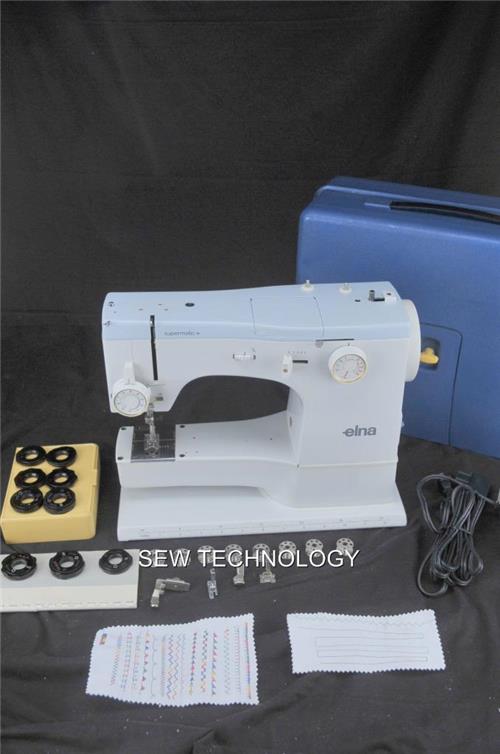

This hard to find ELNA 62c SEWING MACHINE

This machine runs very smoothly despite its industrial strength. It is a versatile machine sewing thru the Heaviest leather, and well as perfect stitches in delicate silks. The automatic bobbin winder is fully operational and the feed/needle plate assembly is in perfect working condition.

![]()

Characteristics/Feature's:

Top loading bobbin

-built-in bobbin winder

-Button hole setting

-Dual speed variable speed foot control

-Adjustable needle: center, right, left

-Variable width zig zag

-Dual needle capability

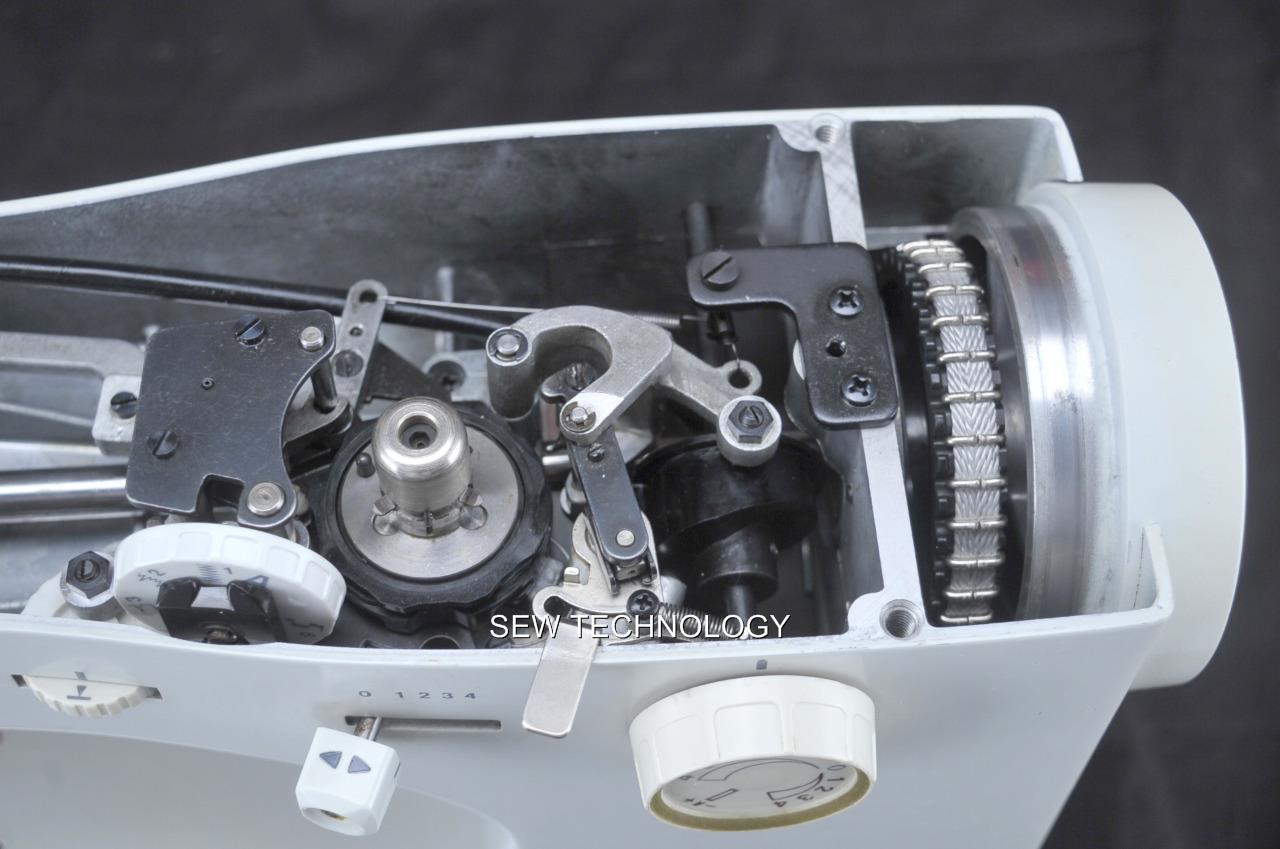

-Internal cam system for 6 built in stitches

- Additional cams for special stitches

-adjustable stitch control

- adjustable stitch length system

- adjustable tension system

- forward and reverse knob

- built-in light

-Electronic speed control

-Elna foot control and heavy duty cord

-cleated belt driven

- rotary hook

- all metal construction

- weight : approx. 28 pounds

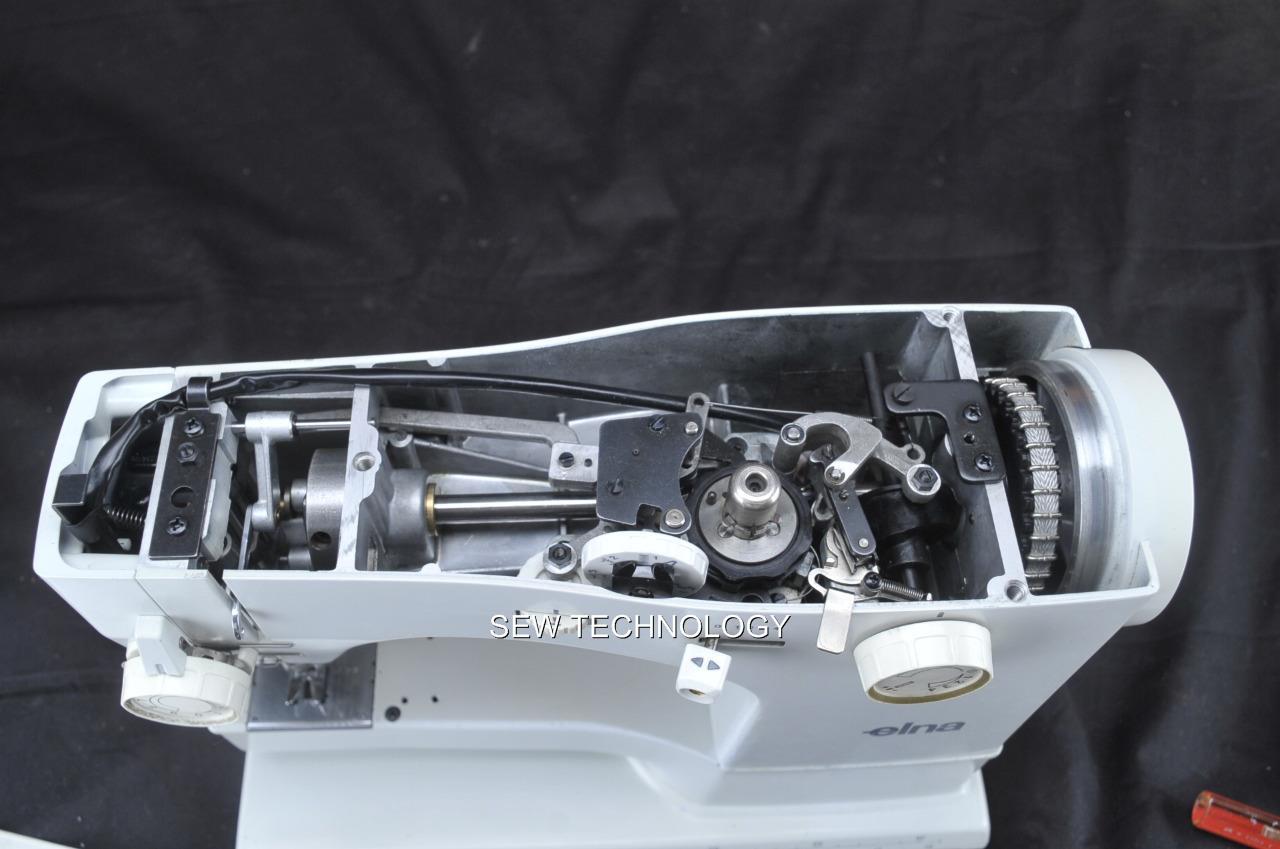

MACHINE IS IN EXCELLENT COSMETIC AND MECHANICAL CONDITION

![]()

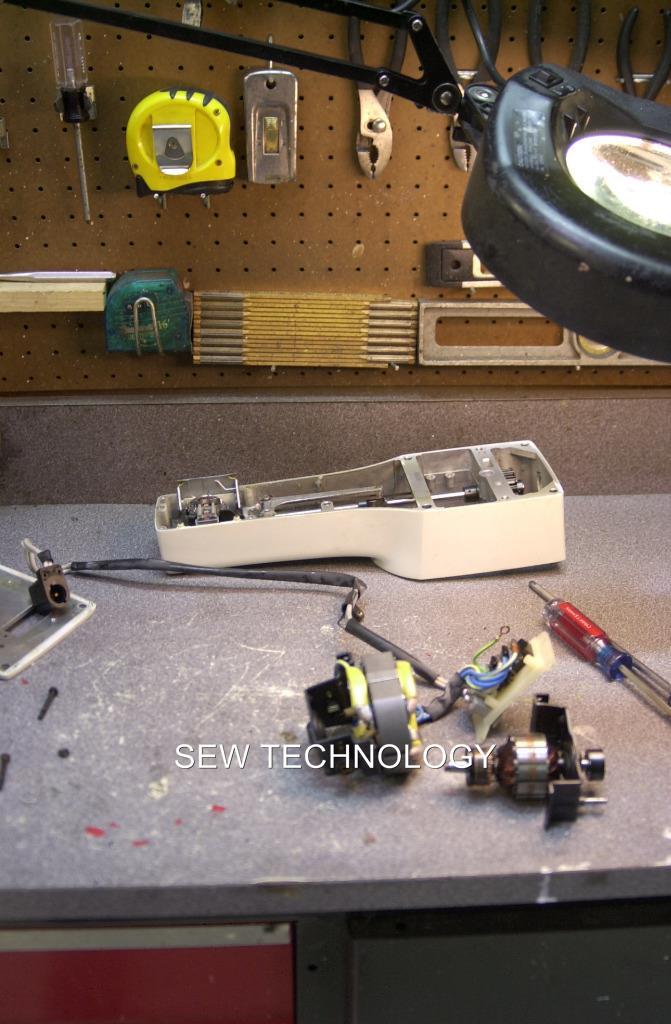

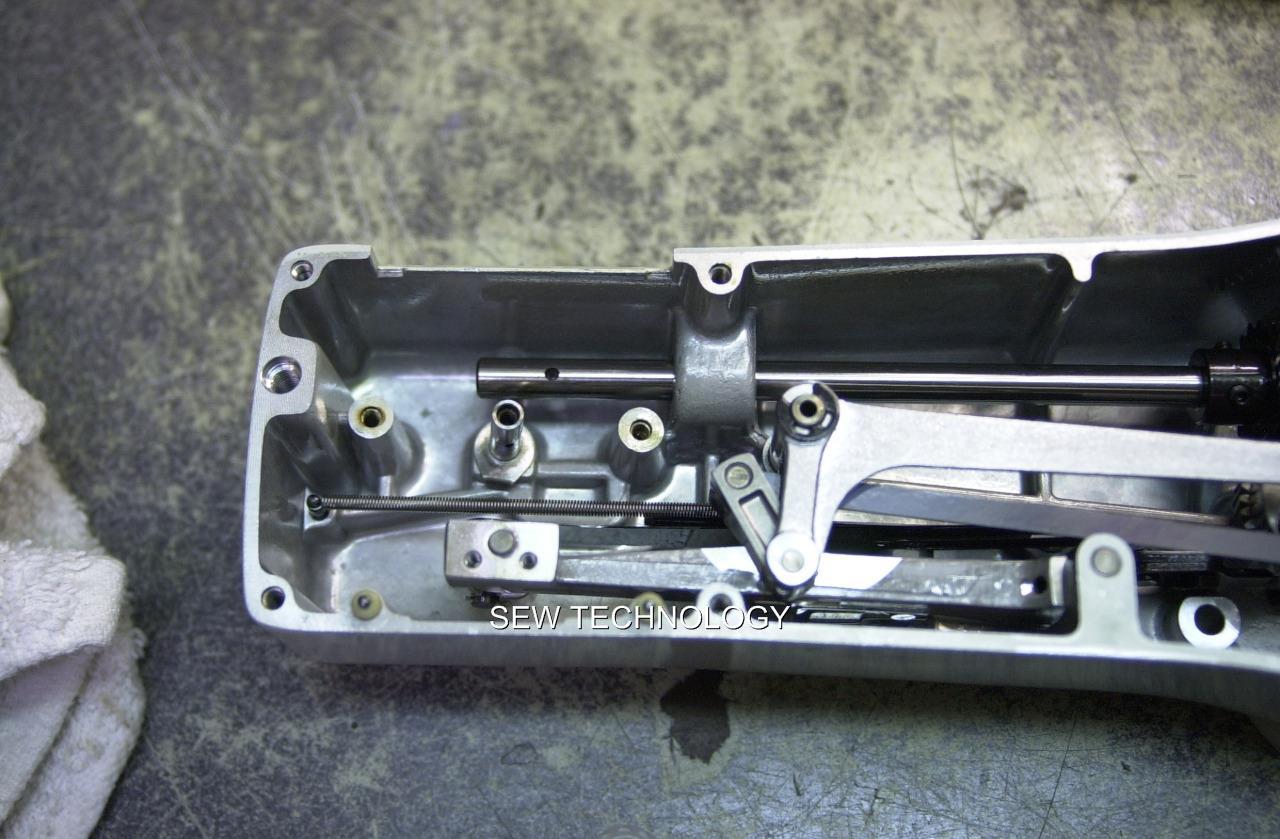

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES INCLUDING:

FULL CLEANING OF MACHINE AND RE-GREASE AND LUBRICATION OF ALL MOVING PARTS

This Elna was fully refurbished, which included the following

full cleaning....not just blown off with an air compressor

ALL WEAR POINTS MAGNIFLUXED* AND CHECKED AGAINST NEW SPECS.

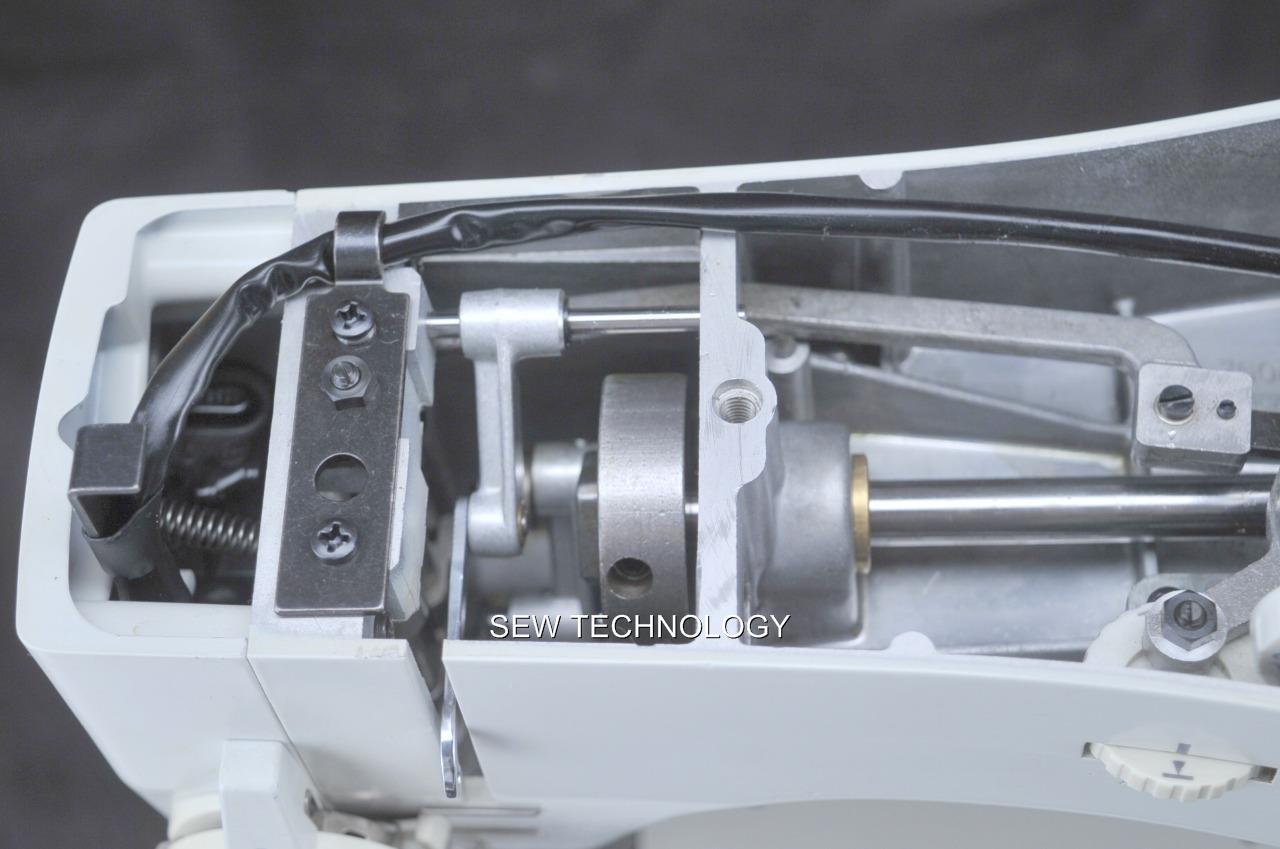

Motor was removed, armature cleaned, brushes replaced

ELNA MOTORS HAVE A RUBBER PULLEY WHEEL THAT WEARS AND CAUSES THE MACHINE TO SLIP..

ALSO THE MOTOR COPPER SLEEVE BEARING THAT WEAR WITH AGE

WE REPLACE THE PULLEY WHEEL AND BEARINGS WITH NEW

BOBBIN AND HOOK CLEANED

PRESSER FOOT CLEANED AND SERVICED

ALL WIRING AND ELECTRICAL COMPONENTS INSPECTED AND REPLACED

TENSIONER REBUILT

BOBBIN WINDER SERVICED

NEW FEET

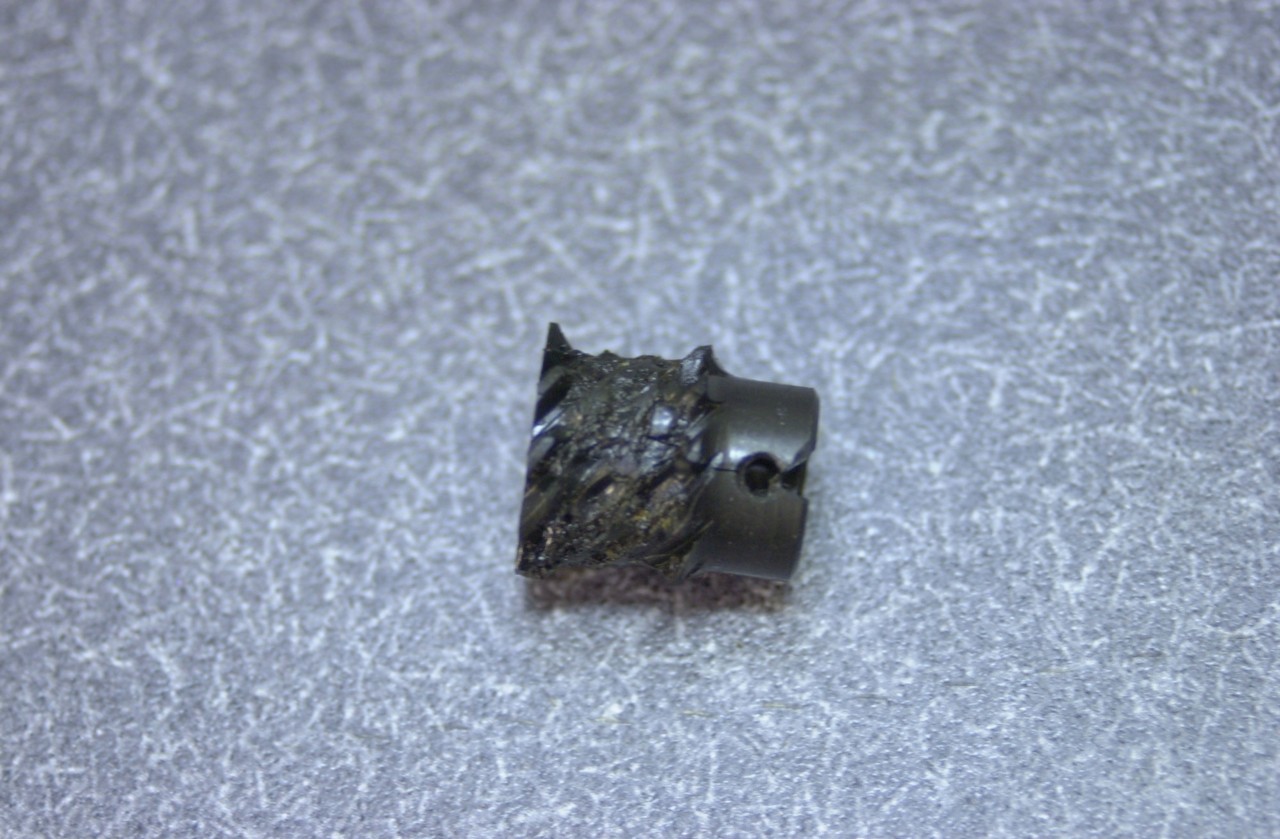

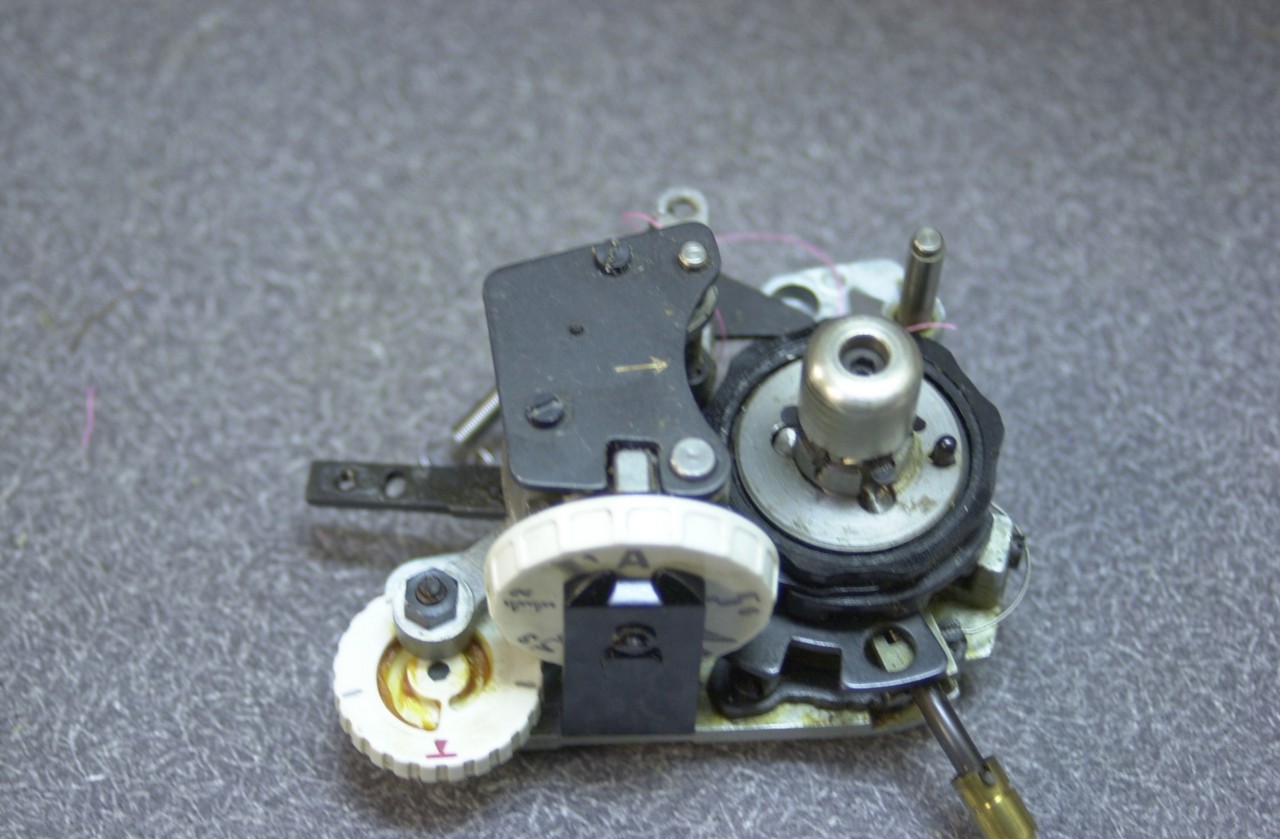

THERE ARE A COUPLE OF NYLON GEARS, LIKE THIS HOOK GEAR, ON THE SU THAT TEND TO DETERIORATE WITH AGE. WE REPLACE THESE WITH NEW ONES

EVEN THE SMALLEST PARTS ARE REMOVE ULTRASONIC CLEANED AND REPLACED

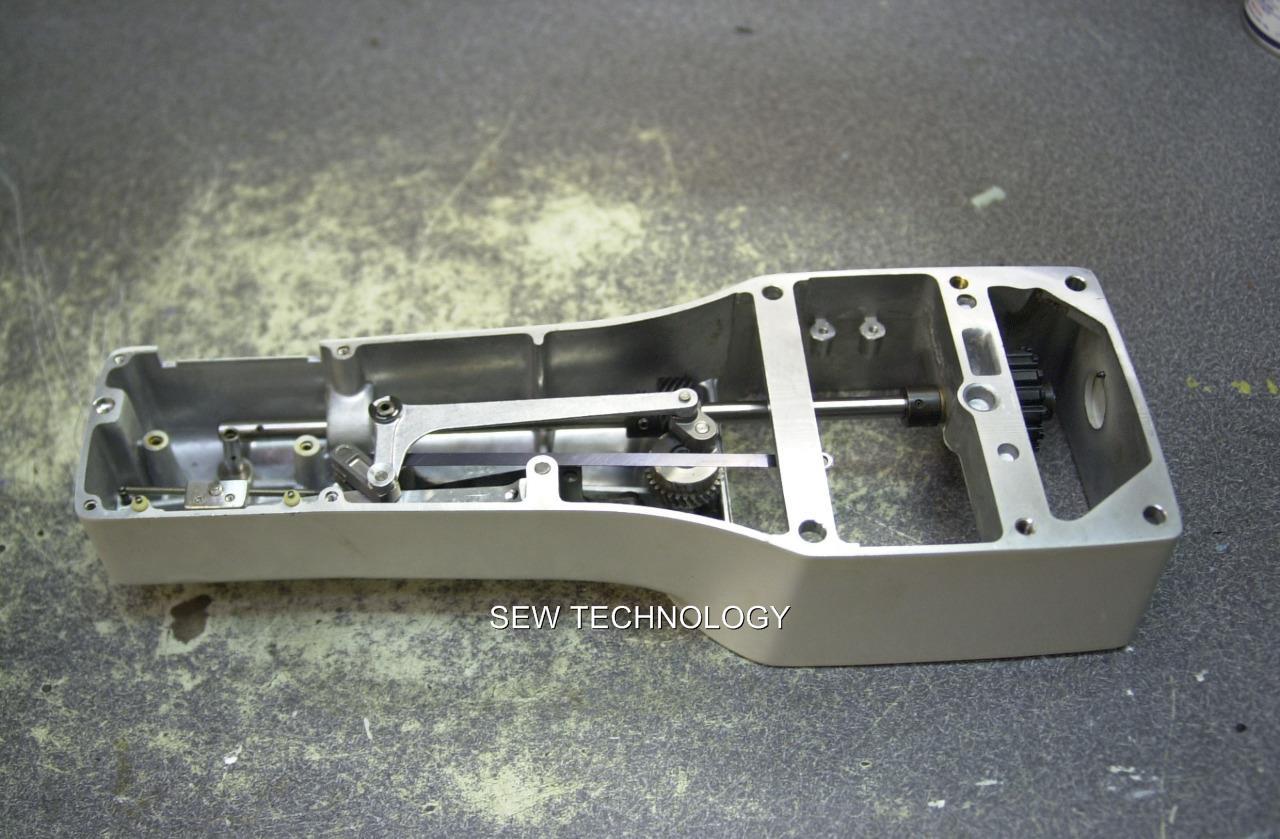

CAM GEAR SYSTEM REMOVED AND SERVICED

FEED DOGS ARE CLEAN AND SHARP

ALL WEAR COMPONENTS REPLACED

NEW CLEATED DRIVE BELT

LOOK HOW CLEAN THIS MACHINE IS NOW

![]()

IF YOU ARE IN THE MARKET FOR A LIKE NEW ELNA THIS IS IT

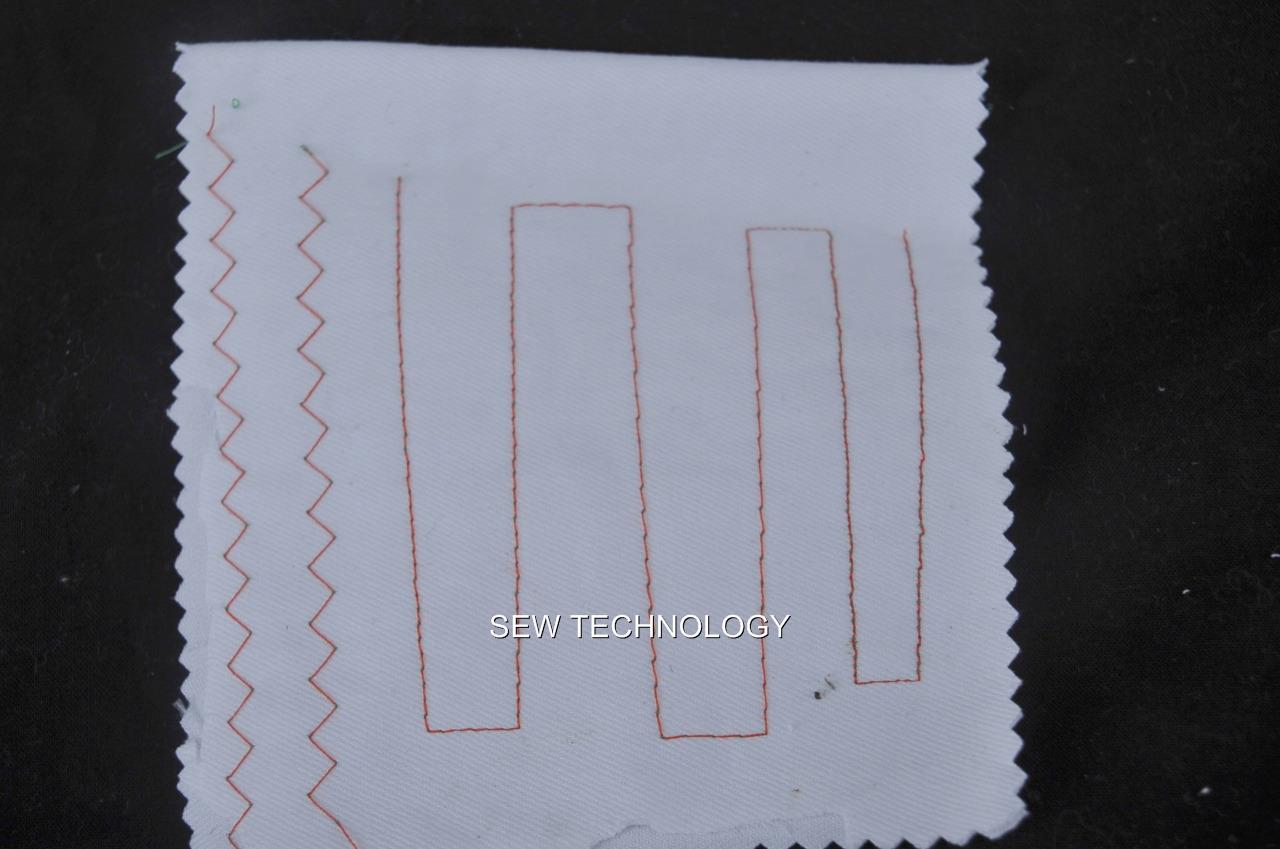

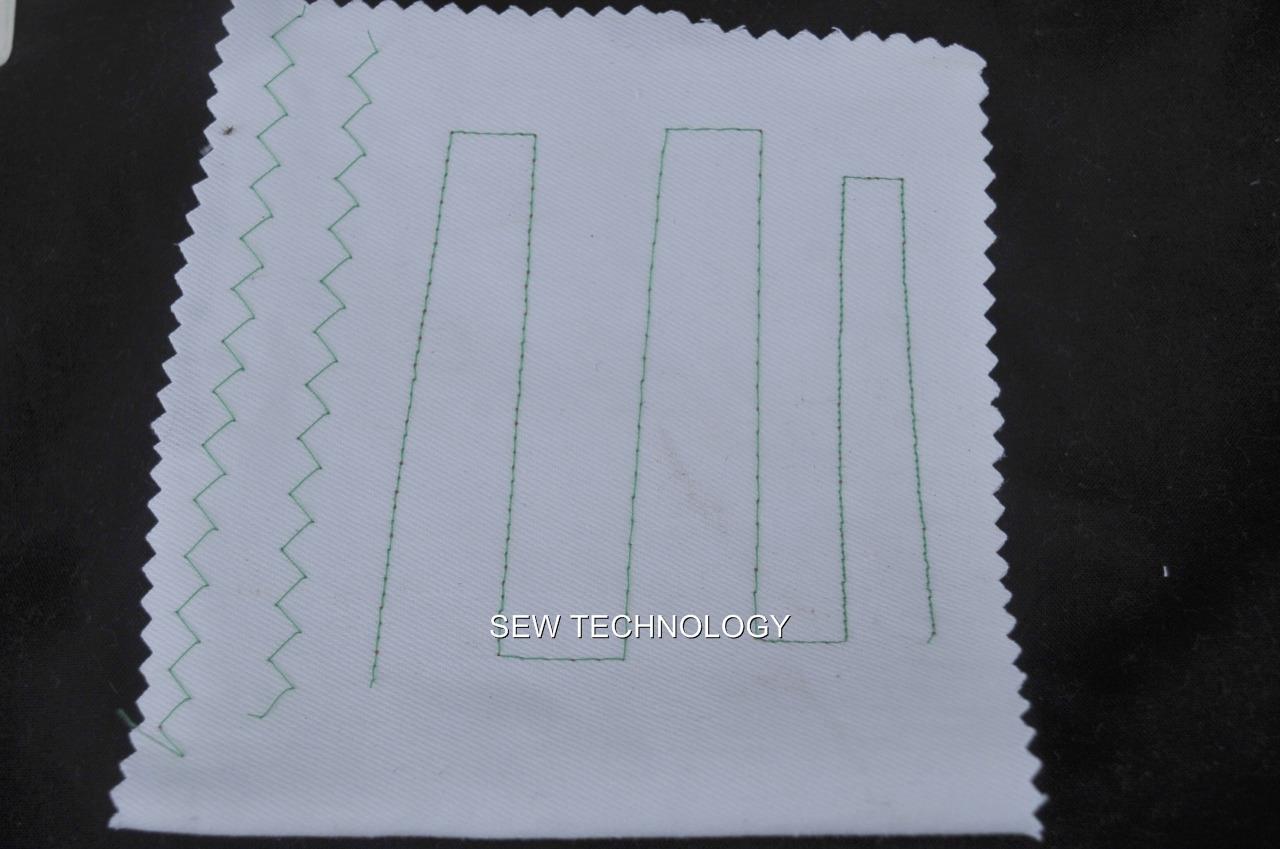

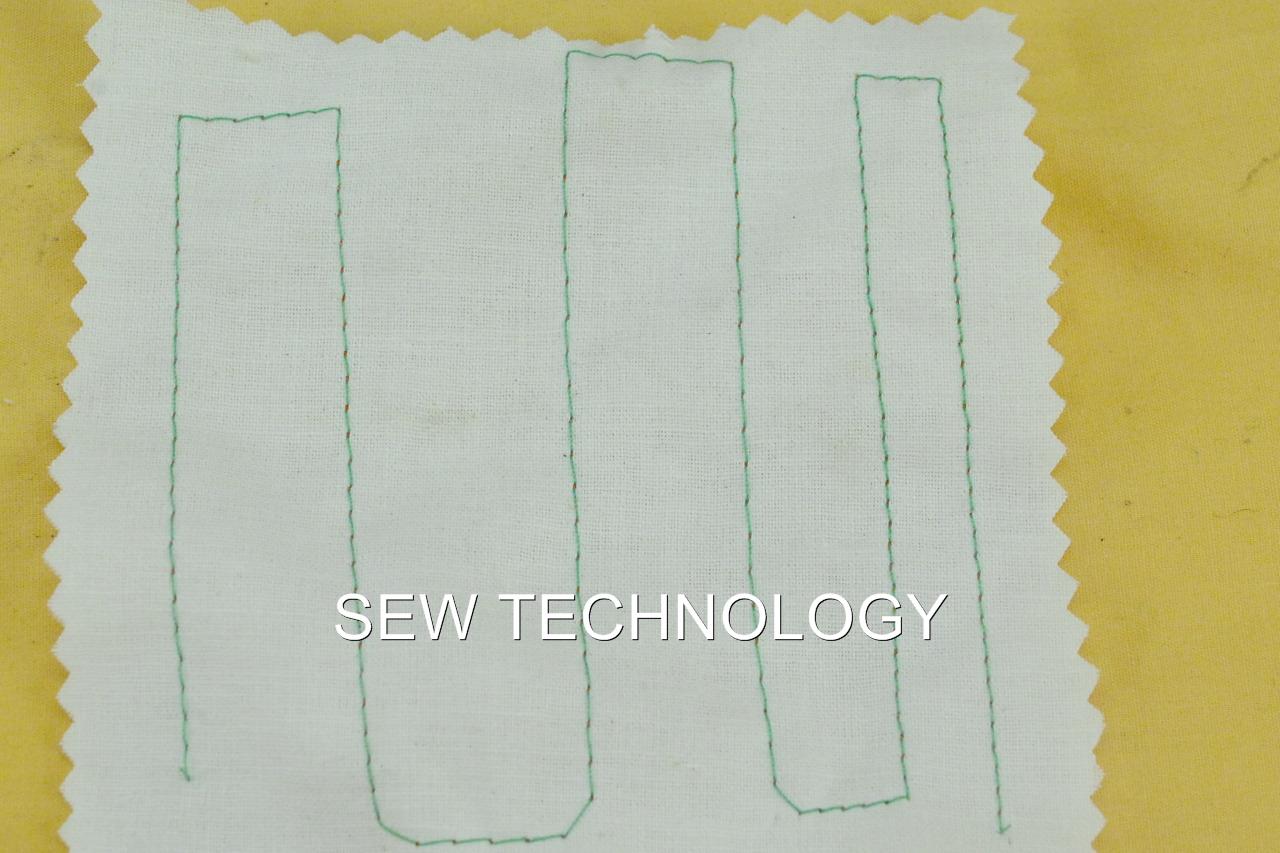

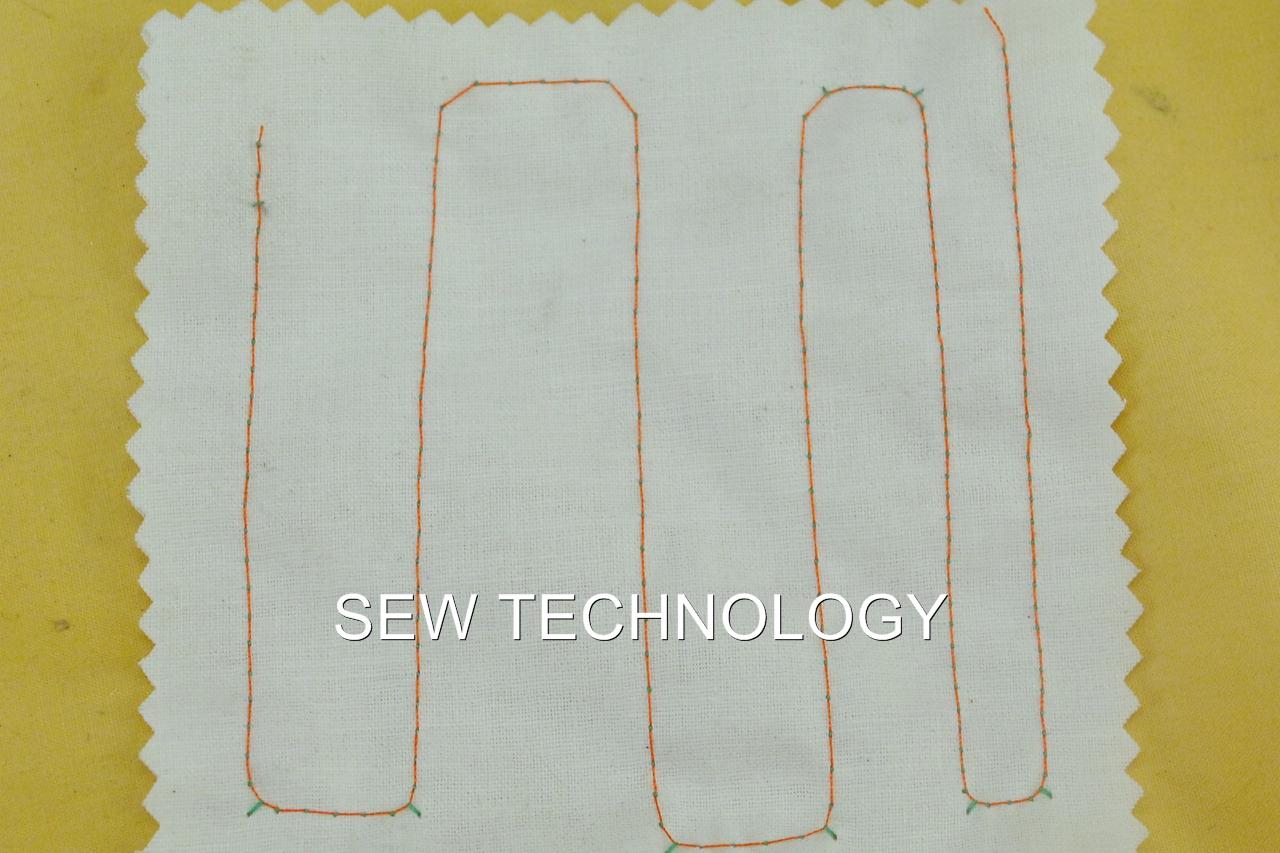

LOOK AT THE UNIQUE STITCHES...SHOWN FROM BOTH SIDES

BALANCED STITCH SHOWN FROM BOTH SIDES WITH TWO DIFFERENT COLOR THREADS

ACCESSORIES INCLUDED:

6 BOBBINS

10 EMBROIDERY CAMS INCLUDING

1,11,21,29,37,90,112,134,138,143

ZIGZAG FOOT

ZIPPER FOOT

CLEAR ZIGZAG FOOT

BUTTONHOLE FOOT

FOOT CONTROL

MANUAL

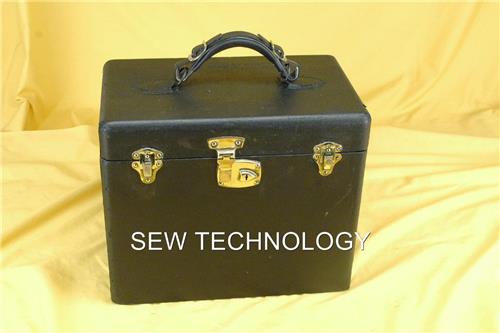

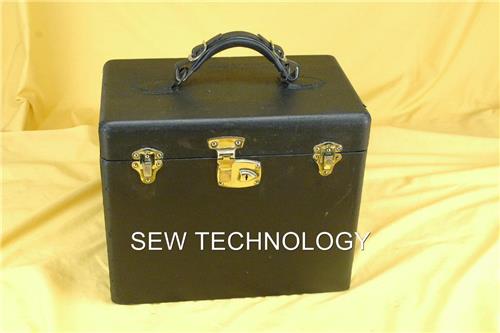

CASE

INCLUDES 90 DAY WARRANTY

SERIAL # C122873

![]()

*Which means all wear and moving parts were removed ...dye checked for micro cracks, inspected for wear, and reinstalled.

SEWHANDY SEWING MACHINE

SEWHANDY SEWING MACHINE

Originally designed in 1927, the Sewhandy was the brainchild of R Hohmann. He wanted something light, portable and compact. The country was growing and expanding, and the population was shifting to a city landscape. Small and efficient was perfect for the new city dweller. Hohmann originally contracted with the Osann company of New York to produce his design, Osann contracted with the Standard Sewing machine company, located in Cleveland to do the actual production. The Standard company was a much better known sewing machine manufacturer. Later Osann would acquire Standard sewing company. In 1931 Osann agreed to sell Sewhandy machines to General Electric, to be branded under their name. There was somewhat of a blurring of products during this time period. Some units where still sold as Sewhandy, while others bore the GE name. Late in 1934 Osann was sold to the Singer sewing machine company, and although Singer did maintain some production of some of the Osann line most had all but disappeared by 1938. The Sewhandy was definitely predated the Singer Featherweight, and the concept may have been used by Singer, but it is not by any means a Featherweight ancestor. The machines share only size in design.

SATISFACTION GUARANTEED

![]()

Very quiet and very fast

![]()

Characteristics/Feature's :

![]()

PAINT ON MACHINE IS IN MINT CONDITION...THE WHOLE MACHINE SHINES LIKE A MIRROR OR A NEW PAIR OF BLACK PATTON SHOES

GOLD TRIM IS CLEAR & COMPLETE IN EXCELLENT CONDITION

THIS IS A GREAT MACHINE...GUARANTEED TO PERFORM RIGHT OUT OF THE BOX

- built-in bobbin winder

- adjustable stitch length from 6-30

- adjustable tension system

- built-in light

-no plastic gears like those on more modern machines

Hook type: Rotary

Standard household sewing machine needles (system 15x1 aka 130/705H)

Motor: usually rated at about 0.6 amps

Presser feet: screw-on

Adjustable presser foot pressure

Adjustable stitch length

- ![]()

HAS JUST BEEN FULLY SERVICED BY SEW TECHNOLOGIES INCLUDING:

![]()

FULL CLEANING OF MACHINE INSIDE AND OUT

OIL AND LUBRICATION OF ALL MOVING PARTS

HEAD REBUILT

ALL OLD GREASE IS REMOVED AND REPLACED

This Sewhandy was fully refurbished, which included the following

full cleaning....not just blown off with an air compressor

![]()

ALL WEAR POINTS MAGNIFLUXED* AND CHECKED AGAINST NEW SPECS.

TIMING CHECKED AND SET

TENSIONER COMPLETELY CLEANED, REBUILT AND ADJUSTED

FOOT PRESSER ASSEMBLY SERVICED

REBUILT MOTOR W/ NEW SLEEVE BEARINGS, RE-MANUFACTURED ARMATURE, NEW BRUSHES

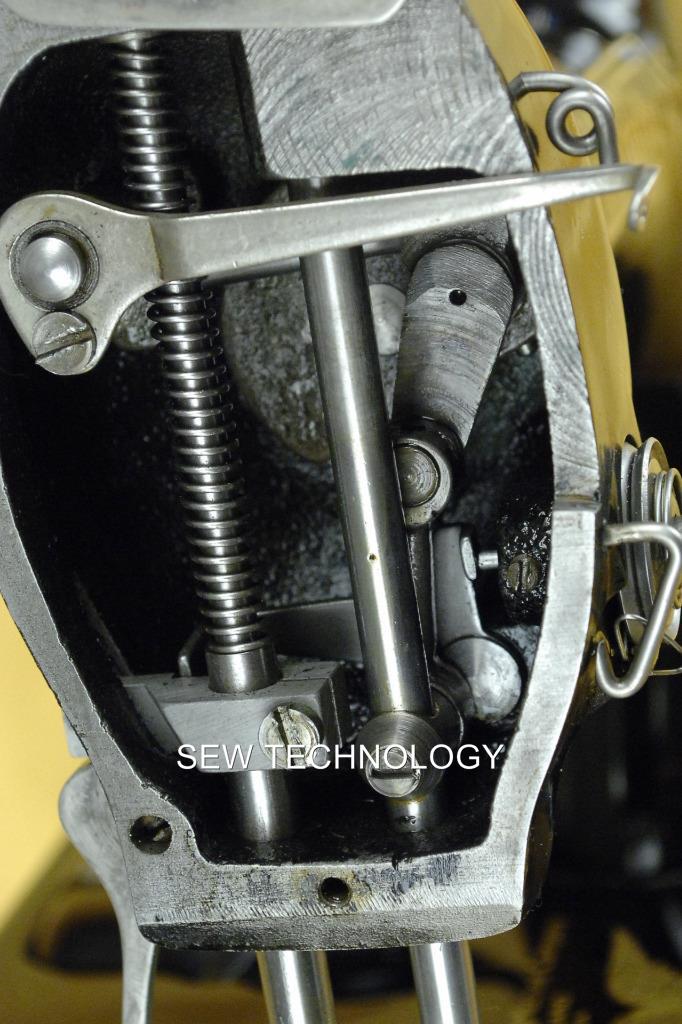

HERE IS A PIC SHOWING MOTOR IN RE-BUILDING PROCESS

![]()

ALL WIRING AND ELECTRICAL COMPONENTS INSPECTED AND REPLACED

BOBBIN ASSEMBLY REBUILT

BOBBIN REWINDER REBUILT

ALL GREASE CLEANED FROM GEARS

TENSIONER REBUILT

FOOT PEDAL REBUILT

ALL RUBBER, FELT AND WEAR COMPONENTS REPLACED

FEED DOGS ARE SHARP AND IN EXCELLENT CONDITION

THE TAKE UP LEVER BEARING IS USUALLY FROZEN, WE REMOVE AND SERVICE

COMPLETE REWIRE OF MACHINE

EVEN THE SMALLEST PARTS ARE ULTRASONICALLY CLEANED

COMPLETE ADJUSTMENT OF MACHINE

SAMPLE SEWING FROM BOTH SIDES WITH TWO DIFFERENT COLOR THREADS TO SHOW BALANCED STITCH

OUR TECHNICIAN HAS ALMOST 30 YRS EXPERIENCE AND SPENDS 8-10 HOURS ON EVERY MACHINE...EVEN ONE OF THIS QUALITY

INCLUDES 90 DAY WARRANTY ON PARTS AND LABOR

IF YOU ARE IN THE MARKET FOR A GREAT Sewhandy THIS IS IT

ACCESSORIES INCLUDED:

3 BOBBINS

Ruffler Foot

GENERAL PURPOSE FOOT

5 BINDER FOOT

GATHERING FOOT

TUCKER FOOT

FELLER FOOT

SEAM GUIDE

FOOT CONTROL

MANUAL

NOTE ABOUT INDUSTRIAL MACHINES

WHAT WE CONSIDER INDUSTRIAL STRENGTH HAS TO PASS THE FOLLOWING CRITERIA.

1) ALL METAL CONSTRUCTION. ALL DRIVE COMPONENTS MUST BE A STEEL OR METAL ALLOY

2) HAS A MINIMUM PRESSER FOOT CLEARANCE OF 5/16" AND WILL SEW VIRTUALLY ANY FABRIC THAT WILL FIT IN THAT SPACE

3) INTERNAL MOTOR SYSTEM

THIS DIFFERS FROM A TRUE INDUSTRIAL MACHINE BY THE FOLLOWING

1) DOES NOT WEIGH 200LBS AND TAKE UP A 2 FT BY 5FT SPACE

2) DOES NOT HAVE AN EXTERNAL BELT DRIVEN MOTOR THAT IS MANY TIMES 220V POWER

3) DOES NOT HAVE AN OIL PAN AND PUMP TO CIRCULATE OIL IN THE HEAD OF MACHINE THAT MUST BE CHANGED ON A REGULAR BASIS

4) IS NOT DIFFICULT TO CONTROL AND SLOW SPEEDS (MOST INDUSTRIAL MACHINES ARE DESIGNED TO OPERATE AT VERY HIGH SPEEDS)

*Which means all wear and moving parts were removed ...dye checked for micro cracks, inspected for wear, and reinstalled.