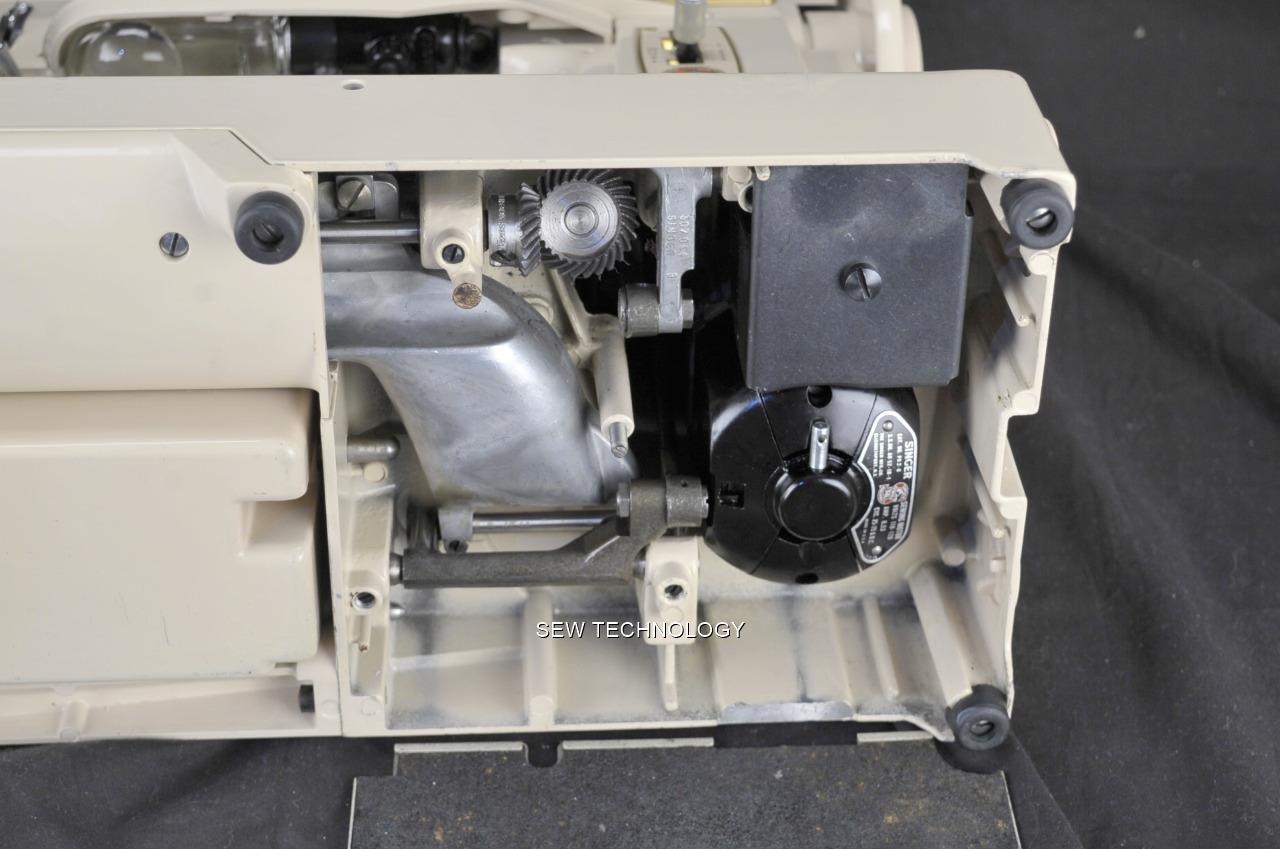

COMPLETELY SERVICED

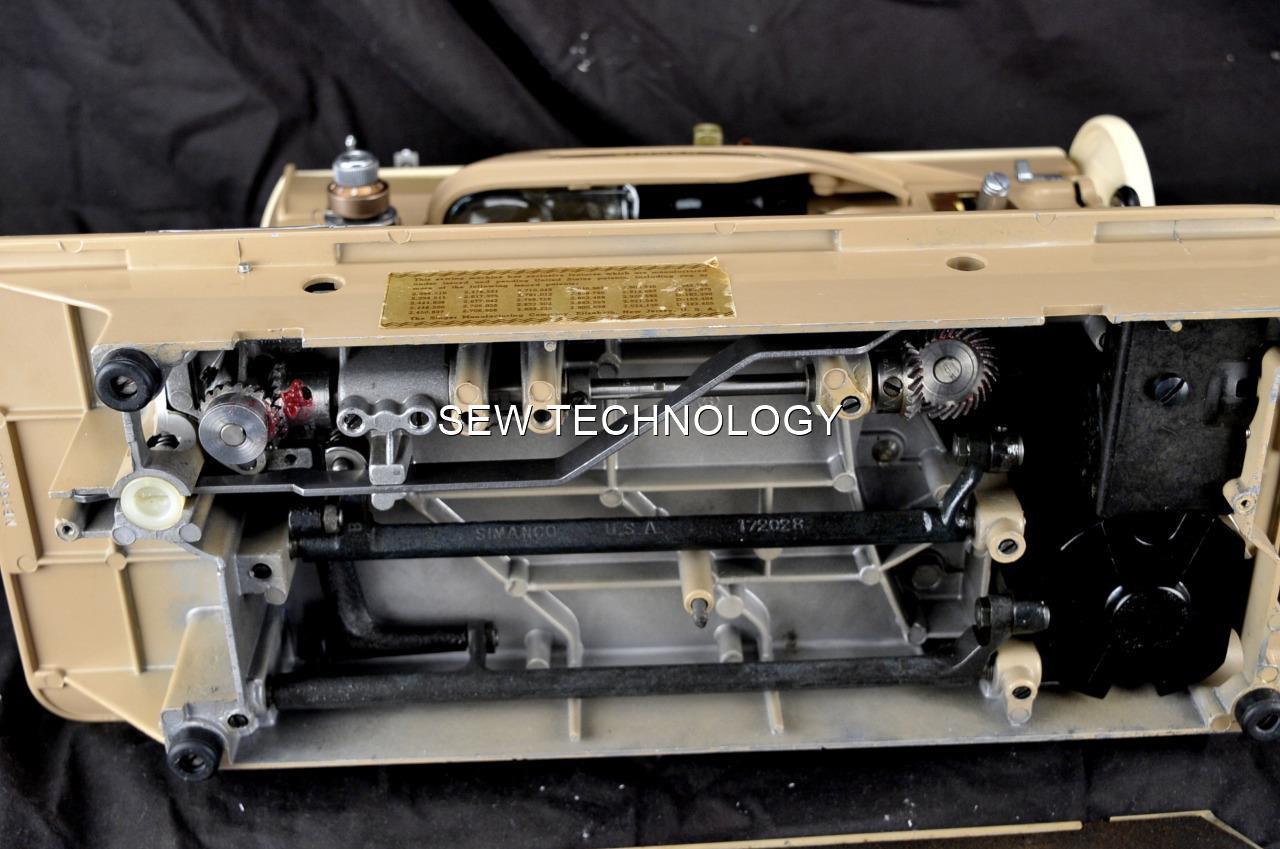

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

MOTOR FULLY SERVICED-- NEW BRUSHES, BEARING, & RESTORATION

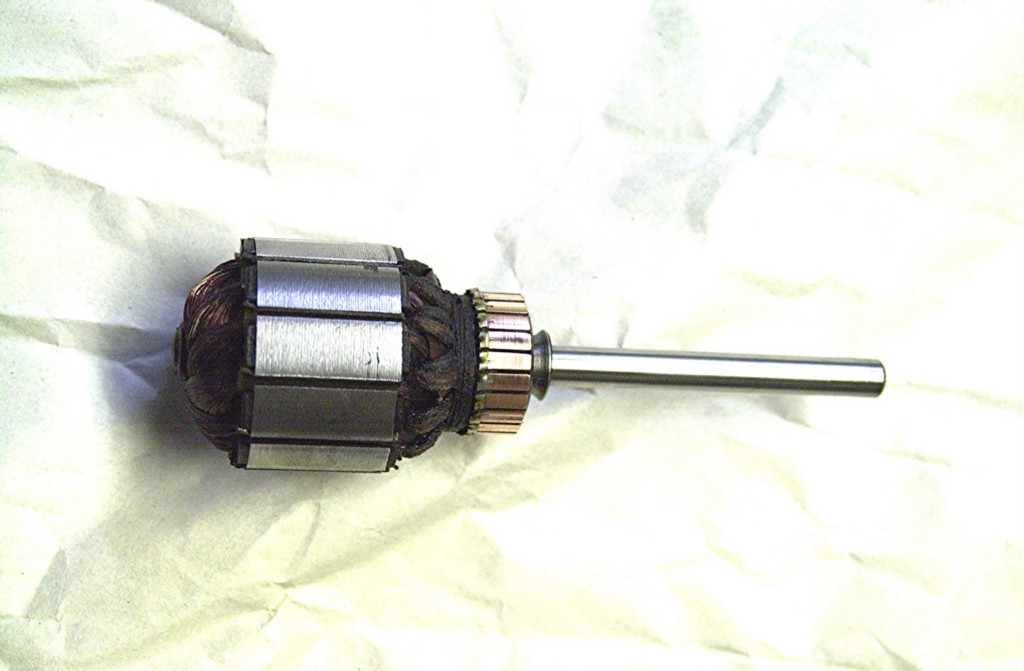

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

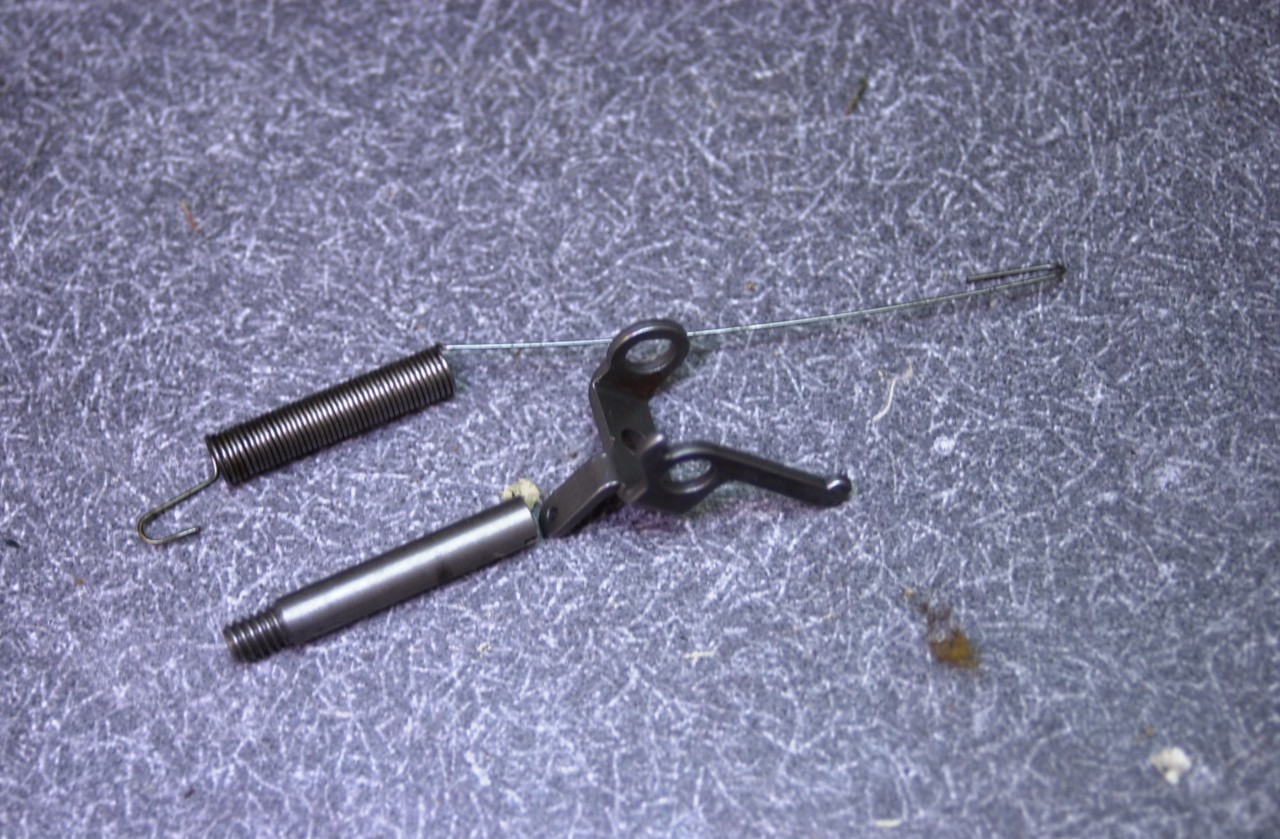

STITCH LENGTH SELECTOR REBUILT

STITCH LENGTH SERVICED

WIRING INSPECTED AND REPLACED

ALL RUBBER AND FELT COMPONENTS REPLACED

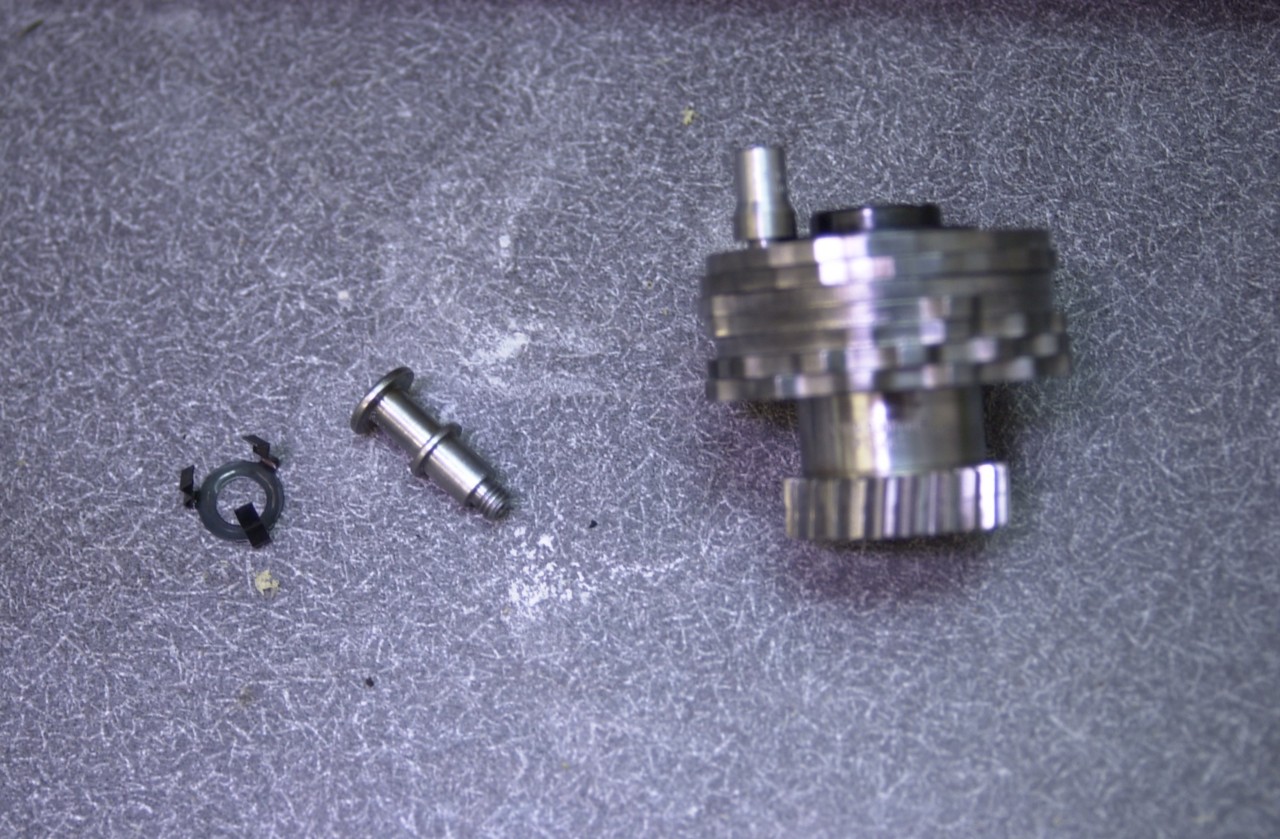

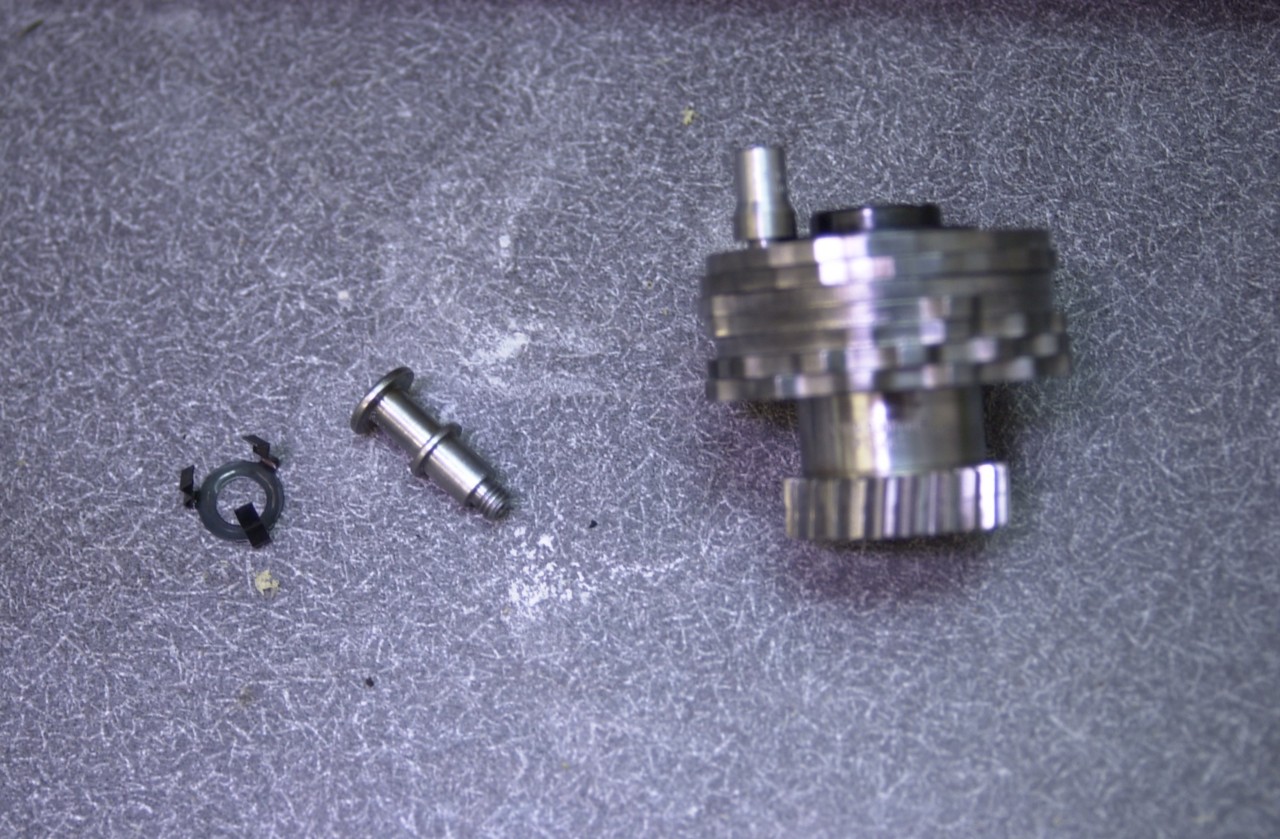

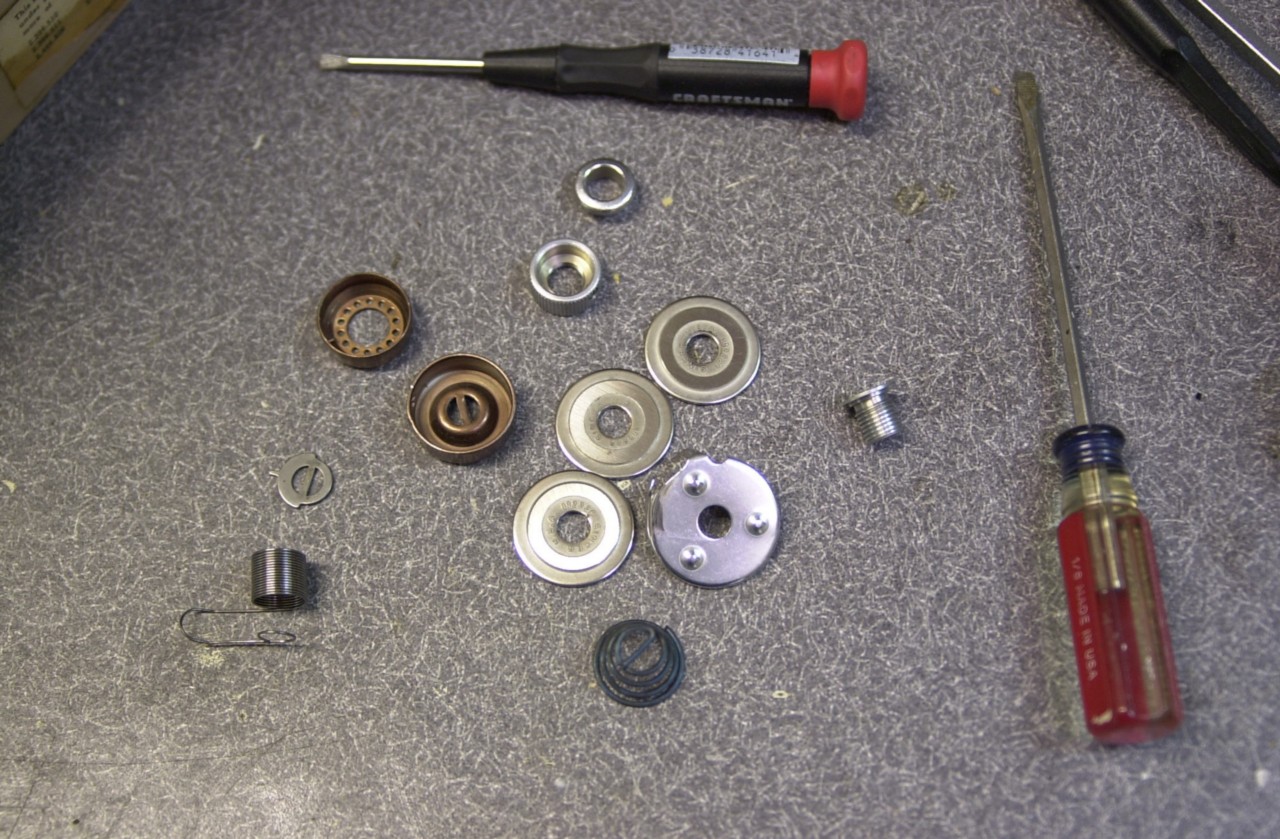

BOBBIN REBUILT

TENSIONER REBUILT

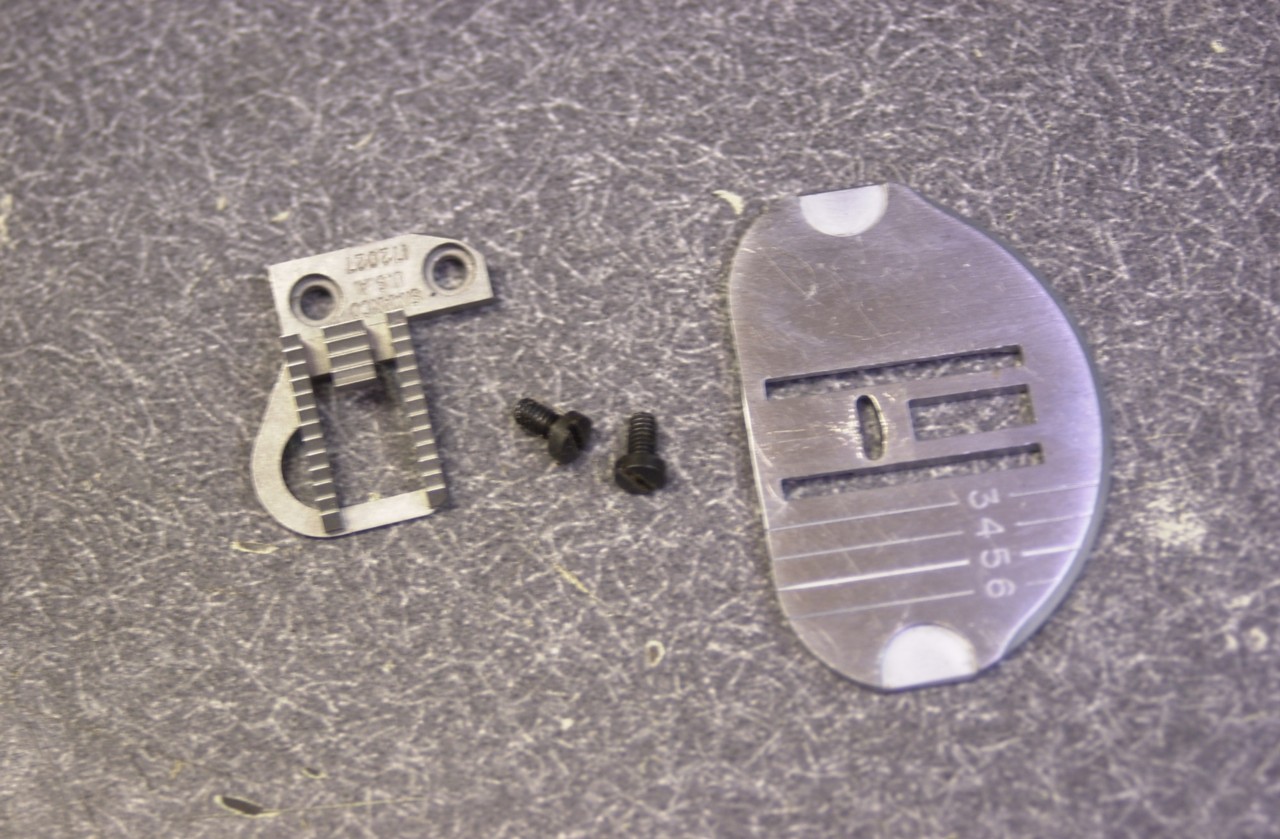

THROAT PLATE ASSEMBLY REBUILT

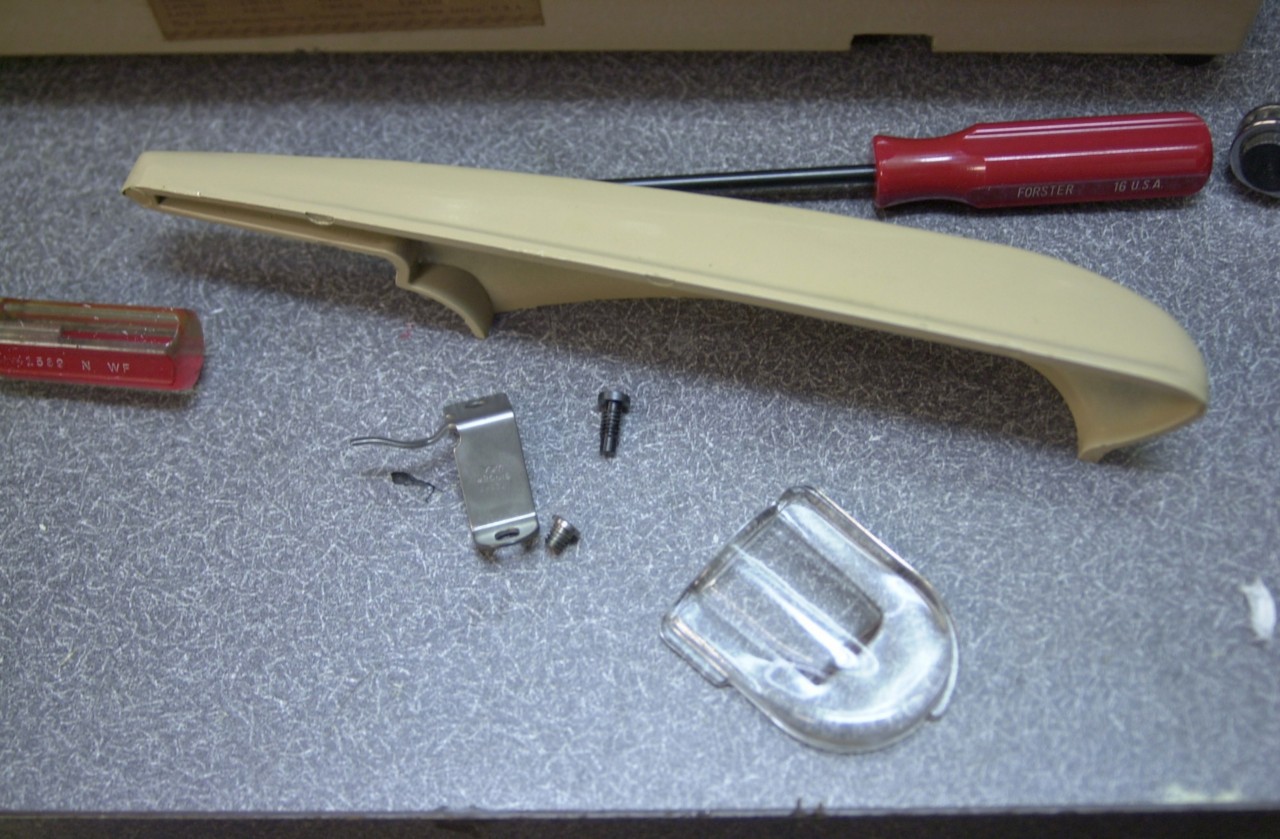

PRESSER FOOT REBUILT

NEEDLE CLAMP CLEANED

FOOT PEDAL REBUILT

.

CAMSTACK SERVICED

CAM SELECTOR REBUILT

BOBBIN WINDER SERVICED

LIGHT ASSEMBLY SERVICED

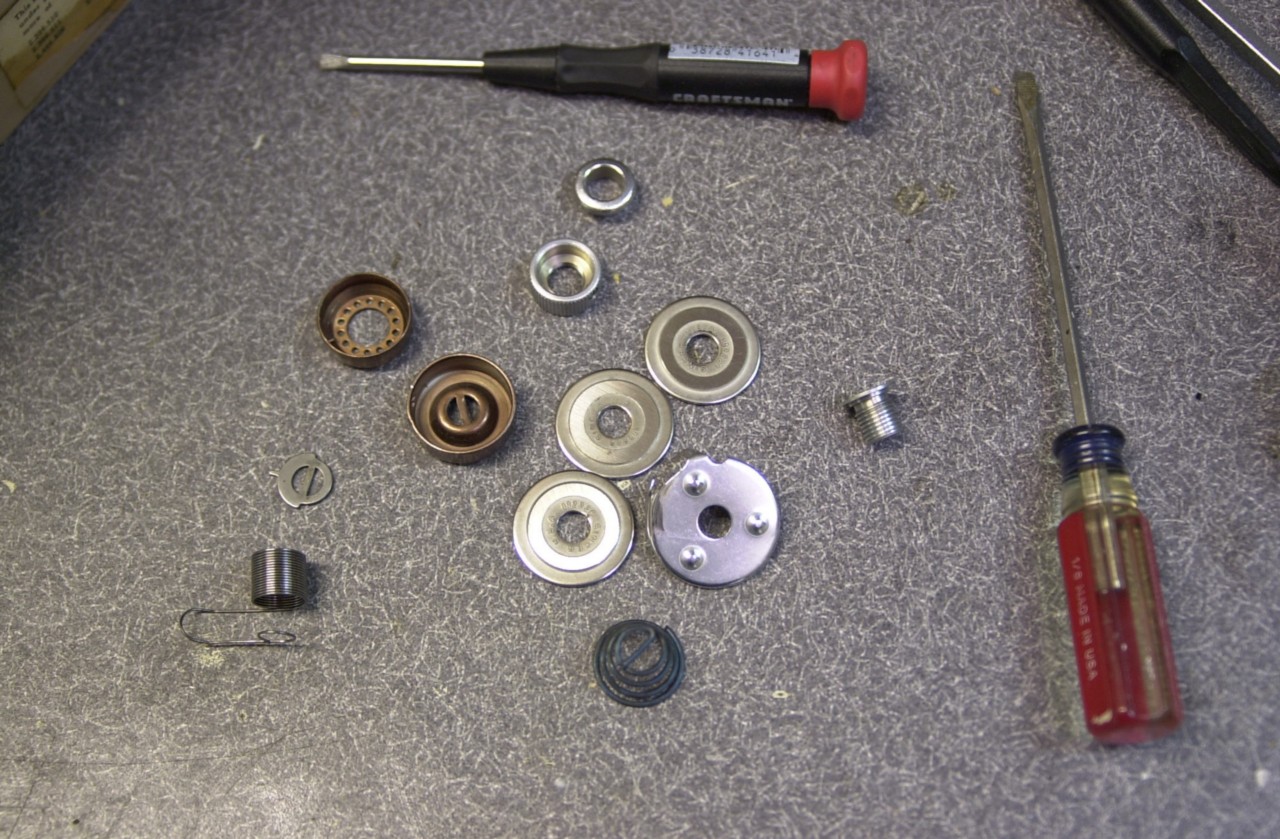

EVEN THE SMALLEST PARTS ARE ULTRASONICALLY CLEANED

LID ASSEMBLY REMOVED POP UP SPOOL PINS AND SPRINGS REPLACED

COMPLETE ADJUSTMENT![]()

LOOK HOW CLEAN THIS MACHINE IS

![]()

IF YOU ARE IN THE MARKET FOR A LIKE NEW 500 THIS IS IT

ACCESSORIES INCLUDED:

6 BOBBINS

9 CAMS INCLUDING

1,2,3,4,5,7,12,19,21

ZIPPER FOOT

ZIG ZAG FOOT

MULTI SLOTTED BINDER FOOT

STRAIGHT STITCH FOOT

HEMMER FOOT

BUTTON FOOT

SPECIAL PURPOSE FOOT .

.

GATHERING FOOT

WALKING FOOT

STRAIGHT STITCH THROAT PLATE

FOOT CONTROL

MANUAL

![]()

FEATURES:

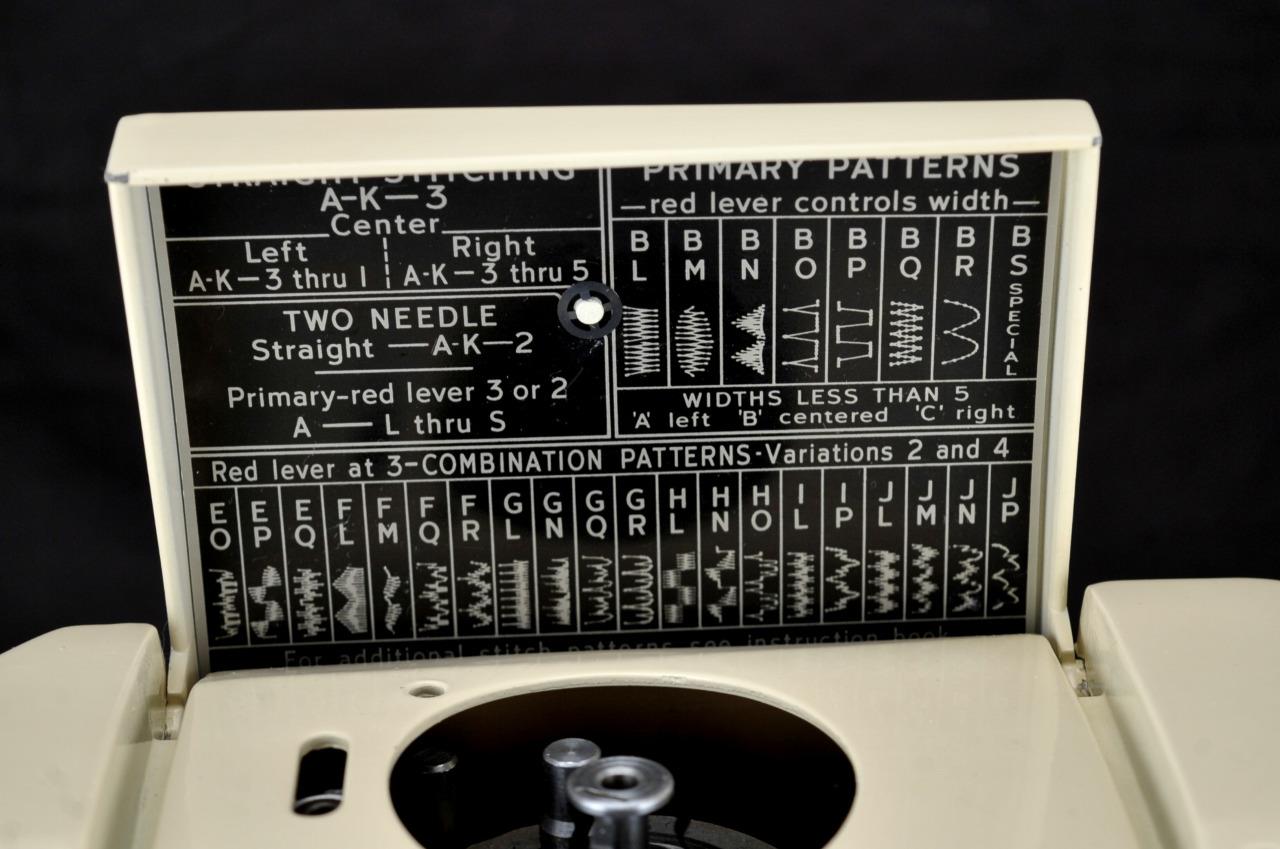

INTERNAL FASHION STITCHES-- THE 500 HAS THE FAMOUS SINGER INTERNAL CAM STACK. OVER 60 STITCH DESIGNS AND VARIATIONS ARE POSSIBLE BY TURNING TWO FRONT SELECTOR KNOBS. IN ADDITION REMOVABLE TOP HAT CAMS ARE AVAILABLE TO CREATE AN ADDITIONAL 60 STITCH VARIATIONS

METAL GEARS-- THE 500 IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 500 IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT![]()

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H)

- Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Built in cam stack with zigzag and decorative stitch capabilities

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs drop

- Light at the front of the machine

- Original foot controller- carbon pile, button style

- Adjustable stitch length and full reverse

- Easy adjustment of needle position

- Adjustable stitch width

- Twin needle and double needle capable

![]()

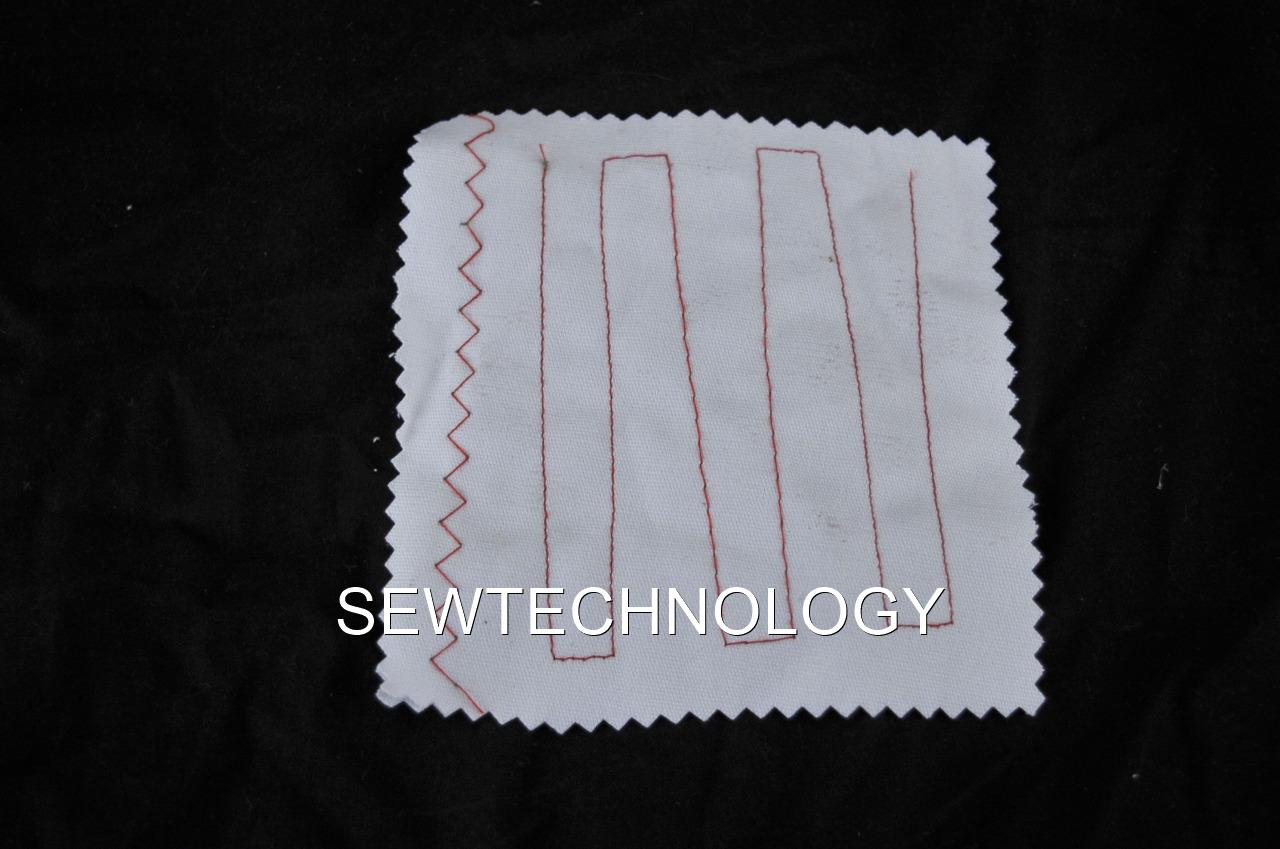

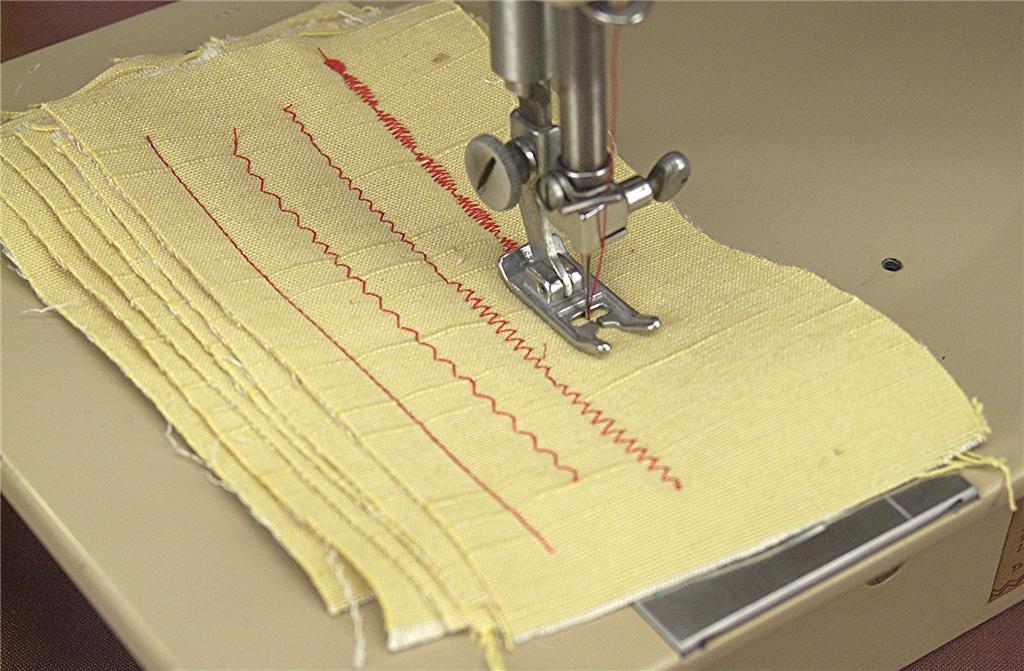

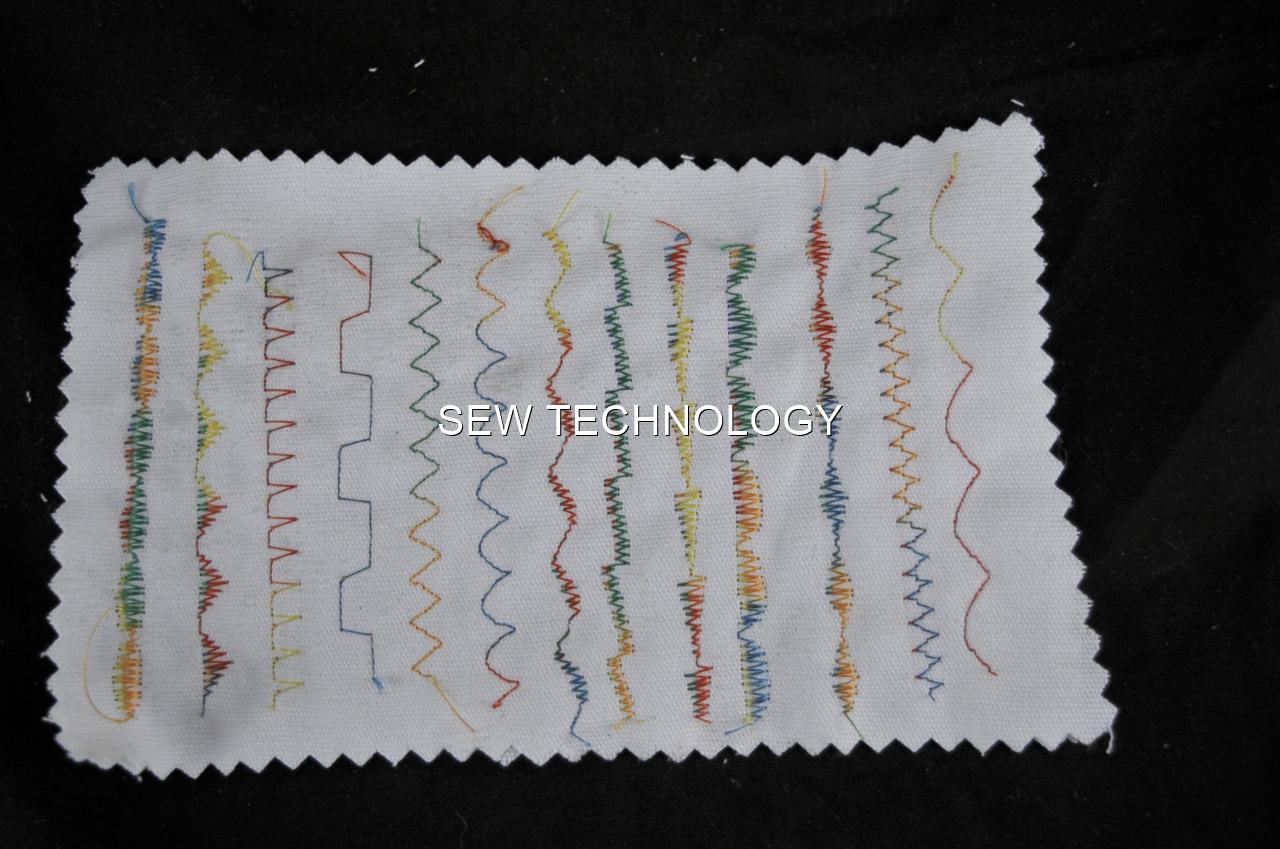

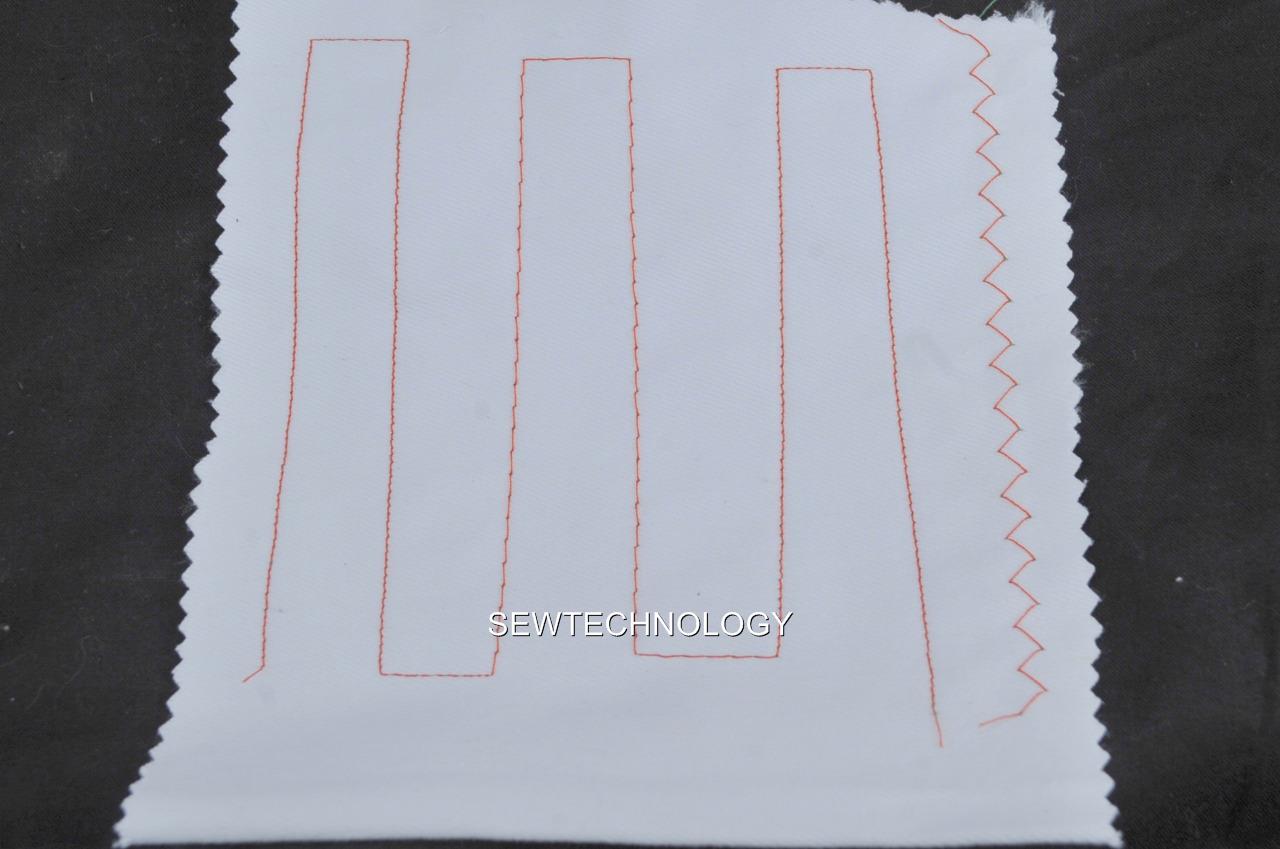

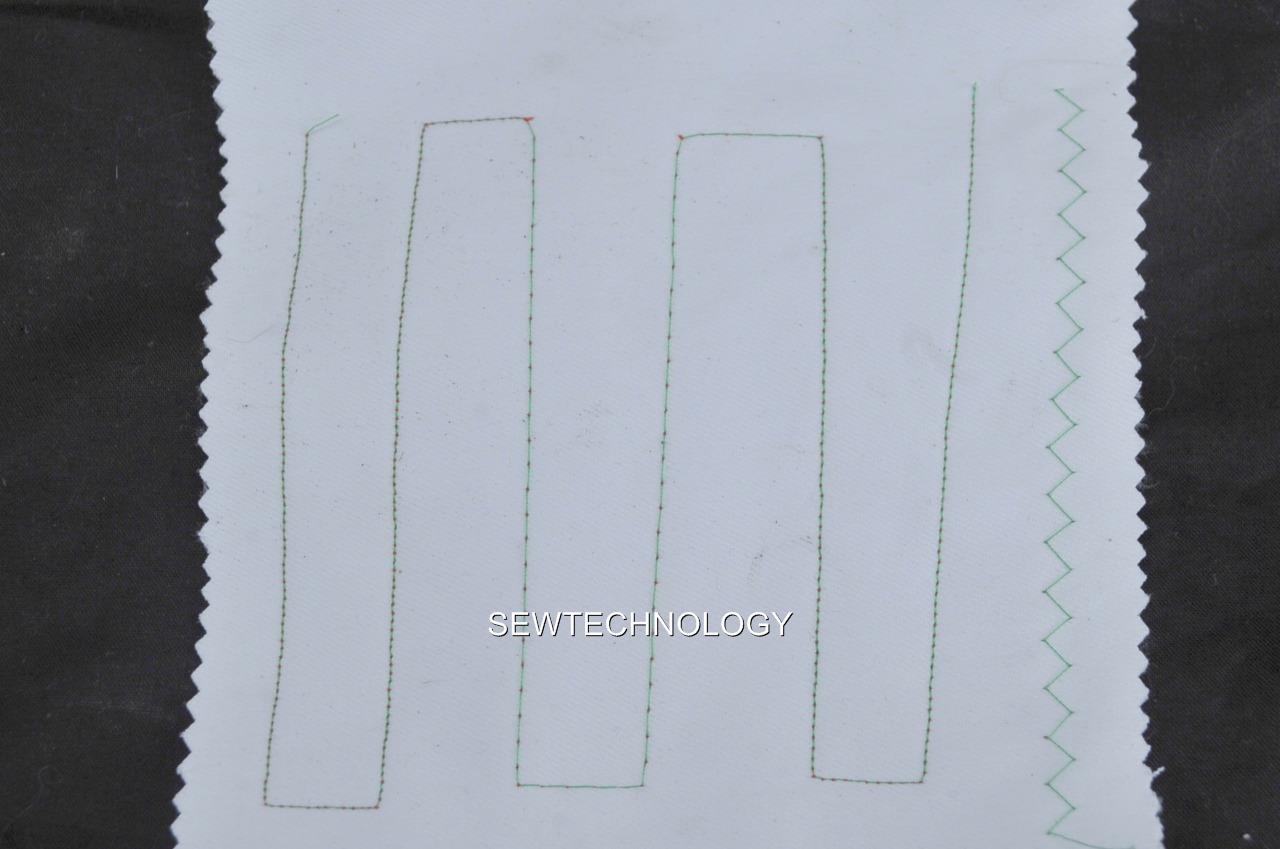

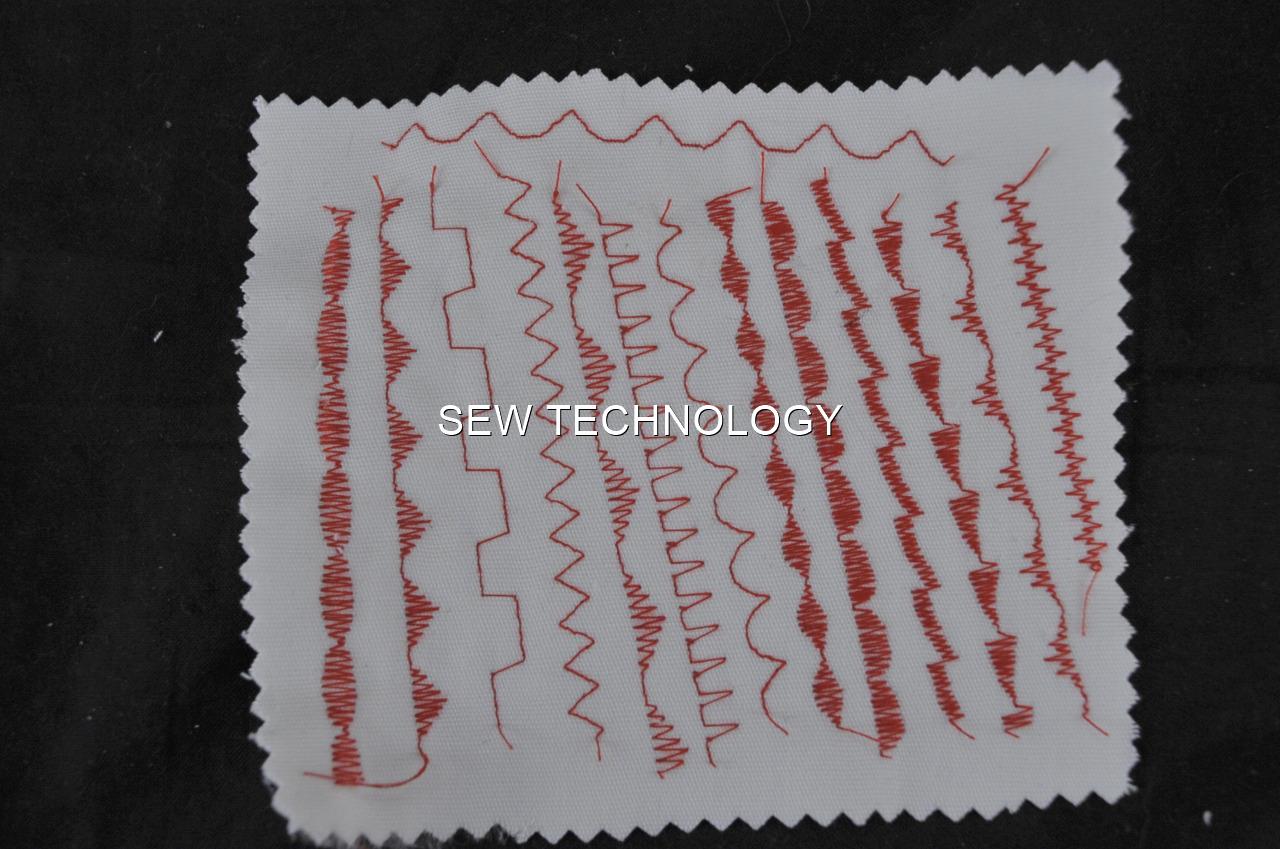

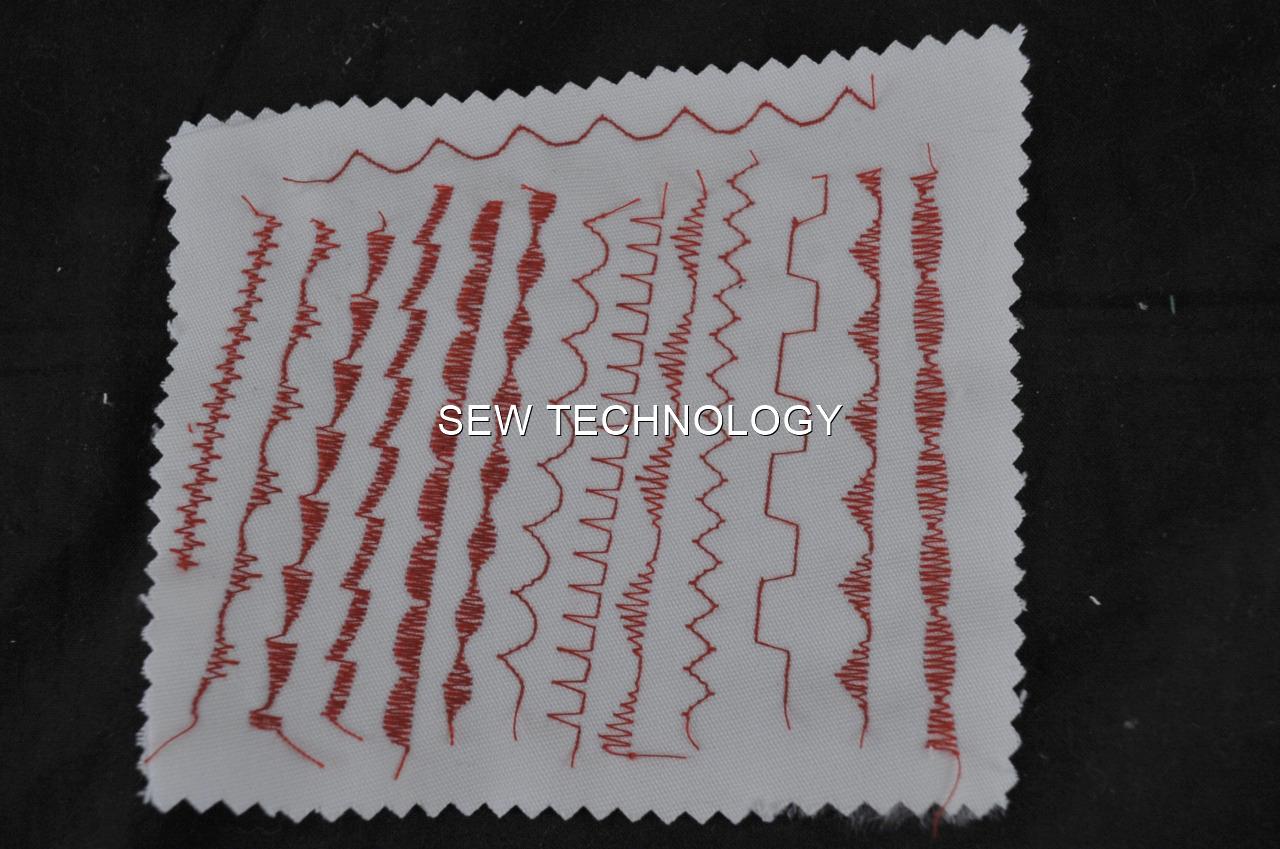

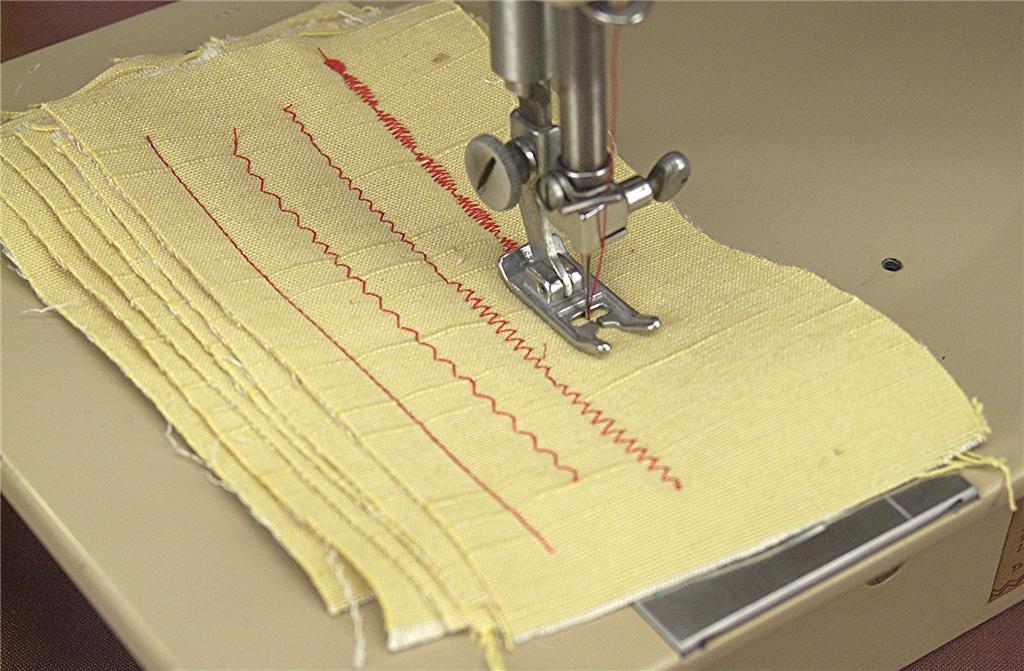

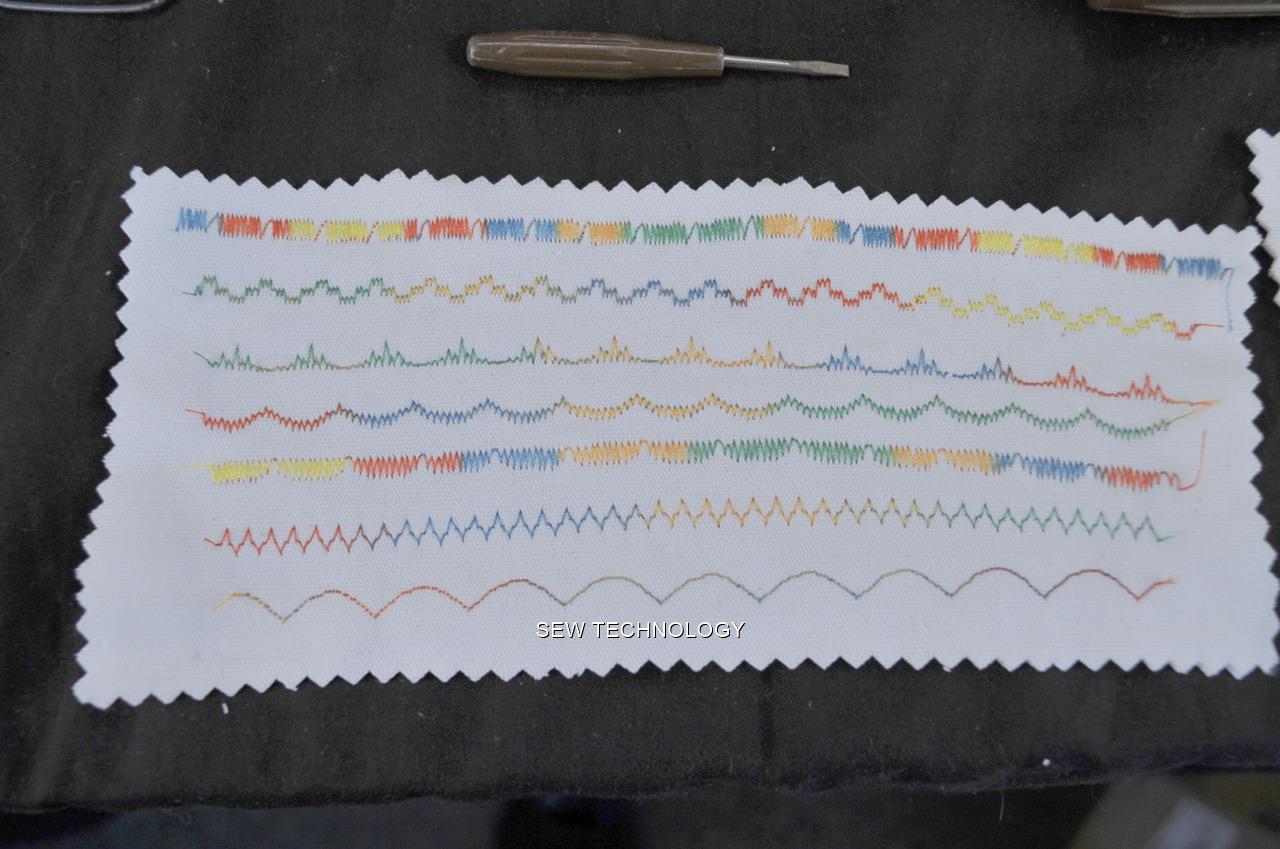

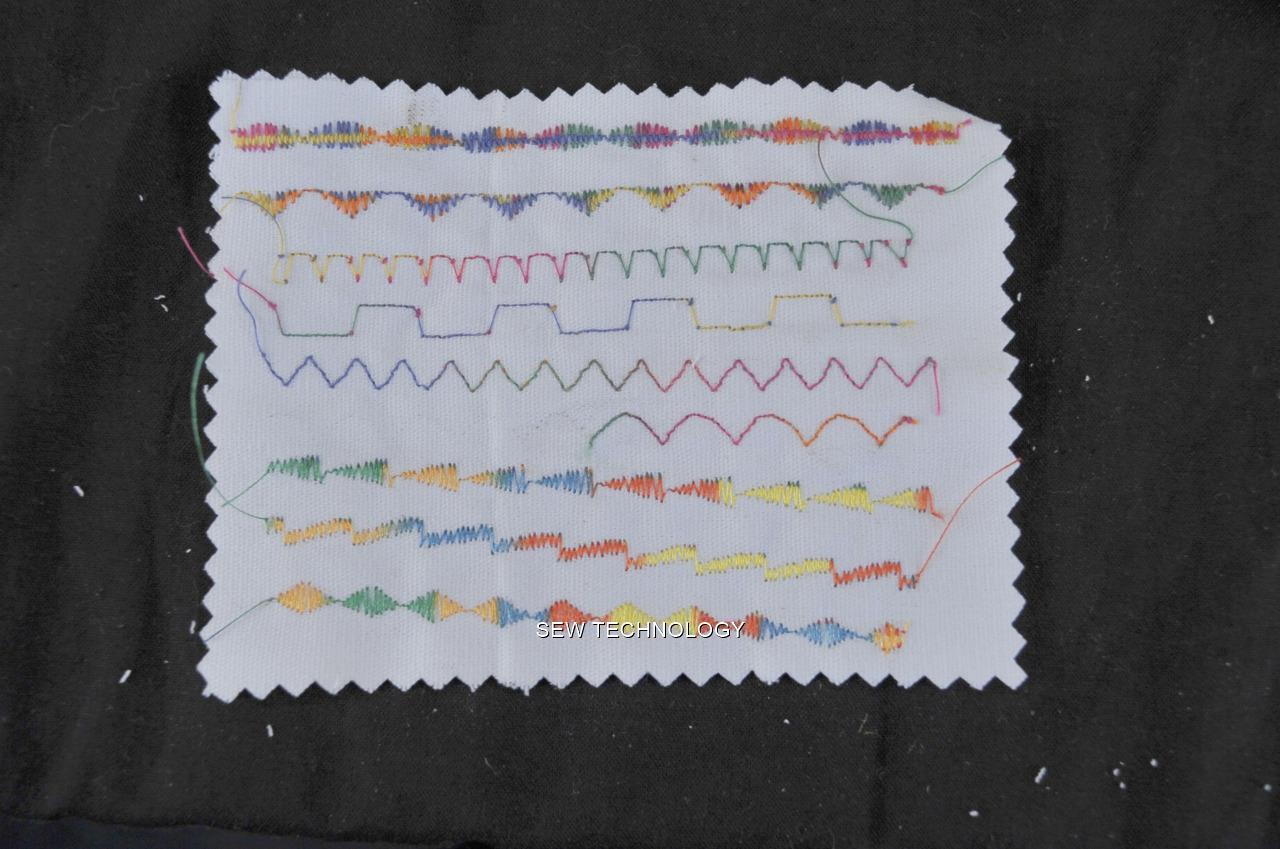

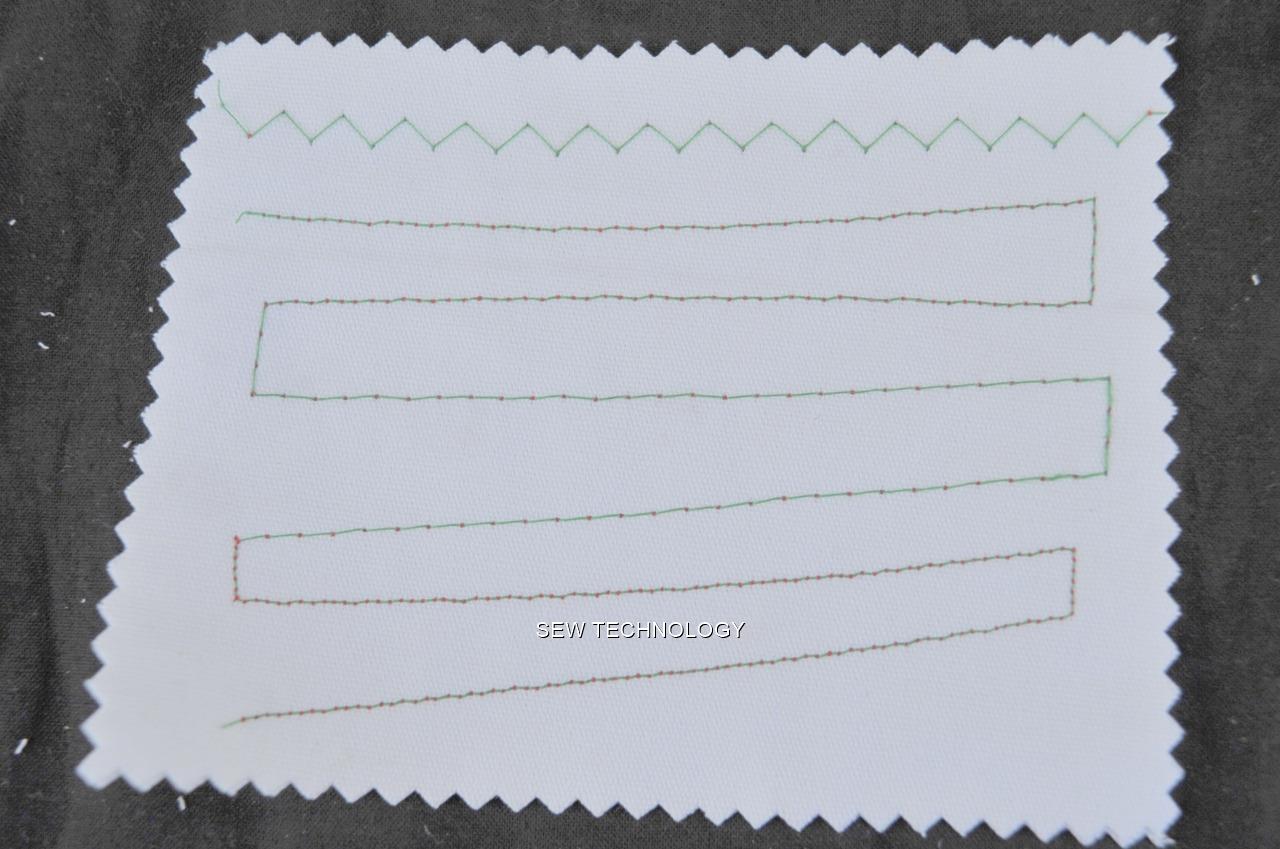

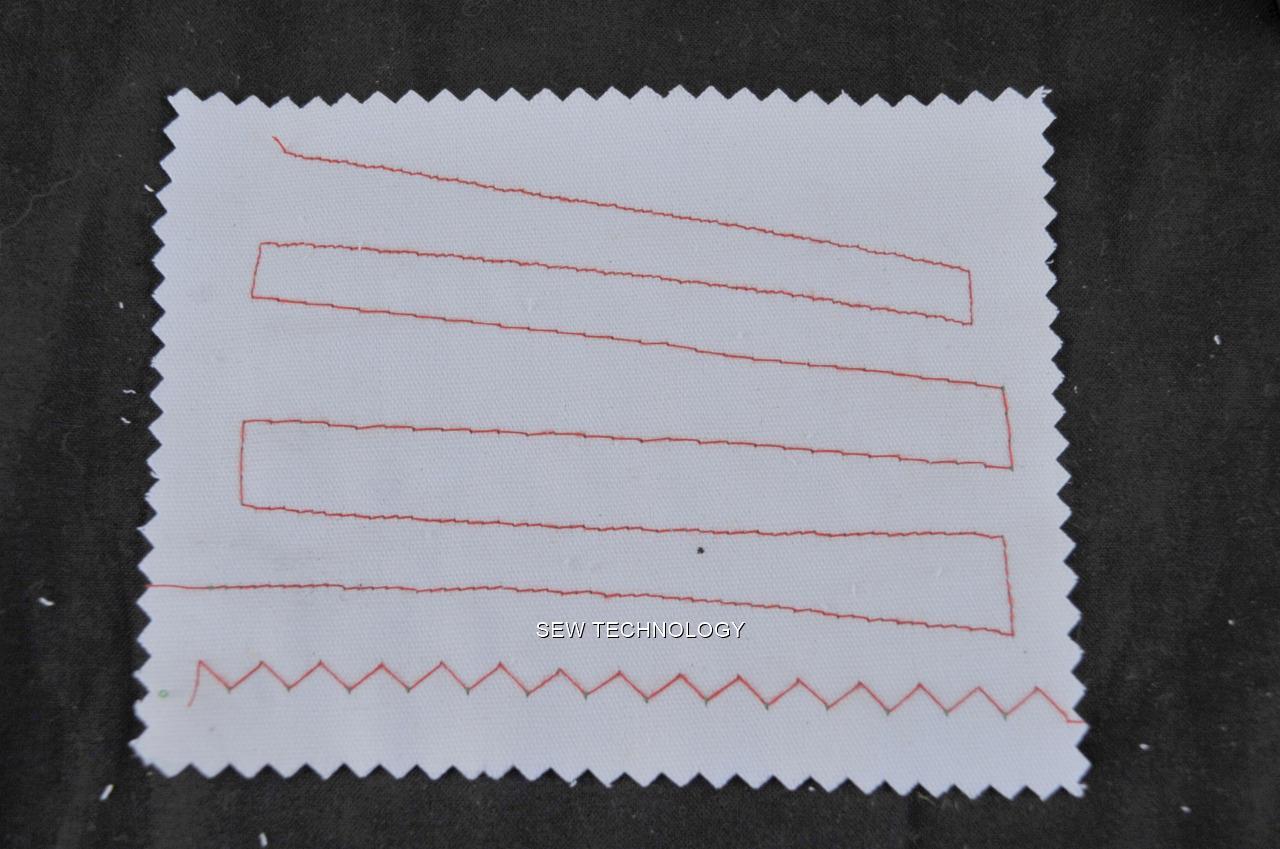

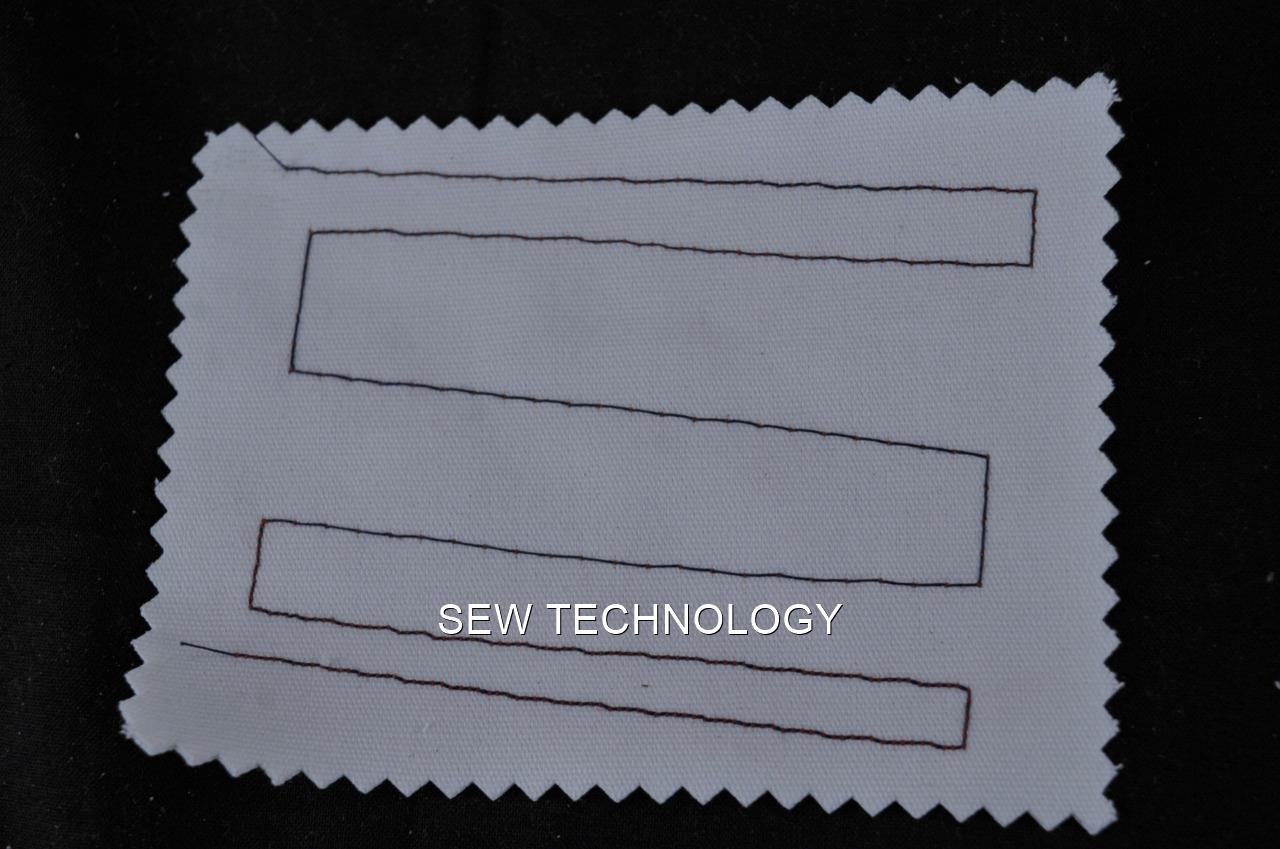

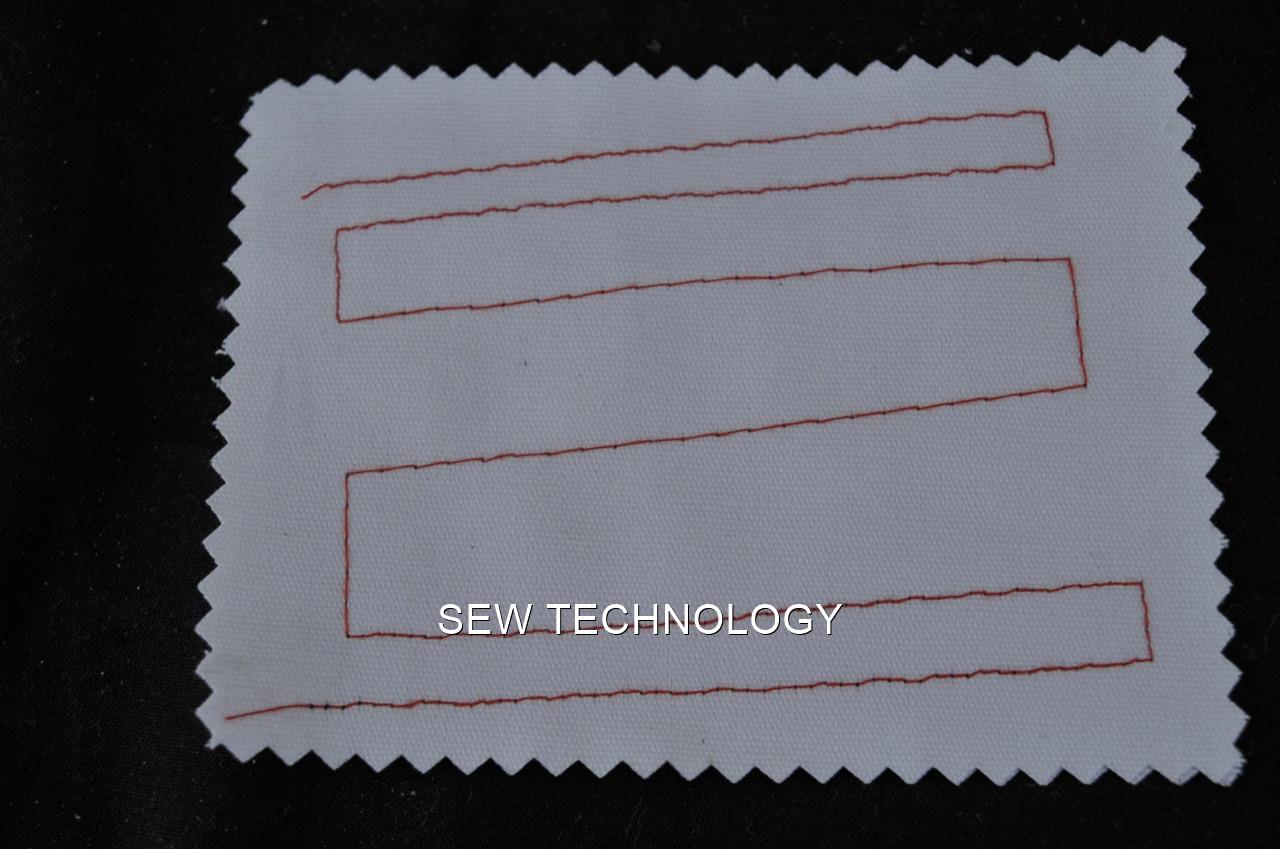

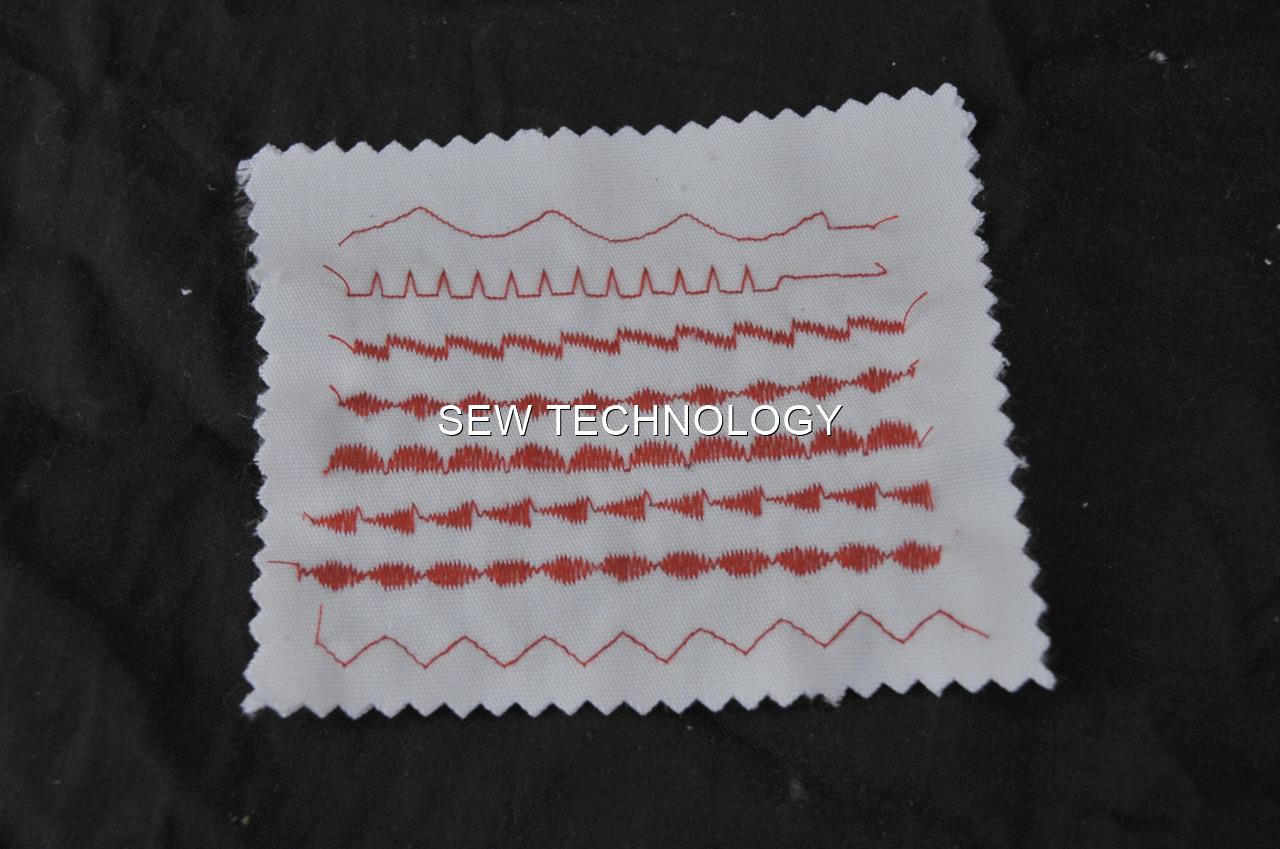

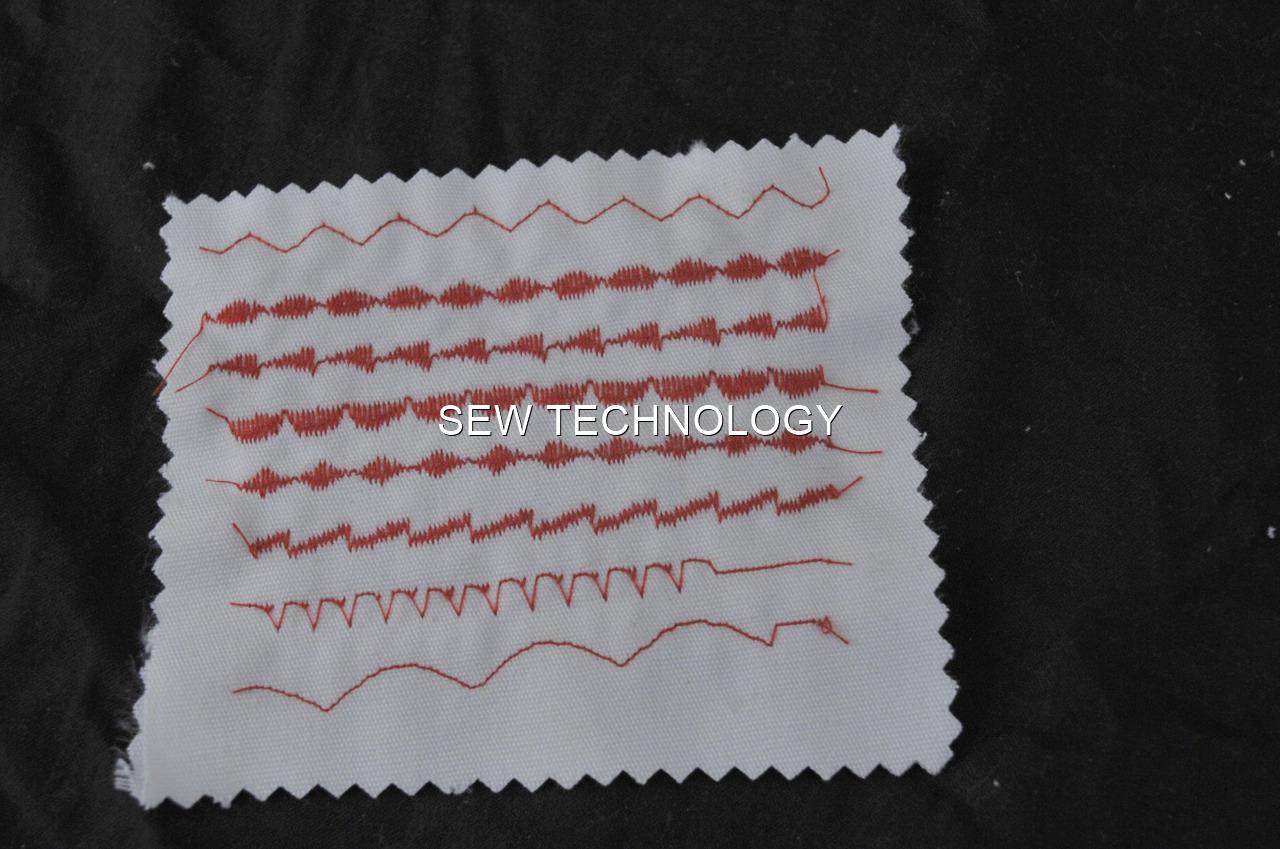

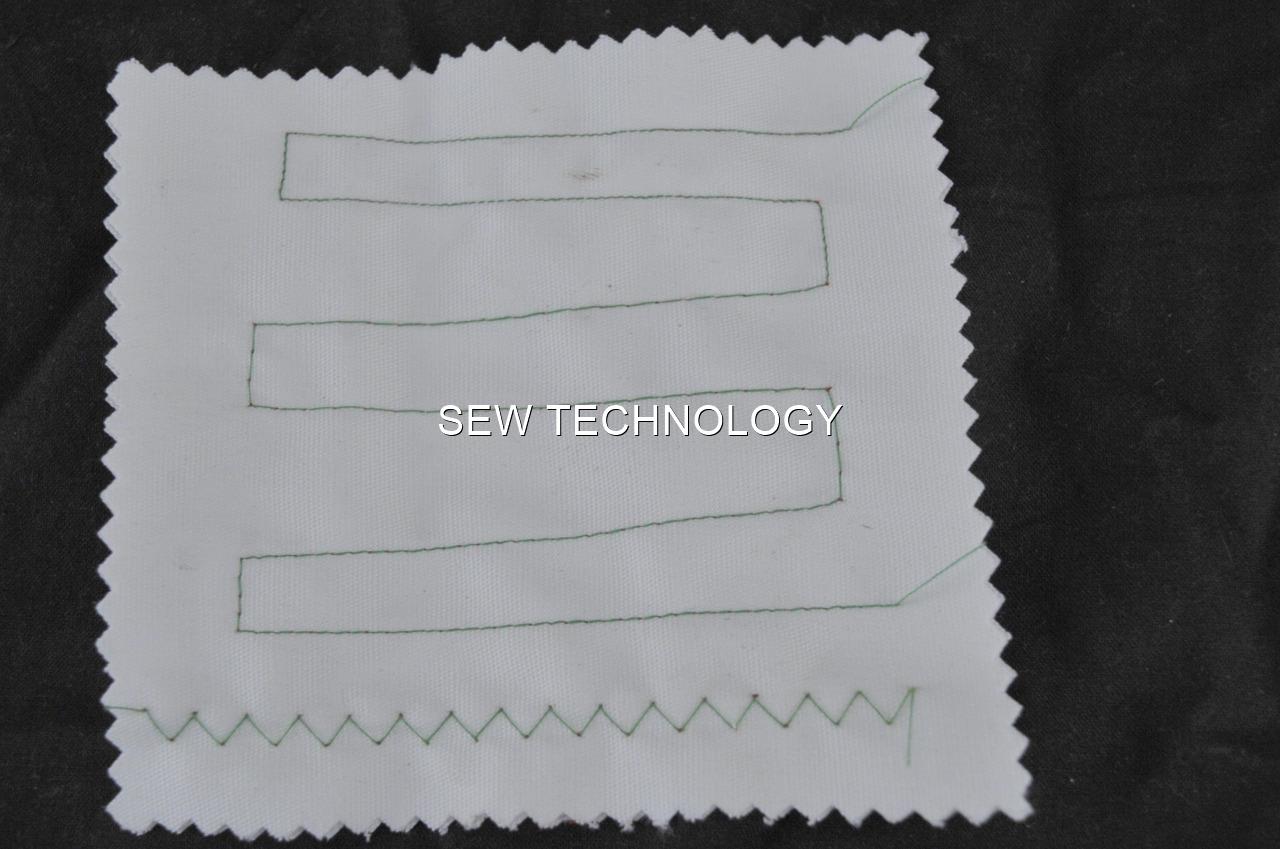

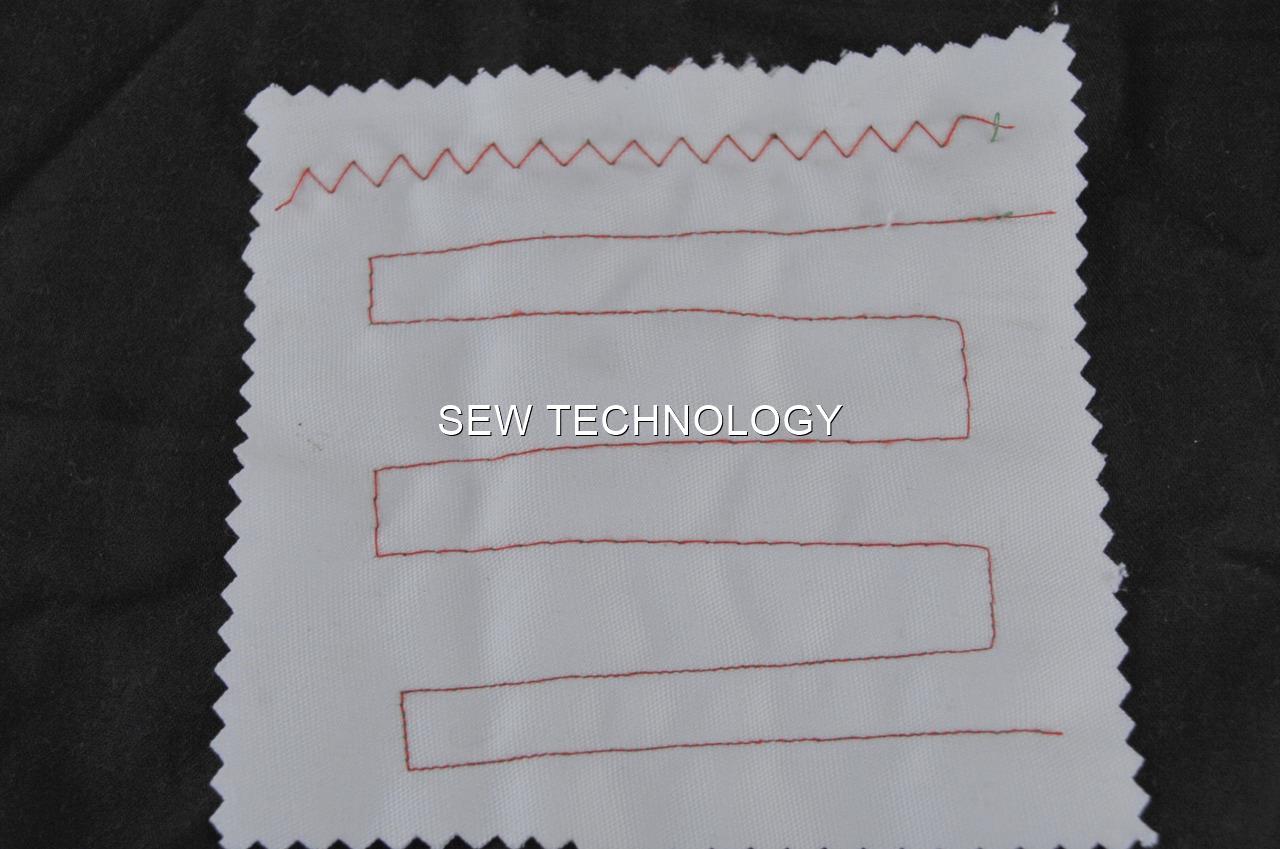

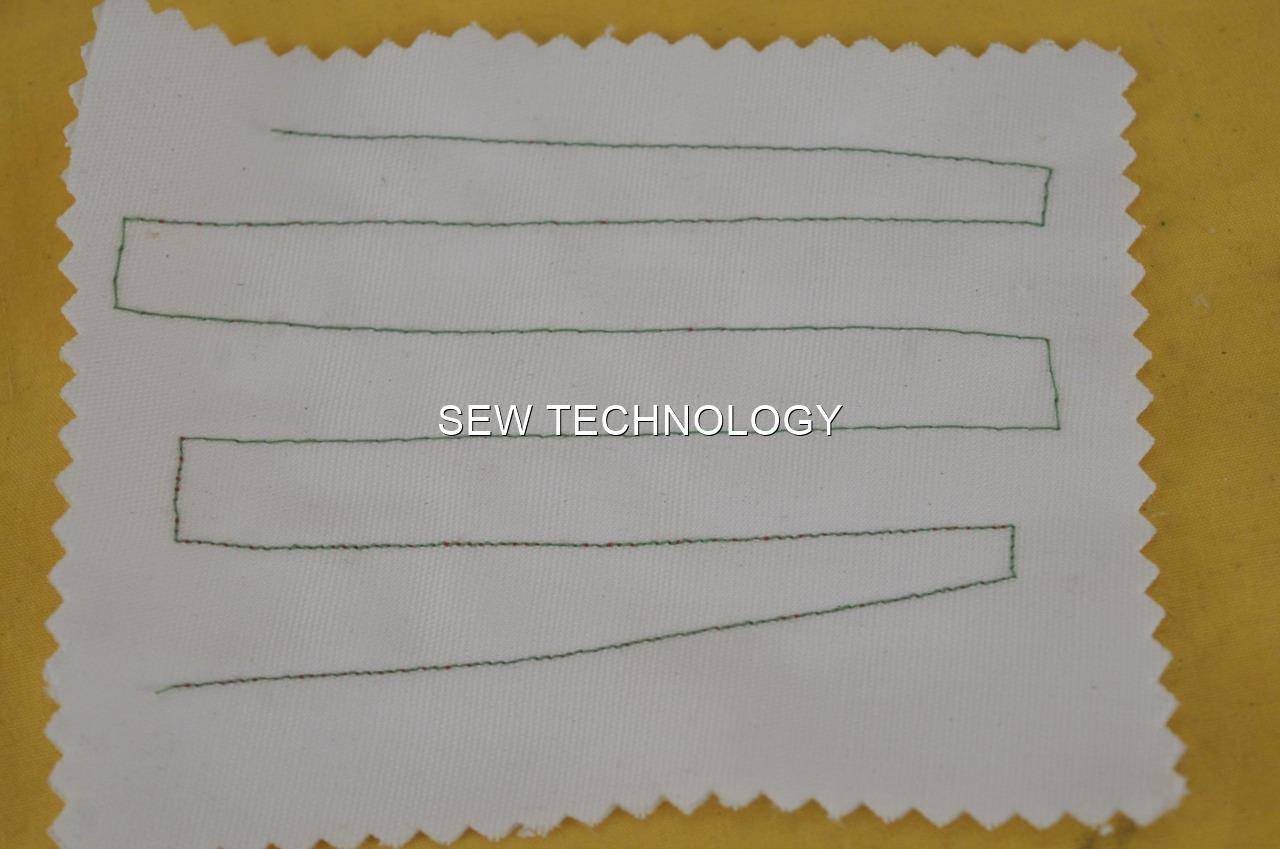

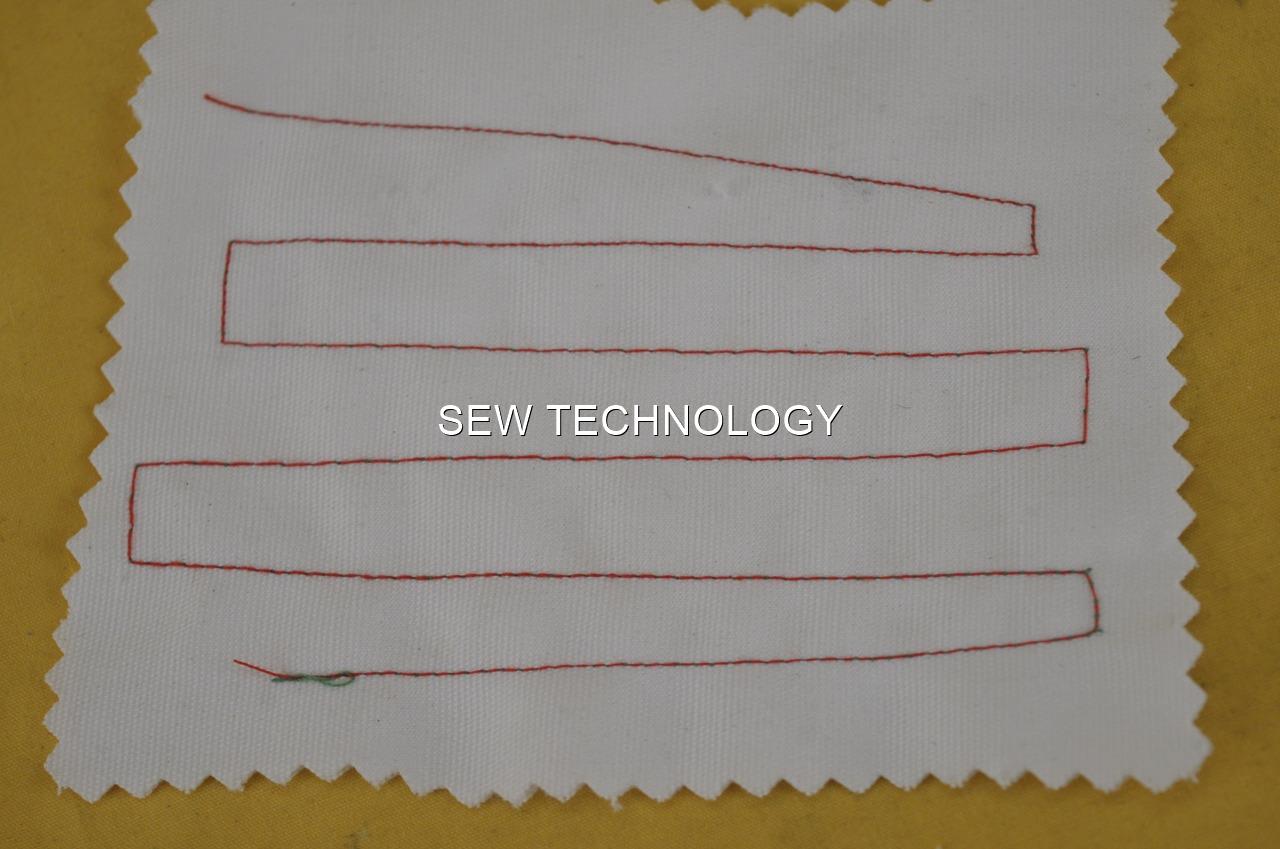

SAMPLE DECORATIVE STITCH VARIATIONS

FRONT AND BACK OF SAMPLE CAMS AND STITCHES

SERIAL# NC559737

.

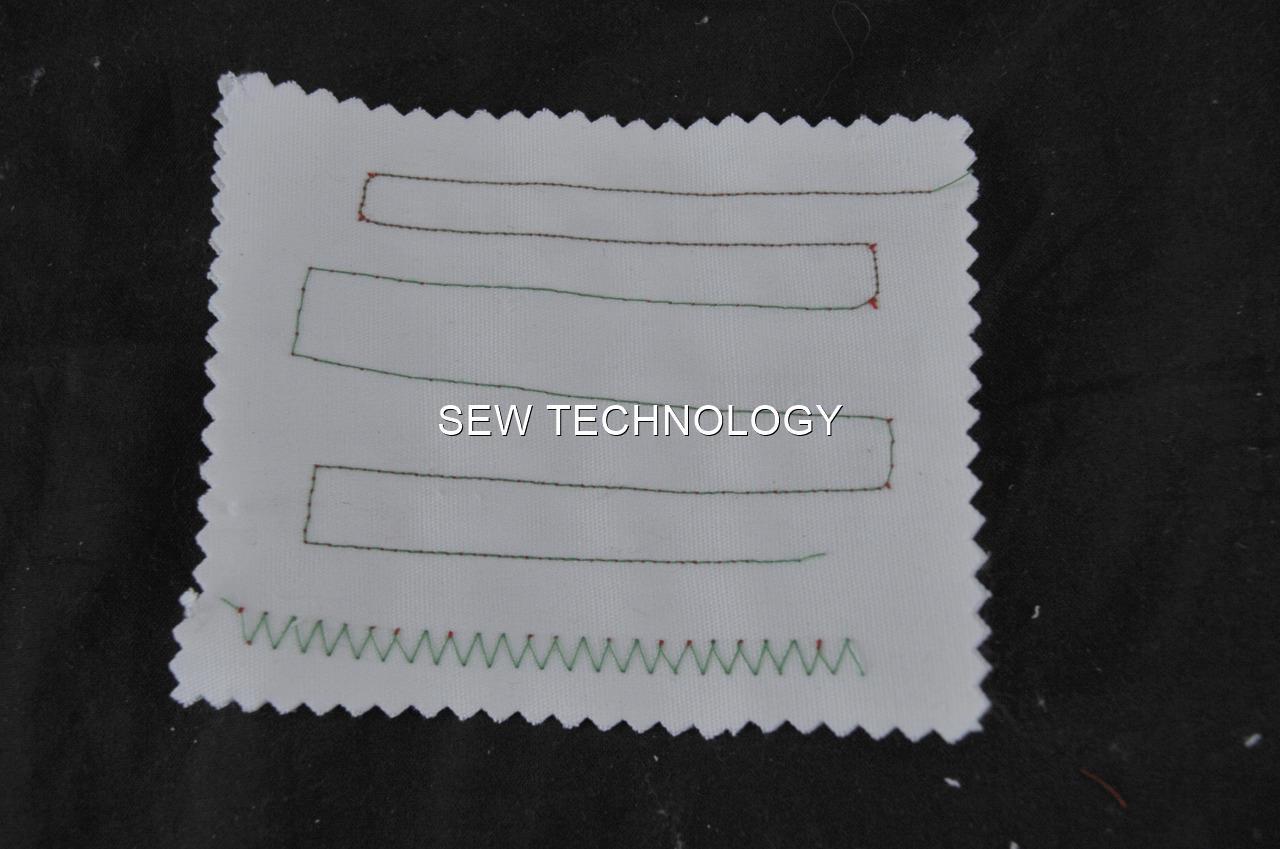

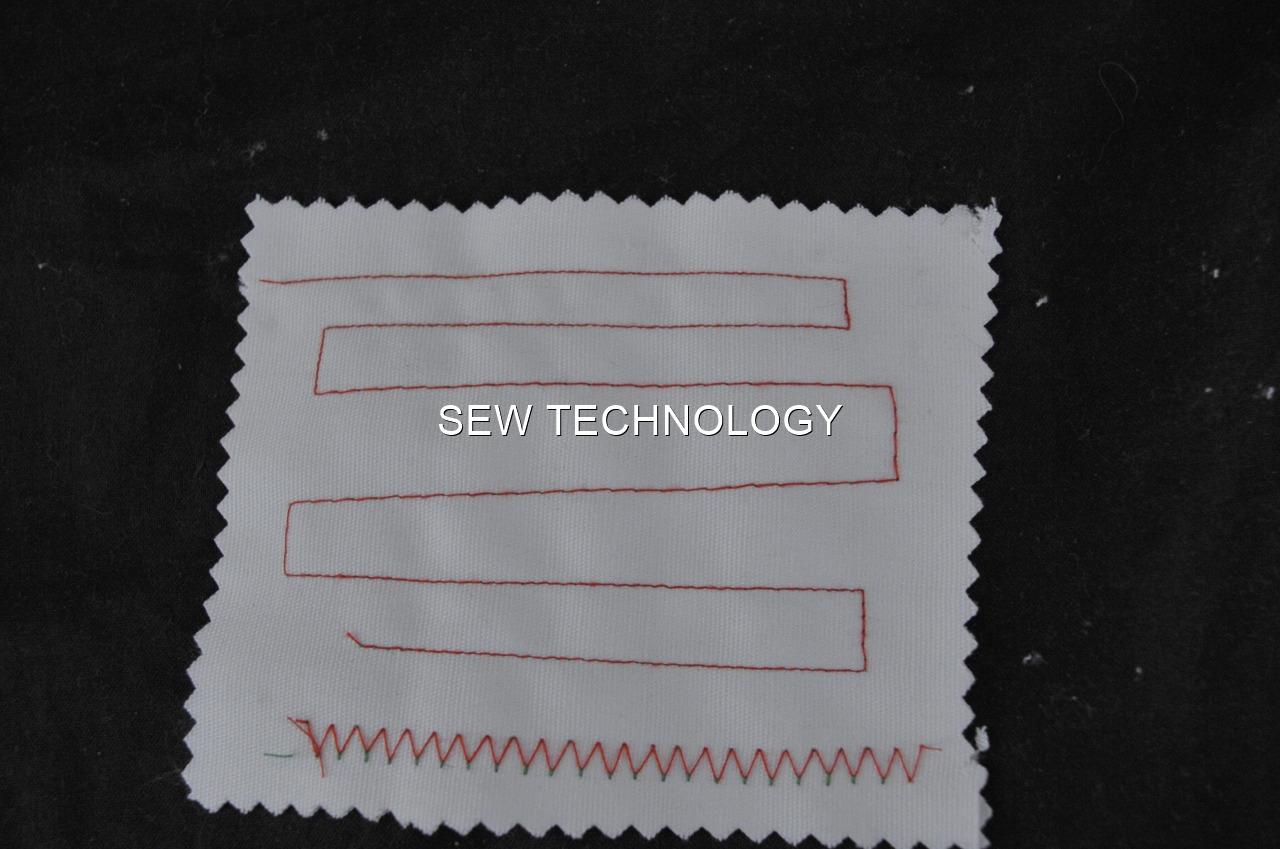

STITCHES SEWN WITH TWO DIFFERENT COLOR THREAD TO SHOW BALANCED STITCH

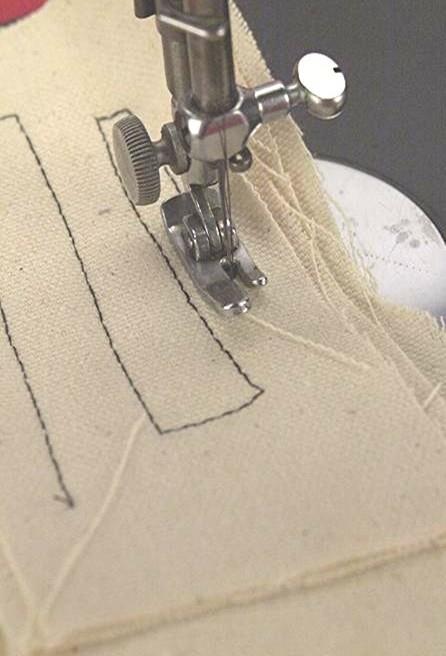

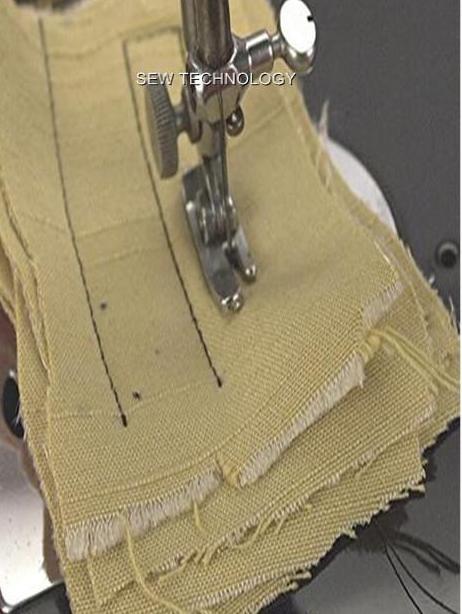

8 LAYERS OF CANVAS

6 LAYERS OF UPHOLSTERY FABRIC

6 LAYERS OF SUEDE

8 LAYERS OF DENIM

6 LAYERS OF DRAPERY MATERIAL

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENTS MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

.

.

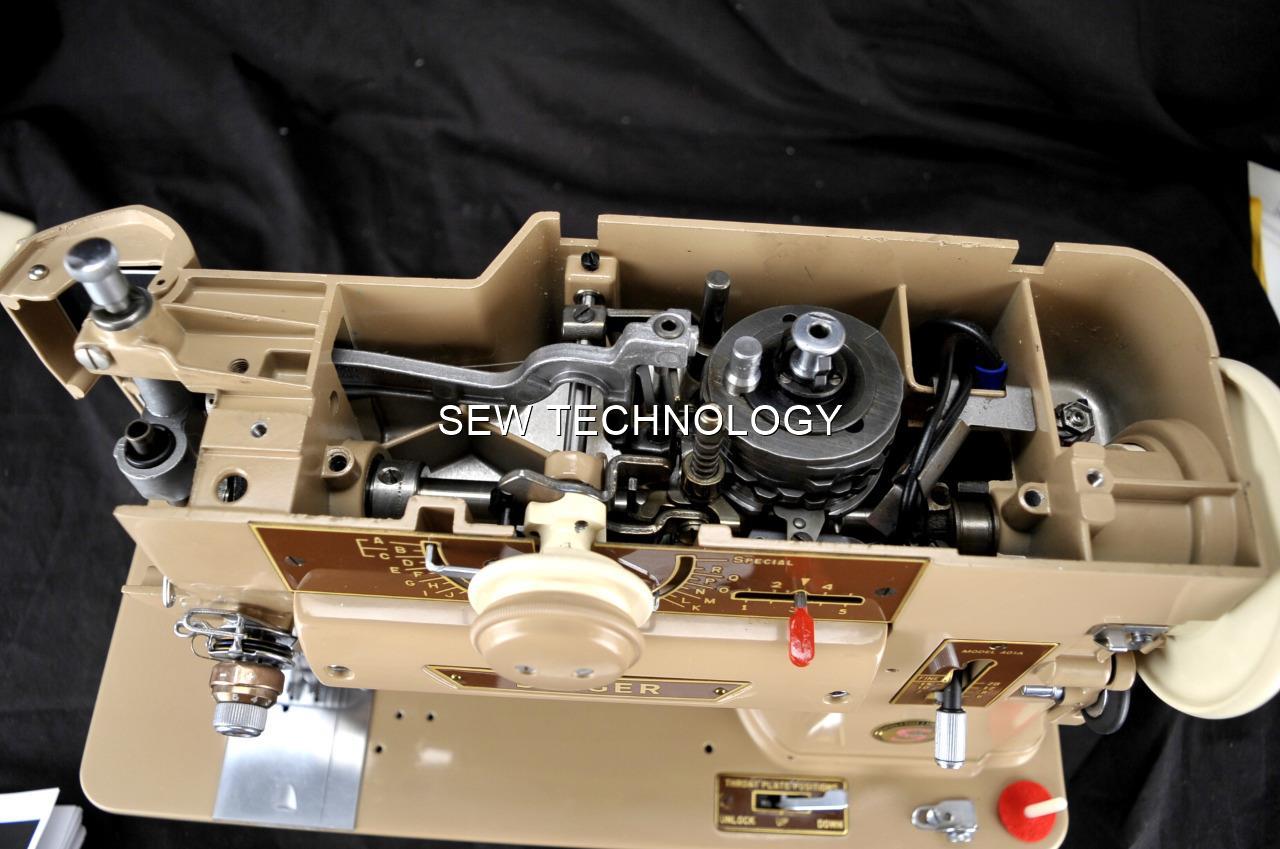

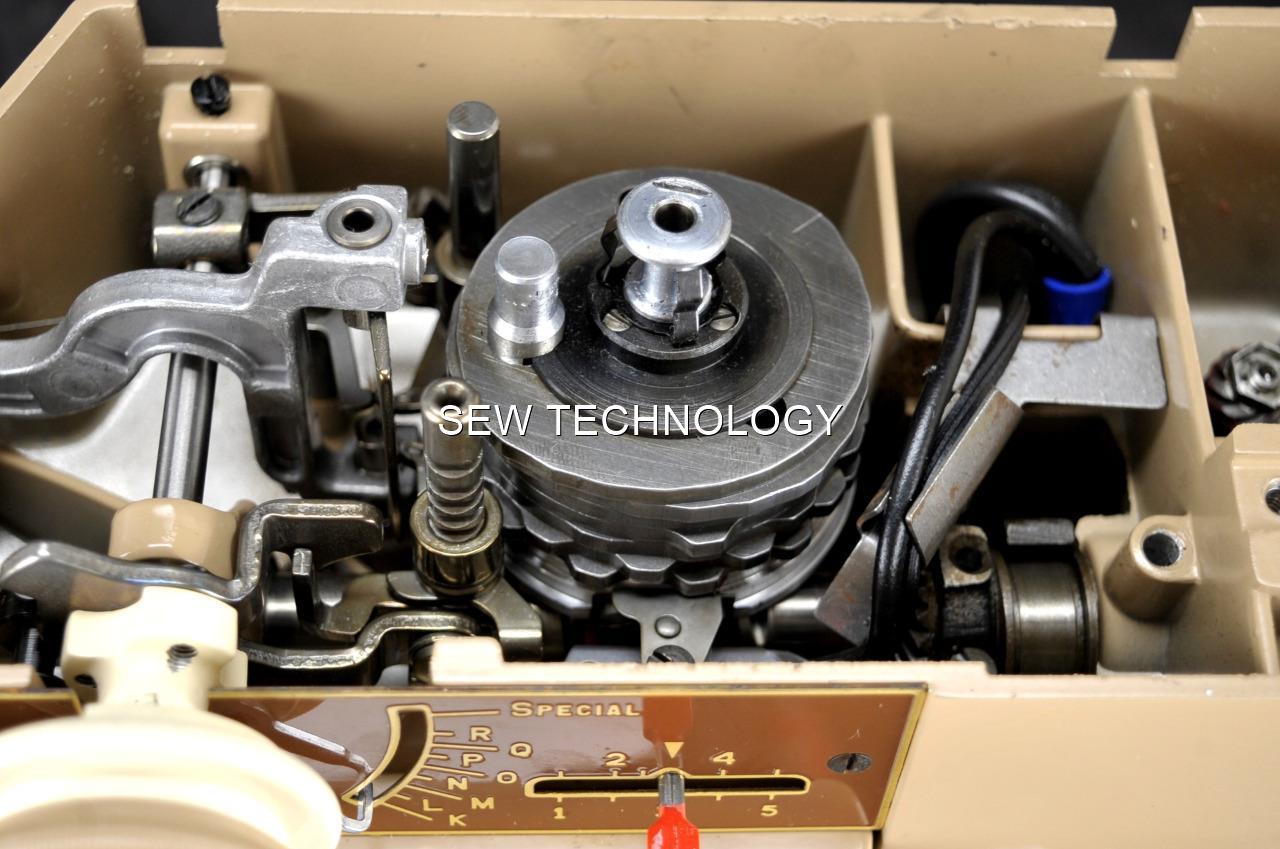

THIS IS A EXCELLENT SINGER 401A SEWING MACHINE

The Singer 401 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary hook. It’s ability to produce many decorative stitches with the built-in cam stack and additional, external cams make it an extremely versatile workhorse. The 401 is considered by many to be the best machine Singer ever built. It is strong, versatile, and does a variety of stitches, and will stand the test of time. The 401 is a fantastic all purpose machines for altering, general, as well as home DECOR applications & various crafts. They have good piercing power when properly maintained and used with the correct needle and settings. They will stand up to heavy use and some abuse and still purr along nicely with only minor care. These machines were NOT cheap when when they were first produced. In 2010 dollars, a Singer 401 would run you about $2,800. These superbly crafted vintage machines will will long outlast any new machine on the market.

When this machine was produced, it cost about $350. Do you know what that would convert to in today's dollars? It would cost $0.00...you know why...you cant get an all metal gear driven machine, at any cost today

The 401A Slant-O-Matic feature moves the needle over 1-inch closer to the operator. The average bed is 7 inches wide and the needles are usually centered. On the Slant-O-Matic, the needle is less than 2-1/2 inches from the edge of the bed.

The machine features a all metal gear driven slant needle, zig zag design with internal design disks.

THIS 401 IS IN GREAT CONDITION... THIS MACHINE IS IN EXCELLENT MECHANICAL AND COSMETIC CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE. .

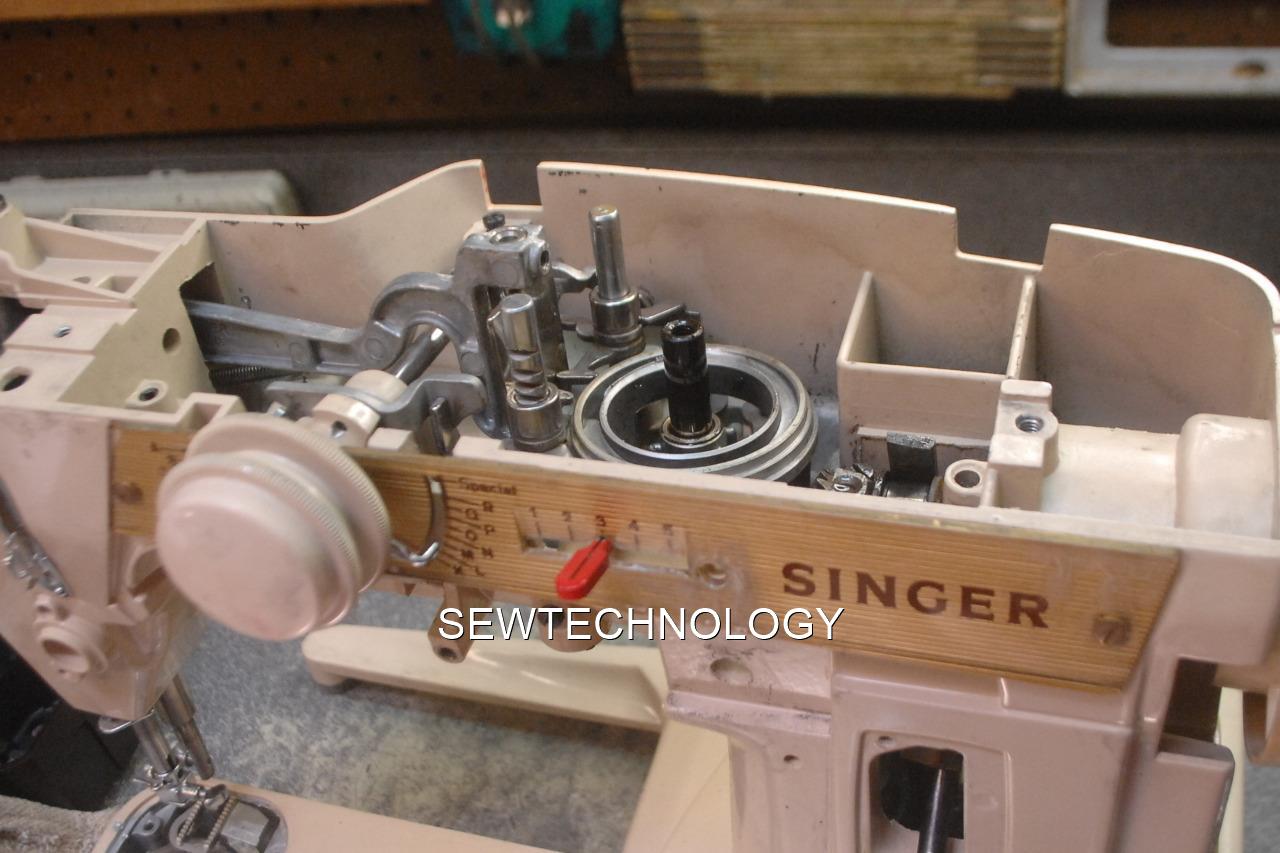

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

![]()

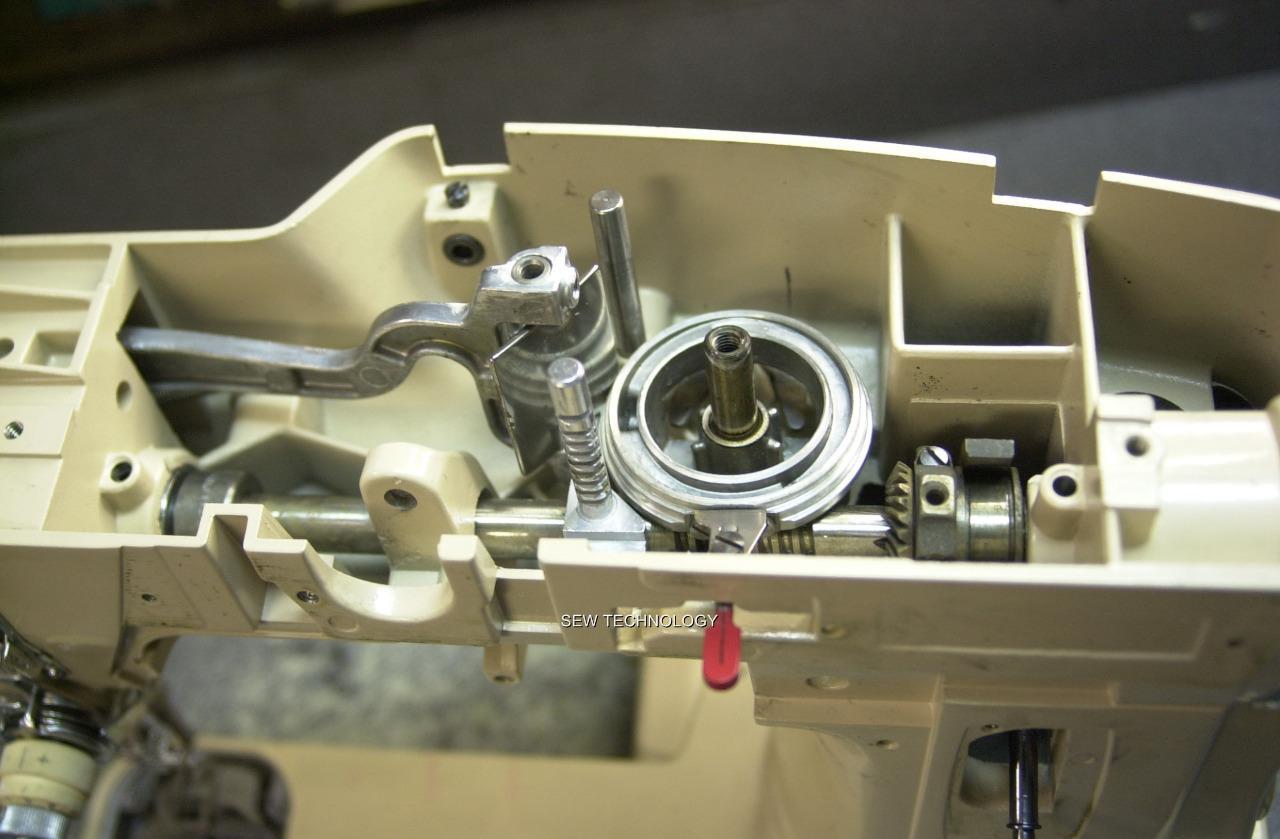

COMPLETELY SERVICED

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

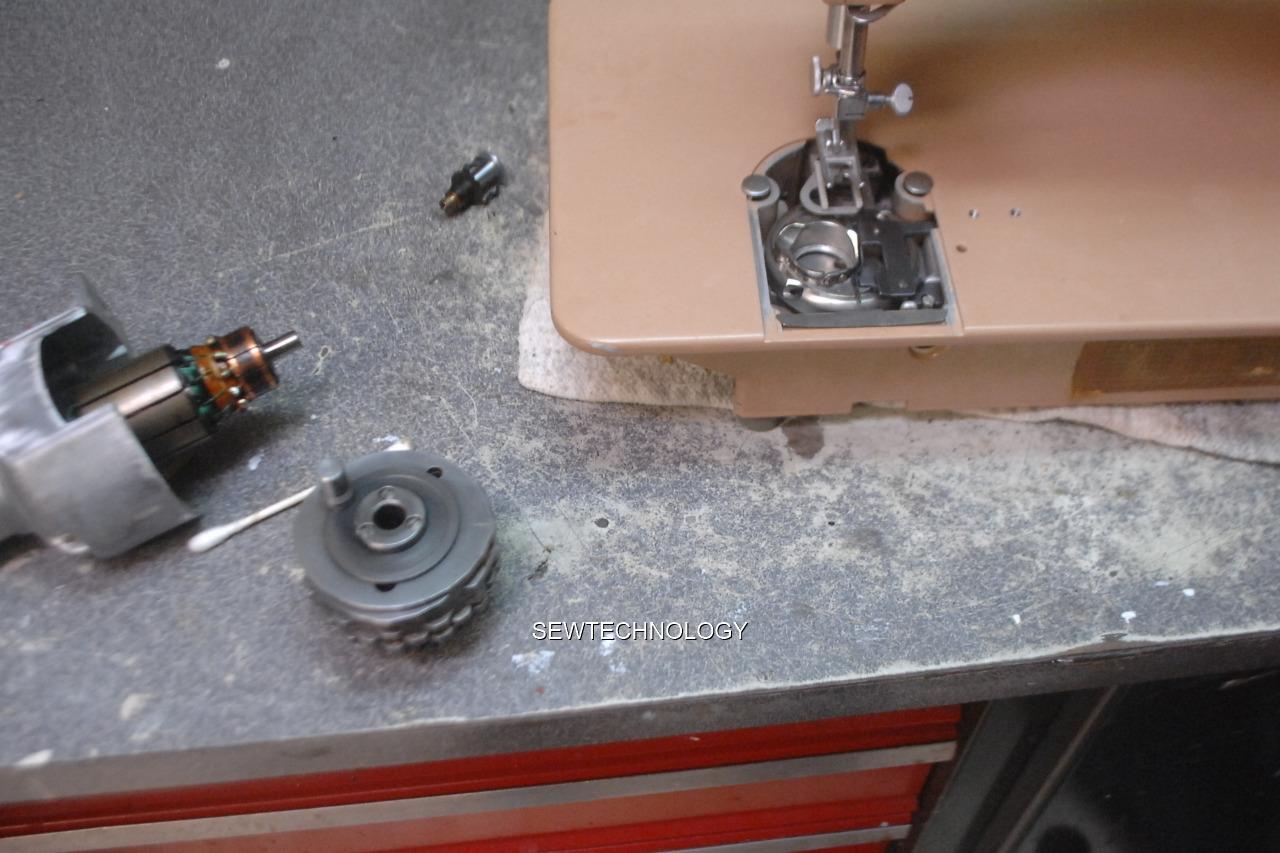

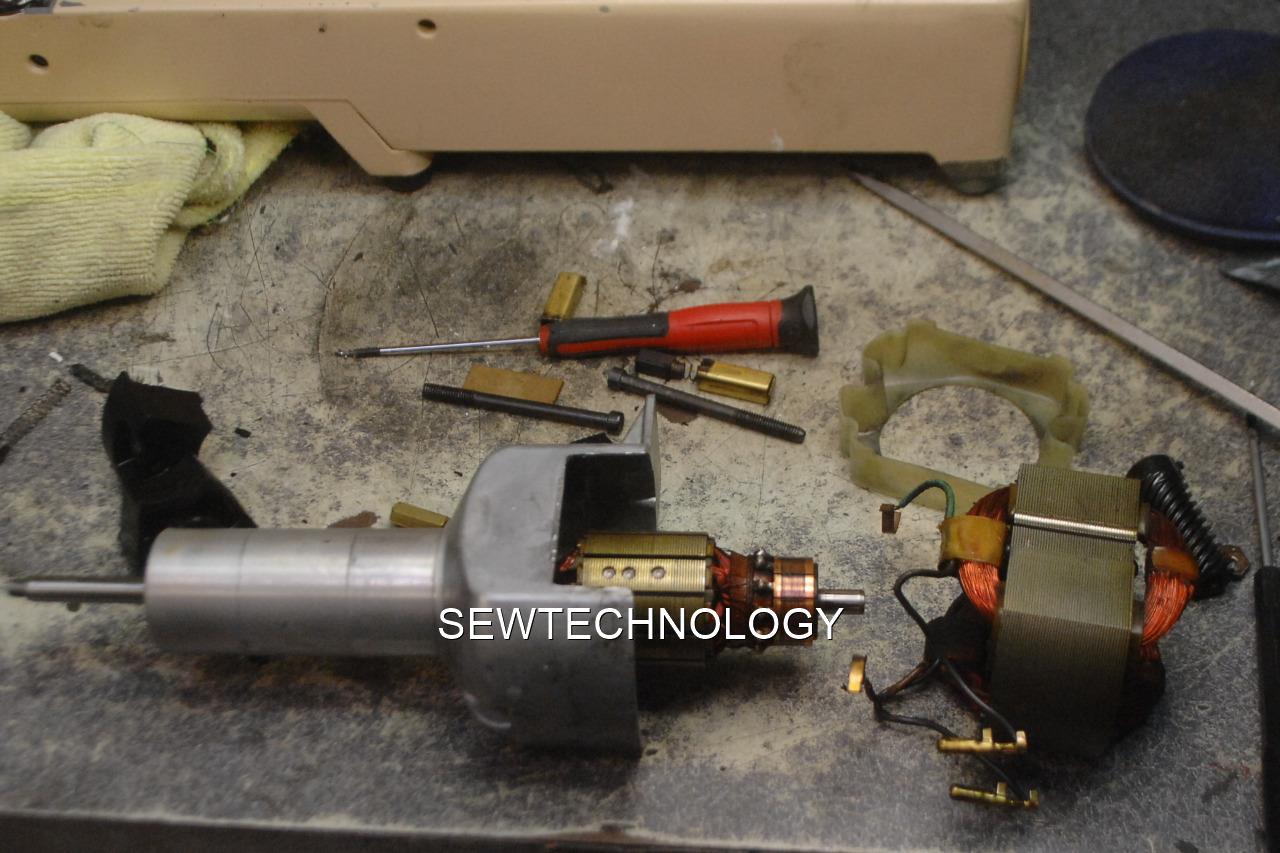

MOTOR FULLY SERVICED-- NEW BRUSHES, BEARING, & RESTORATION

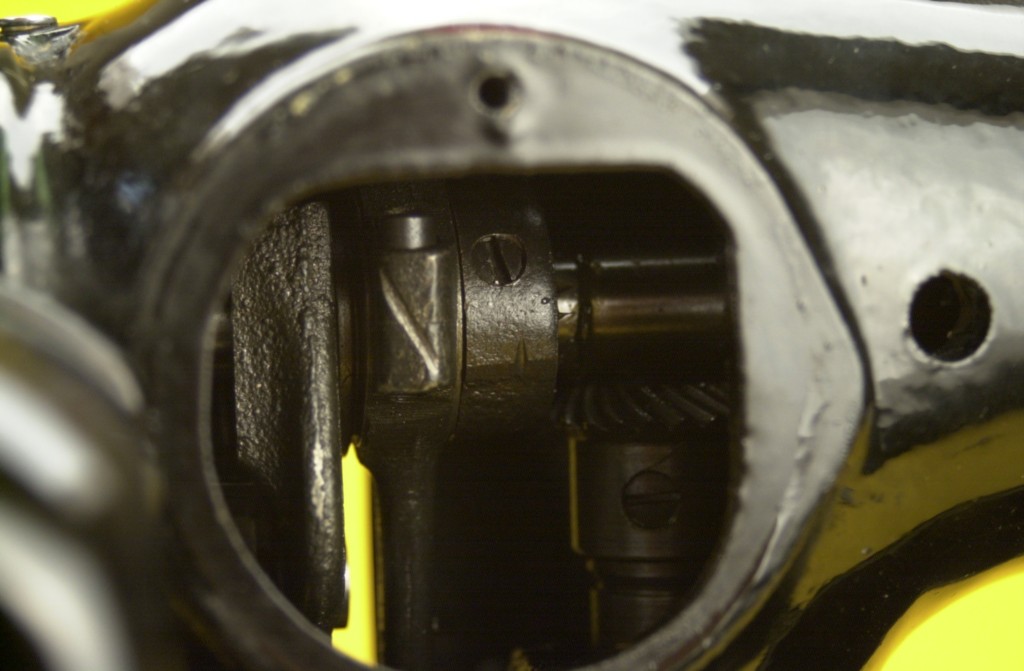

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

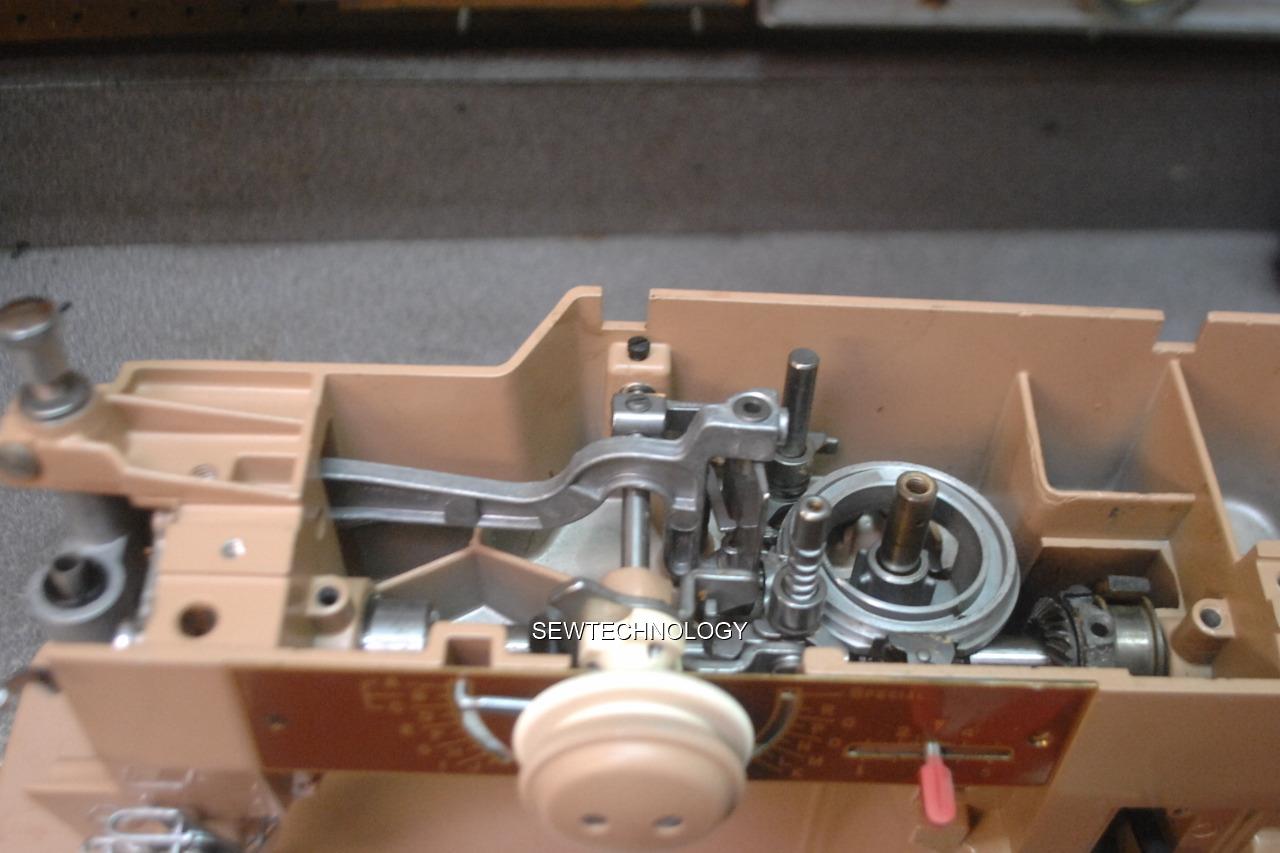

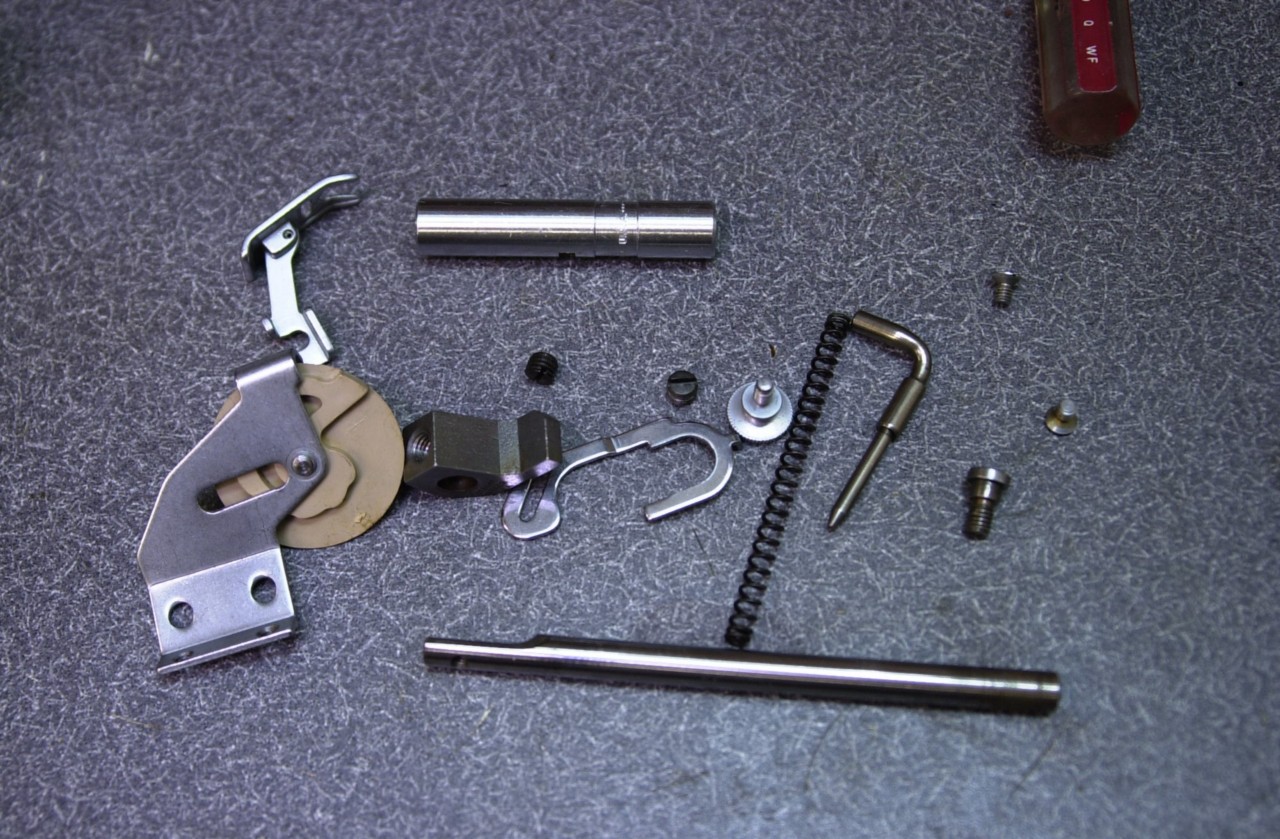

MOTOR AFTER RESTORATION

WIRING INSPECTED AND REPLACED

ALL RUBBER AND FELT COMPONENT'S REPLACED

CAMSTACK REMOVED CLEANED AND CHECKED FOR WEAR

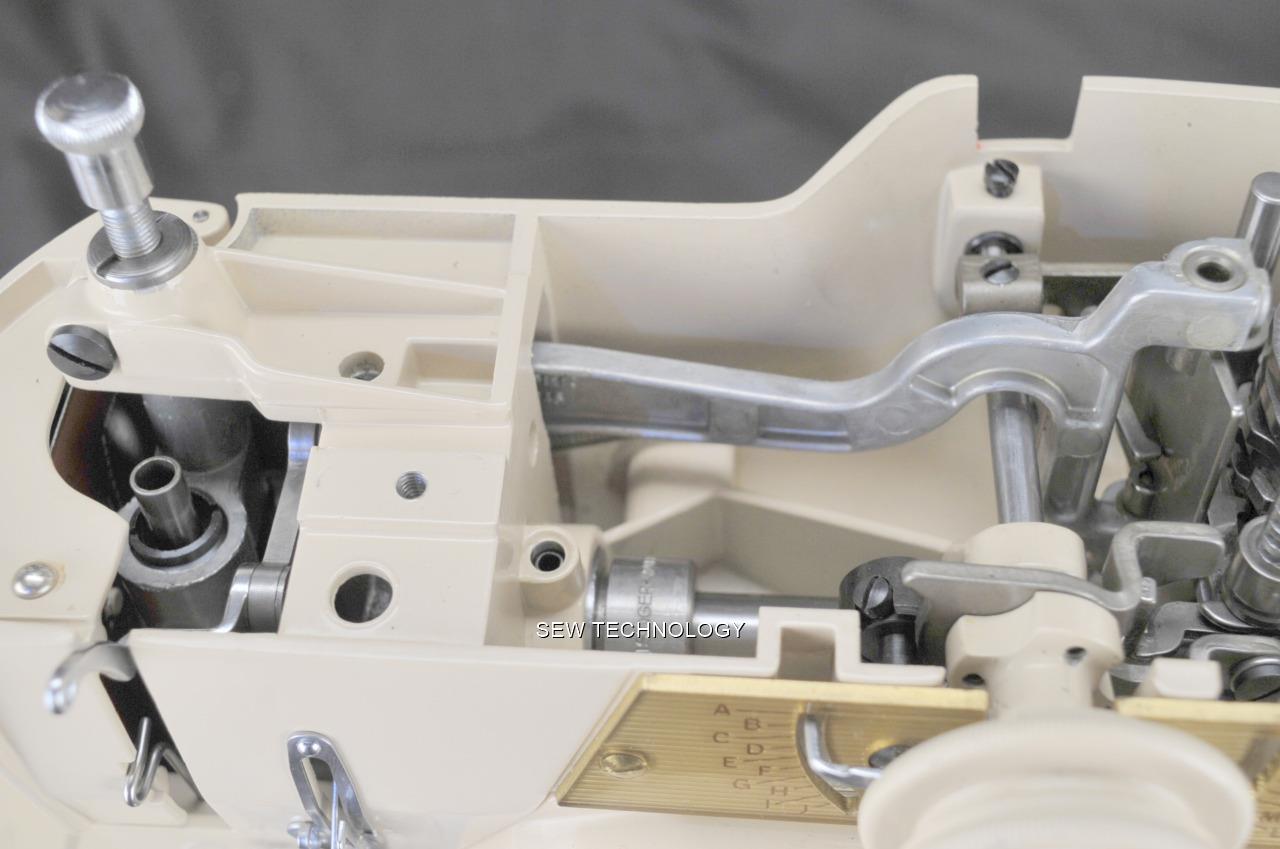

HEAD REBUILT

PRESSER FOOT REBUILT

BOBBIN REBUILT

NEEDLE CLAMP CLEANED

TENSIONER REBUILT

THROAT PLATE ASSEMBLY REBUILT

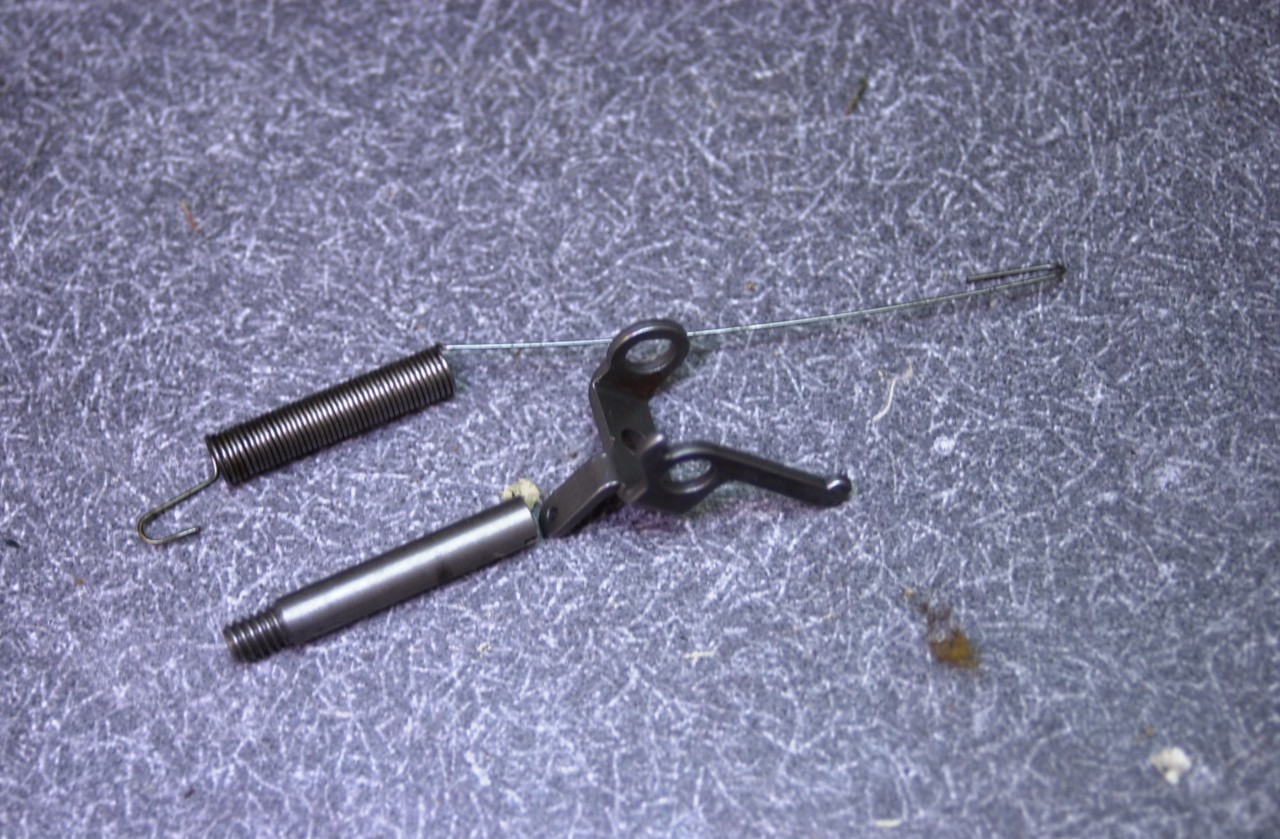

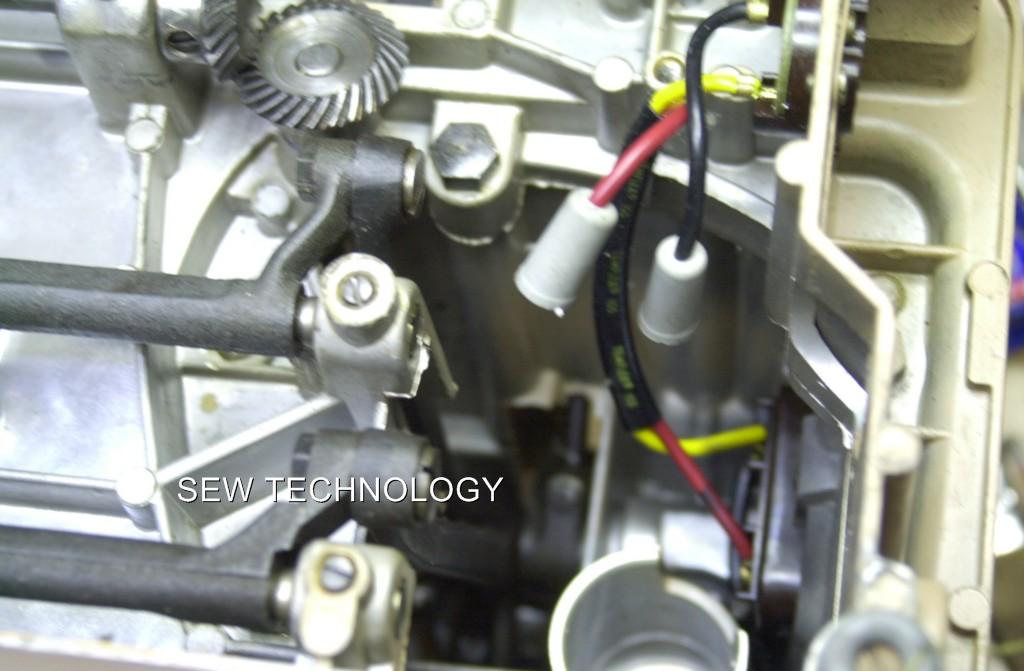

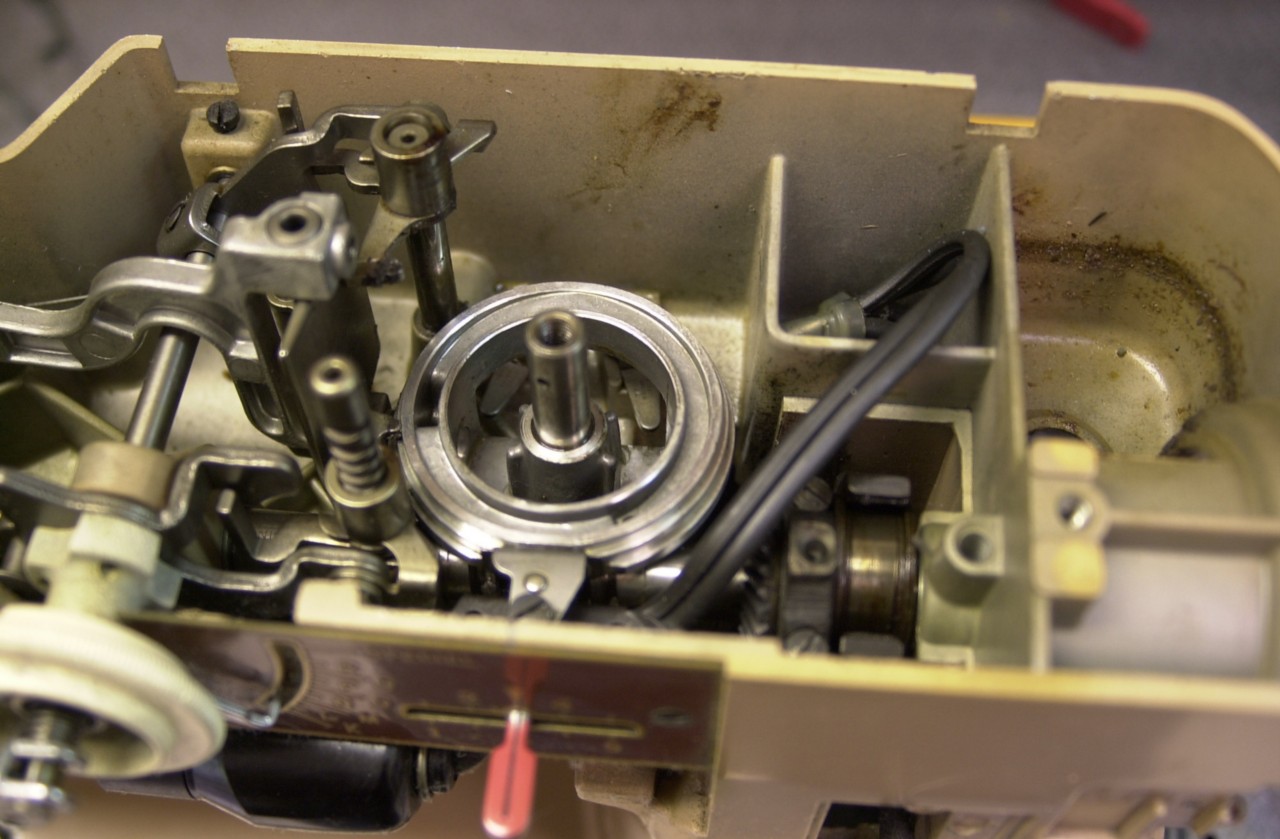

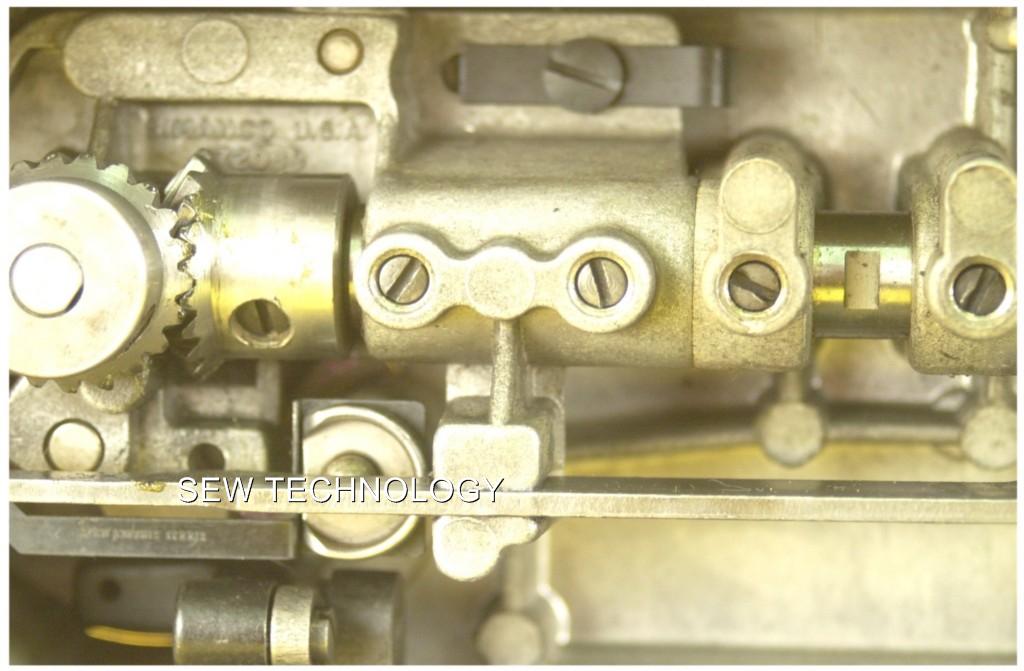

THE THROAT PLATE MECHANISM CAN BE PROBLEMATIC IF NOT SERVICED...WE COMPLETELY REBUILT THE SYSTEM

HERE IS THE BEFORE AND AFTER OF THE PLATE RISERS

STITCH LEVER SERVICED

FOOT PEDAL

COMPLETE ADJUSTMENT![]()

LOOK HOW CLEAN THIS MACHINE IS

![]()

IF YOU ARE IN THE MARKET FOR A GREAT 401A THIS IS IT

ACCESSORIES INCLUDED:

4 BOBBINS

8 CAMS INCLUDING

1,2,3,4,5,11,13,19

ZIPPER FOOT

ZIG ZAG FOOT

MULTI SLOTTED BINDER FOOT

STRAIGHT STITCH FOOT

BUTTON FOOT

SPECIAL PURPOSE FOOT

FOOT CONTROL

AK3 THROAT PLATE

SEAM GUIDE

MANUAL![]()

FEATURES:

INTERNAL FASHION STITCHES-- THE 401A HAS THE FAMOUS SINGER INTERNAL CAM STACK. OVER 60 STITCH DESIGNS AND VARIATIONS ARE POSSIBLE BY TURNING TWO FRONT SELECTOR KNOBS. IN ADDITION REMOVABLE TOP HAT CAMS ARE AVAILABLE TO CREATE AN ADDITIONAL 60 STITCH VARIATIONS

METAL GEARS-- THE 401A IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 401A IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

ADJUSTABLE STITCH LENGTH-- EASY TO ADJUST AT THE TOUCH OF A LEVER, SCREW ADJUSTMENT FOR FINE CHANGES

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT

ADJUSTABLE TENSION-- EASY TO REGULATE TENSION KNOB WILL ACCEPT TWO THREADS FOR TWIN NEEDLE SEWING

![]()

LID SHOWS SMALL SELECTION OF DECORATIVE STITCH VARIATIONS

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H)

- Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Built in cam stack with zigzag and decorative stitch capabilities

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs don't drop

- Easy to adjust tension system

- Light at the front of the machine

- Original foot controller- carbon pile, button style

- Adjustable stitch length and full reverse

- Easy adjustment of needle position

- Adjustable stitch width

- Twin needle and double needle capable

- Built-in threading chart on door

- Drop-in bobbin - no need to tilt machine to change

- Over 60 Built-in decorative stitches - plus cam stitches

- Left-Center-Right Needle positions

- Top mounted stitch chart - see the settings at a glance.

- Lever operated throat plate - just shift the lever to raise the plate for embroidery, darning, and free motion work

- Built-in light lights the entire work area

- Reversible feed - sew backward at the lift of a lever

- Unlimited stitch length and width regulation

- Needle clamp holds one twin needle OR TWO REGULAR NEEDLES for twin needle stitching.

- Aluminum construction - Durable and lightweight

- Can be mounted in a table, in a portable case, or used as-is on your tabletop

Uses common class 66 bobbins

- Uses common 15x1 needles

![]()

SAMPLE DECORATIVE STITCH VARIATIONS

FRONT AND BACK OF SAMPLE CAMS STITCHES

SAMPLE STITCHES SEWN WITH TWO DIFFERENT THREADS TO SHOW BALANCED STITCH

.

SERIAL # NB851775

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENT'S MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

THIS IS A EXCELLENT SINGER 500A SEWING MACHINE

The Singer 500 was the evolution of their highly successful 401 series machine. In the late 50's and 60's, Singer decided to jump into the streamlining "Space Age" craze that was sweeping the country. With minor exception, the 500 was a 401 with a different case.

The 500A Slant-O-Matic feature moves the needle over 1-inch closer to the operator. The average bed is 7 inches wide and the needles are usually centered. On the Slant-O-Matic, the needle is less than 2-1/2 inches from the edge of the bed.

The machine features a all metal gear driven slant needle, zig zag design with internal design disks. The 500, or Rocketeer, was the later version of the Singer 401, with a few minor changes. Most of the changes were cosmetic, the motor, drive, cam, and hook system remained the same. The major changes were:

The bobbin winder was changed to an internal design

An additional thread take up was added

The presser foot tension was changed to a dial

The top lid was changed and incorporated fold down spool holders

An intermediate position was labeled to the throat lift plate for darning or free motion sewing

The Singer 500 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary

hook. It’s ability to produce many decorative stitches with the built-in cam stack and additional, external cams make it an extremely versatile workhorse.

IN 1960 THIS MACHINE COST $350...YOU KNOW WHAT IT WOULD COST TODAY?...$0.00...BECAUSE YOU CAN NOT GET AN ALL METAL SEWING MACHINE TODAY...THE ONLY OPTION IS A MACHINE WITH PLASTIC GEARS...THESE ARE NOT THE DISPOSABLE MACHINES PRODUCED TODAY...THESE MACHINES ARE BUILT TO LAST A LIFETIME

THIS 500 IS IN FANTASTIC CONDITION... THIS MACHINE IS IN EXCELLENT MECHANIC AND COSMETIC CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE.

THE REMOVABLE SPOOL HOLDER THAT FITS ON THE TOP OF THE MACHINE IS USUALLY BROKEN OR MISSING, SO WE MACHINE A NEW ONE OUT OF SOLID ALUMINUM,

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

MOTOR FULLY SERVICED-- NEW BRUSHES, BEARING, & RESTORATION

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

STITCH LENGTH SELECTOR REBUILT

WIRING REPLACED

ALL RUBBER AND FELT COMPONENTS REPLACED

BOBBIN REBUILT

TENSIONER REBUILT

THROAT PLATE ASSEMBLY REBUILT

PRESSER FOOT REBUILT

NEEDLE CLAMP CLEANED

NEW FOOT PEDAL

.CAMSTACK SERVICED

CAM SELECTOR REBUILT

BOBBIN WINDER SERVICED

LIGHT ASSEMBLY SERVICED

EVEN THE SMALLEST PARTS ARE ULTRASONICALLY CLEANED

LID ASSEMBLY REMOVED POP UP SPOOL PINS AND SPRINGS REPLACED

COMPLETE ADJUSTMENT

NEW MOTOR BEARINGS

NEW MOTOR BRUSHES

NEW WRIING

NEW FOOT PEDAL

NEW TENSIONER SPRINGS

NEW CAMSTACK SPRING

NEW FELT

NEW FEET

NEW OIL DRIP PAD

NEW ALUMINUM SPOOL PIN![]()

LOOK HOW CLEAN THIS MACHINE IS

![]()

IF YOU ARE IN THE MARKET FOR A LIKE NEW 500 THIS IS IT

ACCESSORIES INCLUDED:

6 BOBBINS

8 CAMS INCLUDING

1,2,3,4,5,6,7,15

ZIPPER FOOT

ZIG ZAG FOOT

MULTI SLOTTED BINDER FOOT

STRAIGHT STITCH FOOT

HEMMER FOOT

BUTTON FOOT

SPECIAL PURPOSE FOOT .

.

STRAIGHT STITCH THROAT PLATE

FOOT CONTROL

MANUAL

![]()

FEATURES:

INTERNAL FASHION STITCHES-- THE 500 HAS THE FAMOUS SINGER INTERNAL CAM STACK. OVER 60 STITCH DESIGNS AND VARIATIONS ARE POSSIBLE BY TURNING TWO FRONT SELECTOR KNOBS. IN ADDITION REMOVABLE TOP HAT CAMS ARE AVAILABLE TO CREATE AN ADDITIONAL 60 STITCH VARIATIONS

METAL GEARS-- THE 500 IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 500 IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT![]()

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H) Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Built in cam stack with zigzag and decorative stitch capabilities

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs drop

- Light at the front of the machine

- ELECTRONIC FOOT CONTROL

- Adjustable stitch length and full reverse

- Easy adjustment of needle position

- Adjustable stitch width

- Twin needle and double needle capable

![]()

SAMPLE DECORATIVE STITCH VARIATIONS

FRONT AND BACK OF SAMPLE CAMS AND STITCHES

STITCHES SEWN WITH TWO DIFFERENT COLOR THREAD TO SHOW BALANCED STITCH

8 LAYERS OF CANVAS

6 LAYERS OF UPHOLSTERY FABRIC

6 LAYERS OF SUEDE

8 LAYERS OF DENIM

6 LAYERS OF DRAPERY MATERIAL

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENTS MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

.

.

THIS IS A EXCELLENT SINGER 401A SEWING MACHINE

The Singer 431 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary hook. It is based on the popular Singer 401 series, but fetures a free arm Its ability to produce many decorative stitches with the built-in cam stack and additional, external cams make it an extremely versatile workhorse. The 431 is considered by many to be the best machine Singer ever built. It is strong, versatile, and does a variety of stitches, and will stand the test of time. The 431 is a fantastic all purpose machines for altering, general, as well as home decor applications & various crafts. They have good piercing power when properly maintained and used with the correct needle and settings. They will stand up to heavy use and some abuse and still purr along nicely with only minor care. These machines were NOT cheap when when they were first produced. In 2010 dollars, a Singer 431 would run you about $2,800. These superbly crafted vintage machines will will long outlast any new machine on the market.

When this machine was produced, it cost about $350. Do you know what that would convert to in today's dollars? It would cost $0.00...you know why...you cant get an all metal gear driven machine, at any cost today

The 431 Slant-O-Matic feature moves the needle over 1-inch closer to the operator. The average bed is 7 inches wide and the needles are usually centered. On the Slant-O-Matic, the needle is less than 2-1/2 inches from the edge of the bed.

The machine features a all metal gear driven slant needle, zig zag design with internal design disks.

THIS 431 IS IN GREAT CONDITION... THIS MACHINE IS IN EXCELLENT MECHANIC AND VERY GOOD COSMETIC CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE. .BED PAINT HAS SOME LIGHT PIN SCRATCHES AND MARKS

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

![]()

COMPLETELY SERVICED

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

MOTOR FULLY SERVICED-- NEW BRUSHES, BEARING, & RESTORATION

ORIGINAL MOTOR HAD A PLASTIC UPPER BEARING HOUSING MADE IN FRANCE...IT TENDED TO GET WEAK WITH AGE AND BREAK CAUSING THE UPPER BEARING TO COME LOOSE..WE REPLACE IT WITH THE U.S. VERSION ALUMINUM HOUSING

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

MOTOR AFTER RESTORATION

WIRING INSPECTED AND REPLACED

ALL RUBBER AND FELT COMPONENT'S REPLACED

CAMSTACK REMOVED CLEANED AND CHECKED FOR WEAR

HEAD REBUILT

PRESSER FOOT REBUILT

BOBBIN REBUILT

NEEDLE CLAMP CLEANED

TENSIONER REBUILT

STITCH LEVER SERVICED

NEW FOOT PEDAL

COMPLETE ADJUSTMENT![]()

LOOK HOW CLEAN THIS MACHINE IS

![]()

IF YOU ARE IN THE MARKET FOR A GREAT 431 THIS IS IT

ACCESSORIES INCLUDED:

4 BOBBINS

9 CAMS INCLUDING

1,2,3,4,5,6,13,19,20

RUFFLER FOOT

ZIPPER FOOT

ZIG ZAG FOOT

MULTI SLOTTED BINDER FOOT

STRAIGHT STITCH FOOT

BUTTON FOOT

SPECIAL PURPOSE FOOT

HEMMER FOOT

DARNING PLATE

STRAIGHT STITCH PLATE

FOOT CONTROL

SEAM GUIDE

CHAINSTITCH ATTACHMENT

MANUAL![]()

FEATURES:

INTERNAL FASHION STITCHES-- THE 401A HAS THE FAMOUS SINGER INTERNAL CAM STACK. OVER 60 STITCH DESIGNS AND VARIATIONS ARE POSSIBLE BY TURNING TWO FRONT SELECTOR KNOBS. IN ADDITION REMOVABLE TOP HAT CAMS ARE AVAILABLE TO CREATE AN ADDITIONAL 60 STITCH VARIATIONS

METAL GEARS-- THE 401A IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 401A IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

ADJUSTABLE STITCH LENGTH-- EASY TO ADJUST AT THE TOUCH OF A LEVER, SCREW ADJUSTMENT FOR FINE CHANGES

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT

ADJUSTABLE TENSION-- EASY TO REGULATE TENSION KNOB WILL ACCEPT TWO THREADS FOR TWIN NEEDLE SEWING

![]()

LID SHOWS SMALL SELECTION OF DECORATIVE STITCH VARIATIONS

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H)

- Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Built in cam stack with zigzag and decorative stitch capabilities

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs don't drop

- Easy to adjust tension system

- Light at the front of the machine

- Original foot controller- carbon pile, button style

- Adjustable stitch length and full reverse

- Easy adjustment of needle position

- Adjustable stitch width

- Twin needle and double needle capable

- Built-in threading chart on door

- Drop-in bobbin - no need to tilt machine to change

- Over 60 Built-in decorative stitches - plus cam stitches

- Left-Center-Right Needle positions

- Top mounted stitch chart - see the settings at a glance.

- Lever operated throat plate - just shift the lever to raise the plate for embroidery, darning, and free motion work

- Built-in light lights the entire work area

- Reversible feed - sew backward at the lift of a lever

- Unlimited stitch length and width regulation

- Needle clamp holds one twin needle OR TWO REGULAR NEEDLES for twin needle stitching.

- Aluminum construction - Durable and lightweight

- Can be mounted in a table, in a portable case, or used as-is on your tabletop

Uses common class 66 bobbins

- Uses common 15x1 needles

![]()

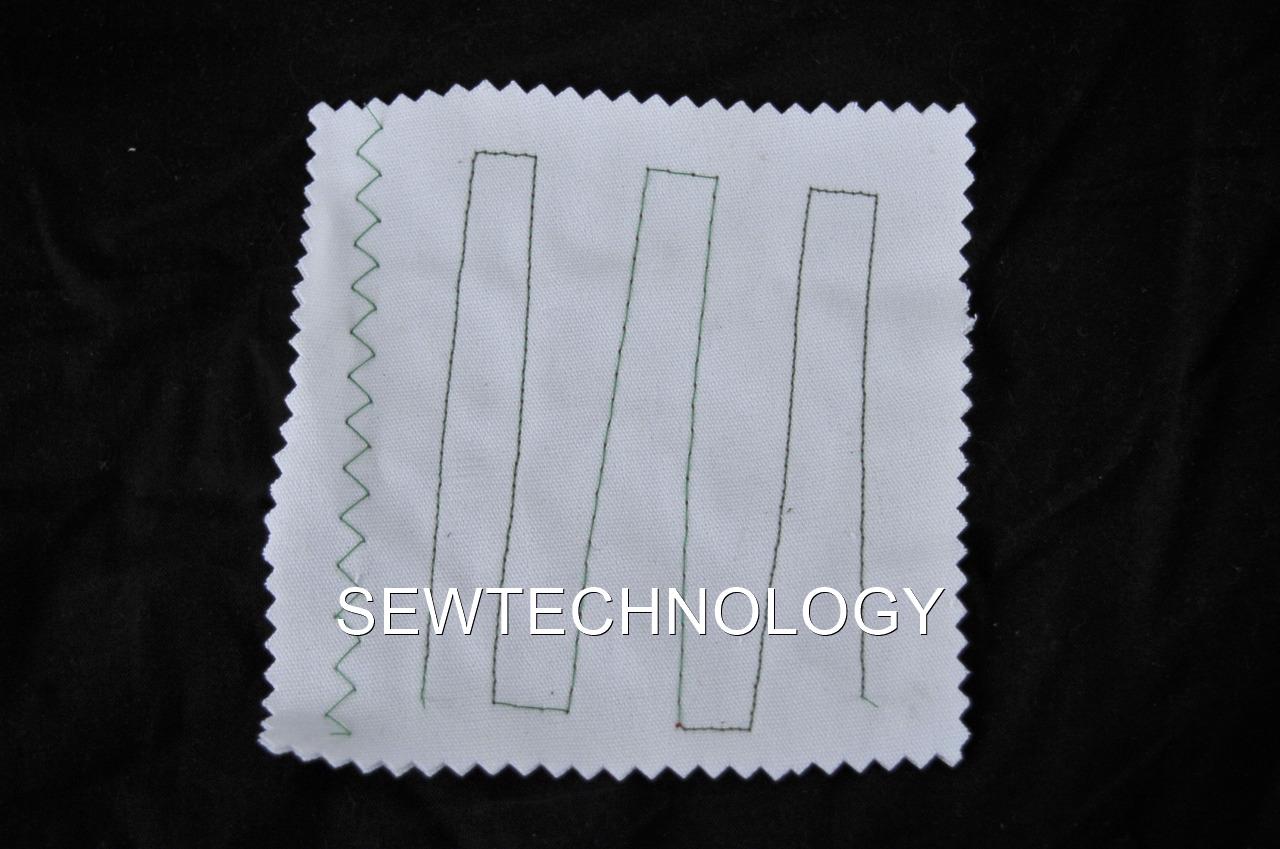

SAMPLE DECORATIVE STITCH VARIATIONS

FRONT AND BACK OF SAMPLE CAMS STITCHES

SAMPLE STITCHES SEWN WITH TWO DIFFERENT THREADS TO SHOW BALANCED STITCH

.

SERIAL # HB343414

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENT'S MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

THIS IS A EXCELLENT SINGER 404A SEWING MACHINE

The Singer 404 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary hook. The 400 series is considered by many to be the best machines Singer ever built. They are strong, versatile, , and will stand the test of time. The 404 is a fantastic all purpose machines for altering, general, as well as home decor applications & various crafts. They have good piercing power when properly maintained and used with the correct needle and settings. They will stand up to heavy use and some abuse and still purr along nicely with only minor care. These machines were NOT cheap when when they were first produced. In 2013 dollars, a Singer 404 would run you about $2,500. These superbly crafted vintage machines will will long outlast any new machine on the market.

When this machine was produced, it cost about $270 Do you know what that would convert to in today's dollars? It would cost $0.00...you know why...you cant get an all metal gear driven machine, at any cost today

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

THIS 503 IS IN GREAT CONDITION... THIS MACHINE IS IN EXCELLENT MECHANICAL CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE. ..BED PAINT IS EXCELLENT CONDITION...

![]()

COMPLETELY SERVICED

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

MOTOR FULLY REBUILT-- NEW BRUSHES, BEARING, & RESTORATION

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

STITCH LENGTH SELECTOR REBUILT

WIRING REPLACED

ALL RUBBER AND FELT COMPONENT'S REPLACED

BOBBIN REBUILT

TENSIONER REBUILT

THROAT PLATE ASSEMBLY REBUILT

PRESSER FOOT REBUILT

BOBBIN WINDER REBUILT

COMPLETE ADJUSTMENT![]()

LOOK HOW CLEAN THIS MACHINE IS

IF YOU ARE IN THE MARKET FOR A GREAT 404A THIS IS IT

ACCESSORIES INCLUDED:

6 BOBBINS

ZIPPER FOOT

STRAIGHT STITCH FOOT

RUFFLER FOOT

WALKING FOOT

FOOT CONTROL

MANUAL![]()

FEATURES:

METAL GEARS-- THE 404A IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 404A IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

ADJUSTABLE STITCH LENGTH-- EASY TO ADJUST AT THE TOUCH OF A LEVER, SCREW ADJUSTMENT FOR FINE CHANGES

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT

ADJUSTABLE TENSION-- EASY TO REGULATE TENSION KNOB WILL ACCEPT TWO THREADS FOR TWIN NEEDLE SEWING

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H)

- Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs don’t drop

- Easy to adjust tension system

- Light at the front of the machine

- Original foot controller- carbon pile, button style

- Adjustable stitch length and full reverse

SAMPLE STITCHES SEWN WITH TWO DIFFERENT THREADS TO SHOW BALANCED STITCH

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

METAL GEARS-- THE 503 IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 503 IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT![]()

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENT'S MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

SERIAL # AM216538

SINGER 403a

THIS IS A EXCELLENT SINGER 403A SEWING MACHINE

The Singer 403 is a sturdy built machine featuring and all metal construction, drop in bobbin and smooth rotary hook. It's ability to produce many decorative stitches with the external cams make it an extremely versatile workhorse. The 403 is considered by many to be one of the best machine Singer ever built. It is strong, versatile, and does a variety of stitches, and will stand the test of time. The 403 is a fantastic all purpose machines for altering, general, as well as home decor applications & various crafts. They have good piercing power when properly maintained and used with the correct needle and settings. They will stand up to heavy use and abuse and still purr along nicely with only minor care. These machines were NOT cheap when when they were first produced. In 2011 dollars, a Singer 403 would run you about $2,500. These superbly crafted vintage machines will will long outlast any new machine on the market.

When this machine was produced, it cost about $300. Do you know what that would convert to in today's dollars? It would cost $0.00...you know why...you cant get an all metal gear driven machine, at any cost today

The 403A Slant-O-Matic feature moves the needle over 1-inch closer to the operator. The average bed is 7 inches wide and the needles are usually centered. On the Slant-O-Matic, the needle is less than 2-1/2 inches from the edge of the bed.

The machine features a all metal gear driven slant needle, zig zag design.

THIS 403 IS IN GREAT CONDITION... THIS MACHINE IS IN EXCELLENT MECHANIC AND COSMETIC CONDITION. ...PURRS WONDERFULLY...GREAT RUNNING MACHINE. ONE OF THE BETTER 403'S WE HAVE HAD RECENTLY..BED PAINT IS EXCELLENT

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES

![]()

![]()

COMPLETELY SERVICED

FULL CLEANING -OLD GREASE COMPLETELY REMOVED

FULL LUBRICATION

MOTOR FULLY SERVICED-- NEW BRUSHES, BEARING, & RESTORATION

ARMATURE IS UNDERCUT, POLISHED AND RESTORED

MOTOR AFTER RESTORATION

WIRING INSPECTED AND REPLACED

ALL RUBBER AND FELT COMPONENT'S REPLACED

HEAD REBUILT

PRESSER FOOT REBUILT

BOBBIN REBUILT

NEEDLE CLAMP CLEANED

TENSIONER REBUILT

THROAT PLATE ASSEMBLY REBUILT

THE THROAT PLATE MECHANISM CAN BE PROBLEMATIC IF NOT SERVICED...WE COMPLETELY REBUILT THE SYSTEM

HERE IS THE BEFORE AND AFTER OF THE PLATE RISERS

STITCH LEVER SERVICED

FOOT PEDAL REBUILT

COMPLETE ADJUSTMENT![]()

LOOK HOW CLEAN THIS MACHINE IS

![]()

IF YOU ARE IN THE MARKET FOR A GREAT 403a THIS IS IT

ACCESSORIES INCLUDED:

5 BOBBINS

9 CAMS INCLUDING

0,1,2,3,4,5,8,9,

ZIPPER FOOT

ZIG ZAG FOOT

STRAIGHT STITCH FOOT

RUFFLER FOOT

SPECIAL PURPOSE FOOT

BINDER FOOT

HEMMER FOOT

FOOT CONTROL

MANUAL![]()

FEATURES:

INTERNAL FASHION STITCHES-- THE 403A TAKES EXTERNAL CAMS FOR OVER MULTIPLE STITCH DESIGNS AND VARIATIONS

METAL GEARS-- THE 403A IS AN EXTREMELY RELIABLE MACHINE. NO COMPUTERS TO FAIL, NO PLASTIC GEARS TO FAIL. NO BELTS TO BREAK. THE 403A IS ALL METAL GEAR DRIVEN MACHINE THAT WILL RUN FOR GENERATIONS

DROP IN BOBBIN-- TOP LOADING DROP IN BOBBIN FOR EASY COLOR CHANGES.

SLANT SHANK DESIGN-- GIVE GOOD VISIBILITY FOR THE WORK SURFACE, AND FOR EASIER THREADING

ADJUSTABLE STITCH LENGTH-- EASY TO ADJUST AT THE TOUCH OF A LEVER, SCREW ADJUSTMENT FOR FINE CHANGES

HEAVY DUTY-- THIS MACHINE SEWS EVERYTHING FROM THE MOST DELICATE SILKS TO LEATHERS AND CANVAS

ADJUSTABLE PRESSER FOOT PRESSURE-- EASY TO ADJUST PRESSURE FOOT

ADJUSTABLE TENSION-- EASY TO REGULATE TENSION KNOB WILL ACCEPT TWO THREADS FOR TWIN NEEDLE SEWING

![]()

- Full aluminum body with good size flat bed

- Weight - about 23 pounds

- Bobbin - class 66

- Needle system - standard sewing machine needles (15x1, 130/705H)

- Hook style - horizontal rotary

- Motor size - 0.723 amps

- Drive system - completely gear driven (no belts)

- Easy to use reverse

- Slant shank

- Adjustable presser foot pressure

- Elevator style throat plate - lifts up for darning and free-motion work - feed dogs don't drop

- Easy to adjust tension system

- Light at the front of the machine

- Original foot controller- carbon pile, button style

- Adjustable stitch length and full reverse

- Easy adjustment of needle position

- Adjustable stitch width

- Twin needle and double needle capable

- Drop-in bobbin - no need to tilt machine to change

- Left-Center-Right Needle positions .

- Lever operated throat plate - just shift the lever to raise the plate for embroidery, darning, and free motion work

- Built-in light lights the entire work area

Reversible feed - sew backward at the lift of a lever

- Unlimited stitch length and width regulation

- Needle clamp holds one twin needle OR TWO REGULAR NEEDLES for twin needle stitching.

- Aluminum construction - Durable and lightweight

- Can be mounted in a table, in a portable case, or used as-is on your tabletop

Uses common class 66 bobbins

- Uses common 15x1 needles

SAMPLE DECORATIVE STITCH VARIATIONS

FRONT AND BACK OF SAMPLE CAMS AND STITCHES

SAMPLE STITCHES SEWN WITH TWO DIFFERENT THREADS TO SHOW BALANCED STITCH

.

INCLUDES 90 DAY PARTS AND LABOR WARRANTY

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENT'S MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

SINGER 201-2 SEWING MACHINE

This machine runs very smoothly despite its industrial strength.

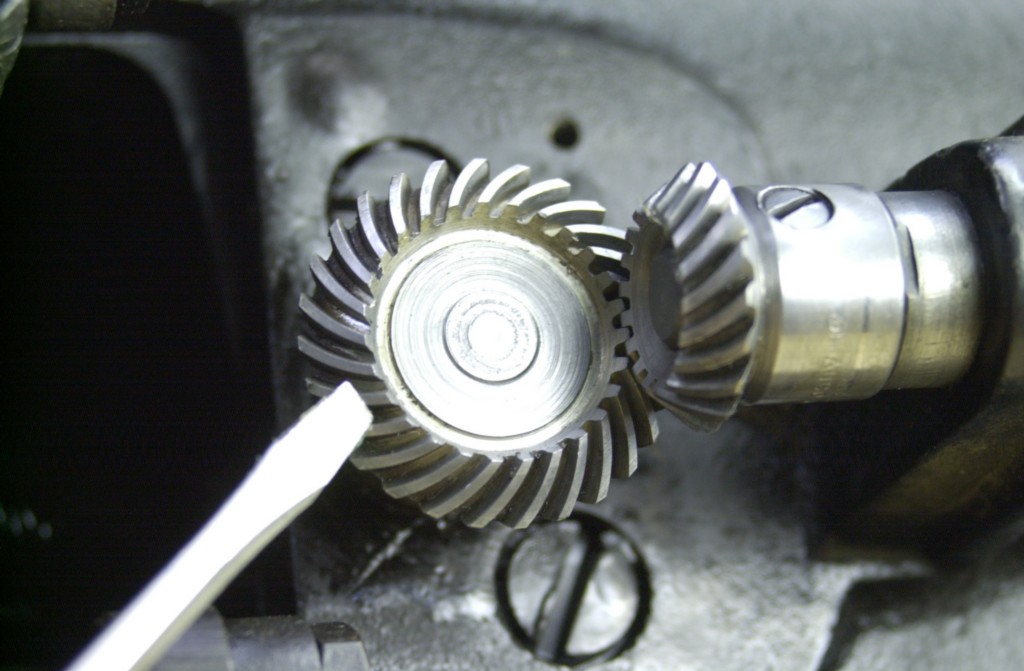

The 201 is considered by many to be the best sewing machine Singer ever produced. It features all metal construction, a full rotary hook driven by all metal spiral cut gears. Metal connecting rods and drive assemblies. There are no rubber belts to break..no fabric link belts to stretch. This particular 201 is EXTREMELY smooth...it makes only the quietest whir

![]()

The power of this machine is incredible. They will sew virtually anything that fits under the foot. Its has an internal gear driven motor that gives it the power of machines three times it's size.

8 LAYERS OF CANVAS

8 LAYERS OF DENIM

8 LAYERS OF SUEDE

8 LAYERS OF UPHOLSTERY

![]()

The possibilities are endless when working with a machine like this. It will go from 10 layers of outdoor canvas to a single layer of silk or crepe without missing a stitch. Even through leather, both the top and bottom stitch are evenly placed. Can accept up to a size 21...many current machines can only accept a size 16.

Very quiet and very fast

Great for beginners or experienced users. Good also for free motion quilting.... This is a machine you will cherish for generations.

![]()

Characteristics/Feature's :

![]()

1937 MODEL

PAINT ON MACHINE IS IN OVERALL IS IN EXCELLENT CONDITION--. . GOLD TRIM IS IN GREAT CONDITION AND 98% COMPLETE. .

Gear Driven--no belts to wear & slip

- built-in bobbin winder

- adjustable stitch length from 6-30

- adjustable tension system

- forward and reverse lever

- built-in light

-gear driven motor--no belt to slip or miss or wear out

-no plastic gears like those on more modern machines

- adjustable pressure foot system

- rotary hook

- original foot control

- all metal construction

- weight : approx. 38 pounds

![]()

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES INCLUDING:

![]()

FULL CLEANING OF MACHINE INSIDE AND OUT

OIL AND LUBRICATION OF ALL MOVING PARTS

ALL PARTS REMOVED CLEANED

This Singer was fully refurbished, which included the following

full cleaning....not just blown off with an air compressor

![]()

ALL WEAR POINTS MAGNIFLUXED* AND CHECKED AGAINST NEW SPECS.

TIMING CHECKED AND SET

TENSIONER COMPLETELY CLEANED, REBUILT AND ADJUSTED

FEED DOGS ARE CLEAN AND SHARP

NEEDLE CLAMP CLEANED

NUMBERS WERE RE STENCILED

PRESSER FOOT REBUILT

REBUILT MOTOR W/NEW SLEEVE BEARINGS, RE-MANUFACTURED ARMATURE, NEW BRUSHES

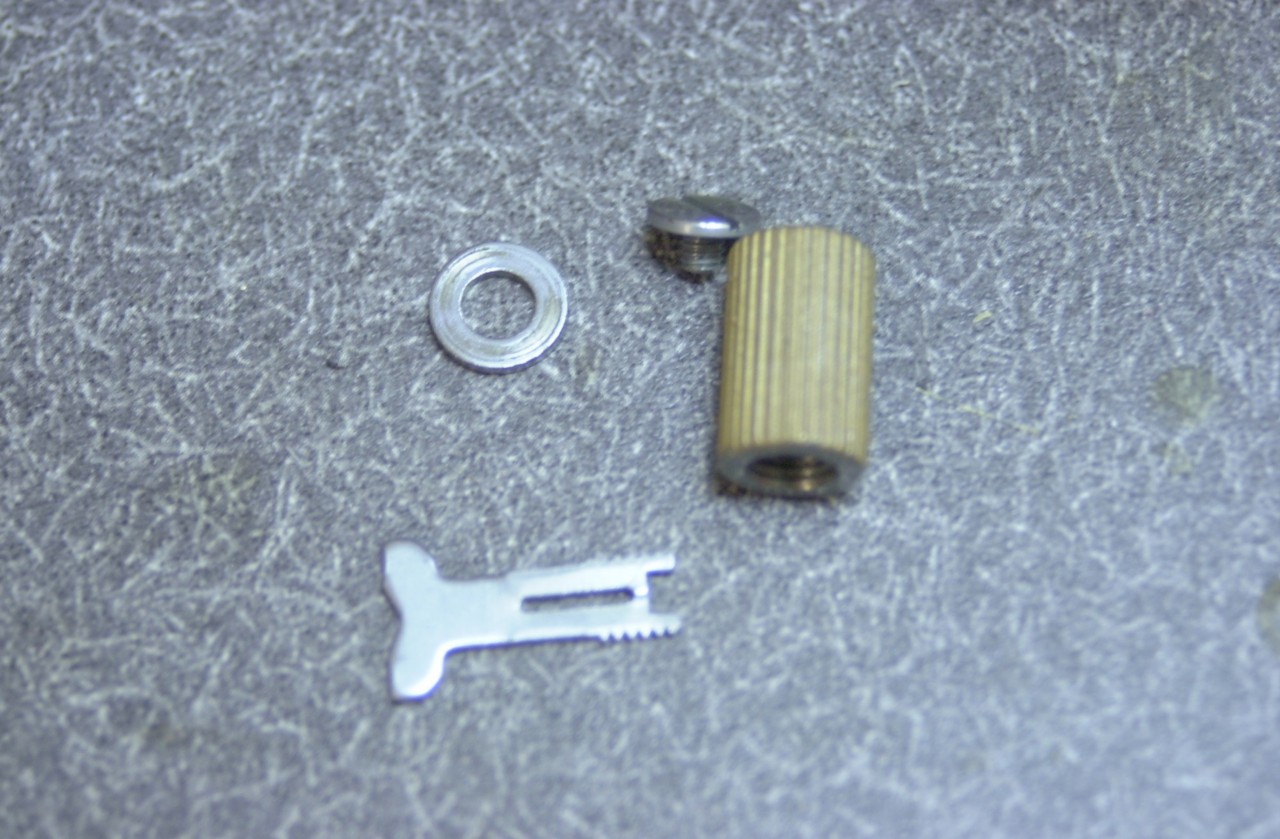

HERE IS A PIC SHOWING MOTOR IN RE-BUILDING PROCESS

ARMATURE AFTER SERVICING

MOTOR AFTER RE-BUILDING

COMPLETE DISASSEMBLE AND CLEANING OF HEAD

BOBBIN ASSEMBLY REBUILT

GREASE IS COMPLETELY CLEANED FROM GEARS AND REPLACED

NEW FOOT PEDAL

BOBBIN WINDER REBUILT

ROLLER BEARINGS REPLACED

NEW WIRING THROUGHOUT

EVERYTHING IS ULTRASONICALLY CLEANED

SEWING SAMPLE SHOWN FROM BOTH SIDES WITH TWO DIFFERENT COLOR THREADS TO SHOW BALANCED STITCH

![]()

ALL WIRING AND ELECTRICAL COMPONENTS REPLACED

ALL RUBBER, FELT AND WEAR COMPONENTS REPLACED

FEED DOGS ARE SHARP AND IN EXCELLENT CONDITION

COMPLETE ADJUSTMENT OF MACHINE

OUR TECHNICIAN HAS ALMOST 30 YRS EXPERIENCE AND SPENDS 8-10 HOURS ON EVERY MACHINE...EVEN ONE OF THIS QUALITY

INCLUDES 90 DAY WARRANTY ON PARTS AND LABOR

IF YOU ARE IN THE MARKET FOR A GREAT 201 THIS IS IT

ACCESSORIES INCLUDED:

5 BOBBINS

RUFFLER

ZIPPER FOOT

GENERAL PURPOSE FOOT

HEMMER FOOT

GATHERING FOOT

FOOT CONTROL

MANUAL

SERIAL # AE678552

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPO NETS MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

*Which means all wear and moving parts were removed ...dye checked for micro cracks, inspected for wear, and reinstalled.